Single H-type fin tube basic introduction and selection advantages

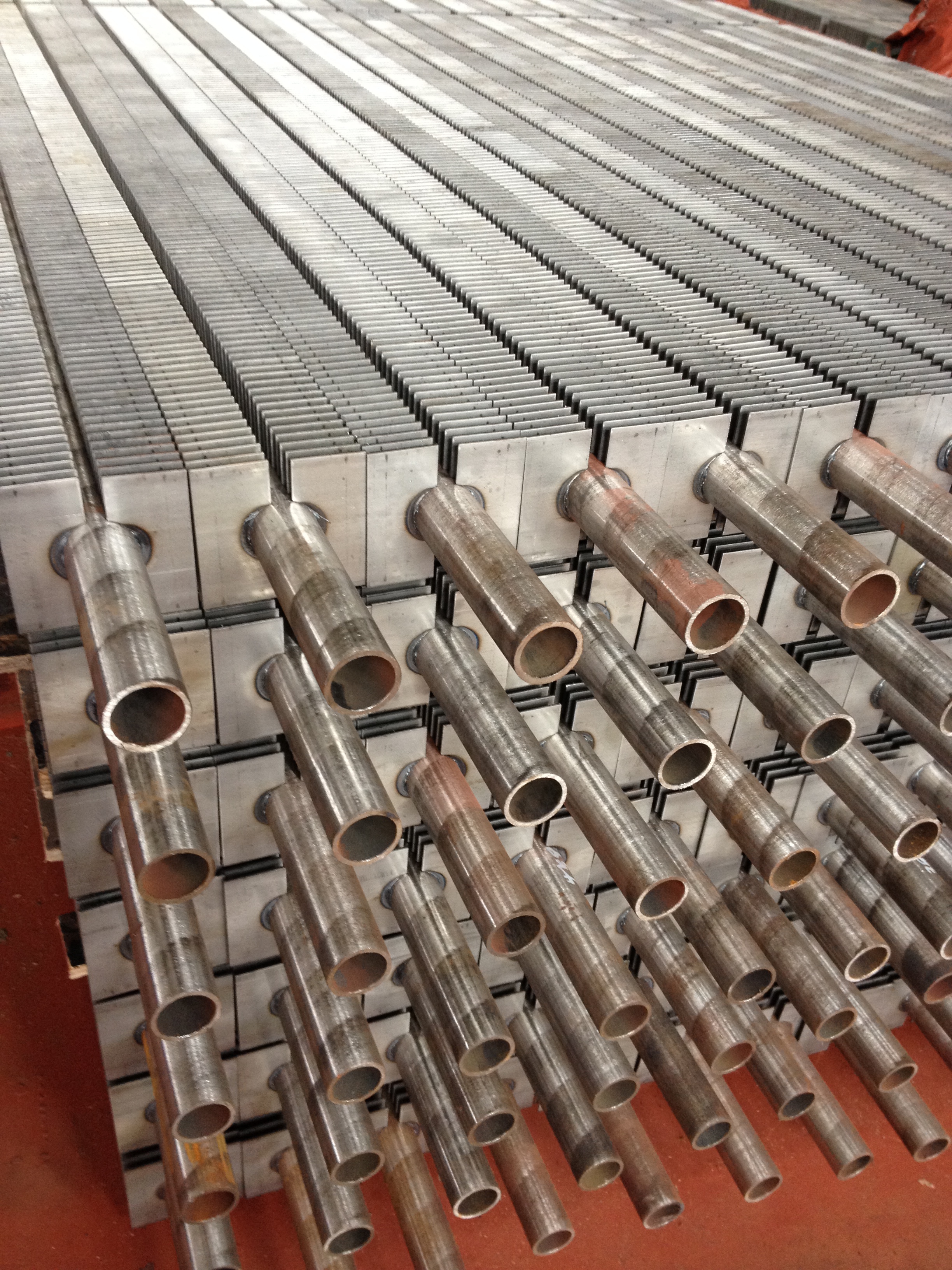

The single H-shaped finned tube is an advanced heat exchange element renowned for its high efficiency and enhanced thermal performance. Named for its distinctive "H"-shaped cross-section, this design is widely employed in industrial heat exchangers, particularly in demanding environments such as power plants and metallurgical systems.

1. Single H-Shaped Finned Tube Structural Features

Geometry

The single H-type finned tube comprises a base tube (plain tube) and rectangular fins welded symmetrically on both sides. The fins are perpendicular to the base tube, forming an H-shaped profile (see diagram below). A gap channel of controlled width is maintained between the fins, creating an optimized "flue gas corridor" for improved airflow distribution.

Base tube materials: Carbon steel, stainless steel, or alloy steel (selected based on temperature and corrosion resistance requirements).

Fin materials: Typically match the base tube, though specialized options (e.g., ND steel, Corten steel) are used for high-temperature and abrasive environments.

Welding Process

High-frequency resistance welding or brazing ensures a strong, low-resistance bond between fins and the base tube. The robust construction withstands thermal stress, vibration, and mechanical wear, ensuring long-term durability.

2. Single H-Shaped Finned Tube Working Principle

Enhanced Heat Transfer

The fins expand the heat transfer surface area by 3–5 times, significantly improving thermal exchange efficiency.

The gap between fins induces turbulence, disrupting the boundary layer and boosting the heat transfer coefficient.

Self-Cleaning Capability

The open-channel design allows high-velocity flue gas to prevent dust accumulation, making it ideal for high-particulate environments (e.g., coal-fired boiler exhaust systems).

3. Single H-Shaped Finned Tube Core Advantages

|

Feature |

Single H-Type Finned Tube |

Spiral Finned Tube |

Longitudinal Finned Tube |

|

Heat Transfer |

High (turbulent flow, no dead zones) |

Moderate (prone to fouling) |

Direction-specific |

|

Dust Resistance |

Excellent (open channel, low deposit buildup) |

Poor (dust accumulates in grooves) |

Moderate |

|

Wear Resistance |

High (rigid structure, durable materials) |

Low (vulnerable to abrasion) |

Medium |

|

Pressure Drop |

Low (straight flow path) |

High (spiral increases resistance) |

Moderate |

Application Scenarios

Single H-Type: High-temperature, high-dust, and high-wear applications (e.g., power plant boilers, steel mills).

Spiral Finned Tube: Petrochemicals, HVAC (cleaner media).

Sleeve Finned Tube: Low-pressure systems (e.g., refrigeration, automotive radiators).

Longitudinal Finned Tube: Gas heaters, specialized industrial processes.

Conclusion: The single H-type finned tube outperforms alternatives in harsh industrial settings, offering superior heat transfer, lower maintenance, and extended service life.

4. Single H-Shaped Finned Tube Installation & Maintenance

Installation Guidelines

Arrangement: Typically installed in series, with fins aligned parallel to fluid flow to minimize pressure drop.

Orientation: Ensure proper alignment to maximize turbulence and self-cleaning effects.

Maintenance Requirements

Inspect welds periodically for cracks (critical in high-temperature, high-vibration environments).

For high-sulfur flue gas, use corrosion-resistant materials (e.g., aluminized coatings). The single H-type finned tube delivers unmatched heat transfer efficiency, durability, and low maintenance in extreme industrial conditions. Its unique H-shaped design outperforms conventional smooth and spiral finned tubes, making it the preferred choice for power generation, metallurgy, and heavy industries.

Single H-type fin tube