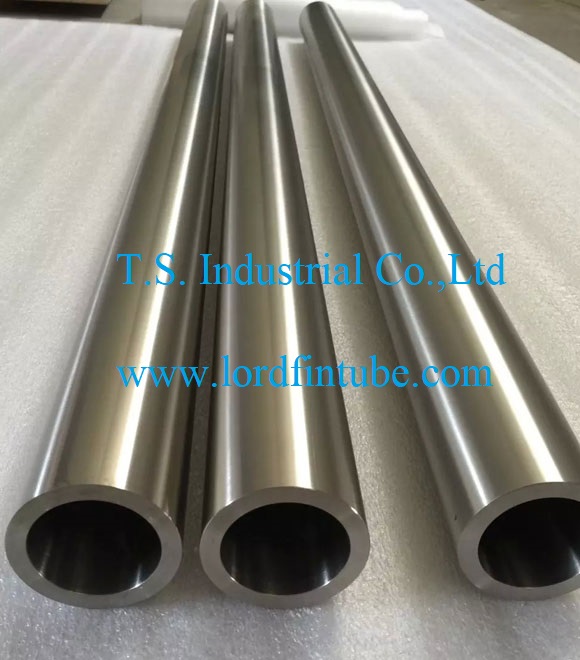

Products Description

Introduction to Seamless Nickel-Based Alloy Pipes

Nickel-based alloys represent a class of alloys known for their combination of high strength and notable resistance to oxidation and corrosion, particularly in elevated temperatures ranging from 650 to 1000 °C. Seamless tubes made from nickel-based alloys find extensive applications across various industries, including petroleum, chemical, high-pressure boilers, nuclear power, aviation, marine engineering, and environmental engineering. Key standards for these tubes include ASTM B 161/ASME SB161, B 163/SB 163, B 751/SB 751, B775/SB 775, B 829/SB 829, ASTM B 127/B 163/B 165/B 366/B 751/B 775/B 829/ASME SB127/SB163/SB165/SB366, and ASTM B163/B407/B751/B775/B829/ASME SB 163/SB 407/SB 751/SB 775/SB 829. Some of the commonly used materials are UNS N02201, UNS N02200, UNS N04400, UNS N06601, UNS N06625, UNS N06600, UNS N06690, UNS N10276, UNS N08800, UNS N08020, UNS N08825, UNS N08810, and N08811.

Compared to standard stainless steel, nickel-based alloys exhibit superior qualities in terms of high-temperature resistance, corrosion resistance, and high strength. These attributes make them suitable for harsh conditions involving strong acids, alkalis, and high temperatures.

- Seamless Nickel 200 Tube:

Based on their primary characteristics, nickel-based alloys can be categorized into several types, including nickel-based heat-resistant alloys, corrosion-resistant alloys, wear-resistant alloys, precision alloys, and shape memory alloys.

- Nickel-based Heat-Resistant Alloy:

These alloys, such as nickel-chromium (Ni-Cr) alloys, incorporate elements like chromium, tungsten, molybdenum, cobalt, aluminum, titanium, boron, and zirconium. Chromium and aluminum primarily contribute to oxidation resistance, while other elements offer solid solution strengthening, precipitation strengthening, and grain boundary strengthening. Notable representatives include Incoloy alloys like Incoloy 800 and Inconel 600.

- Nickel-based Corrosion-Resistant Alloy:

Featuring elements like copper, chromium, and molybdenum, these alloys offer excellent overall performance and resist various acid corrosions and stress corrosion. They find use in producing corrosion-resistant parts for industries like petroleum, chemical, and electric power. Examples include Hastelloy alloys like Hastelloy C-276 and Monel alloys such as Monel 400.

- Nickel-based Wear-Resistant Alloy:

These alloys incorporate elements like chromium, molybdenum, tungsten, as well as trace amounts of antimony, bismuth, and indium. Apart from wear resistance, they also display resistance to oxidation, corrosion, and welding.

- Nickel-based Precision Alloys:

This category encompasses soft magnetic alloys, precision resistance alloys, and electrothermal alloys.

- Nickel-based Corrosion Resistance Alloy:

Comprising 50% (at)% titanium, these alloys exhibit a shape memory effect with a recovery temperature around 70 °C. They are commonly used in crafting self-expanding structural components for spacecraft and aerospace industry applications.

As industries worldwide advance, especially in specialized environments or under unique requirements, the demand for seamless pipes with exceptional properties grows. Ordinary stainless steel seamless pipes may fall short of these demands, while the superior attributes of nickel-based alloy seamless pipes position them for a prominent role in future applications.

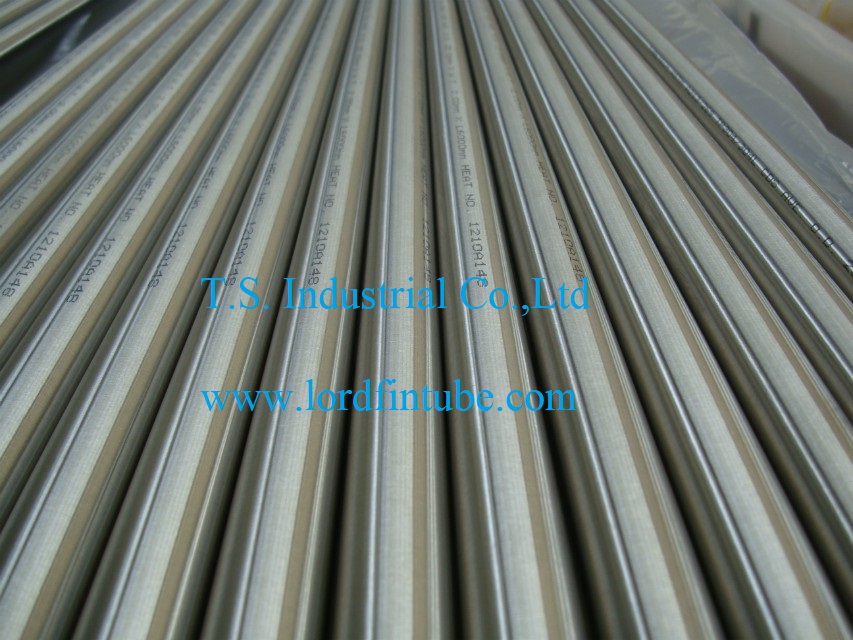

- U Bend Nickel-based Alloy Tubes:

U-bend nickel-based alloy tubes can be manufactured from a range of nickel-based alloys, each chosen for its specific combination of attributes. The alloys high-temperature resistance, corrosion resistance, and exceptional mechanical properties make U-bend tubes made from nickel-based alloys particularly well-suited for demanding conditions and critical applications.

The selection of the appropriate nickel-based alloy for U-bend tubes depends on factors such as the operating environment, temperature range, and the specific medium being transported through the tubes. Examples of commonly used nickel-based alloys for U-bend tubes include Inconel alloys, Hastelloy alloys, and Monel alloys.