Spiral Fin Tube Heat Exchangers in Modern Industry

Spiral Fin Tube Heat Exchangers

Heat exchangers are the backbone of industrial thermal management. Among them, spiral fin tube heat exchangers stand out for their unmatched ability to transfer heat efficiently in compact spaces. Well explore how these innovative devices work, their advantages over traditional designs, and why industries worldwide are adopting them to cut costs and boost sustainability.

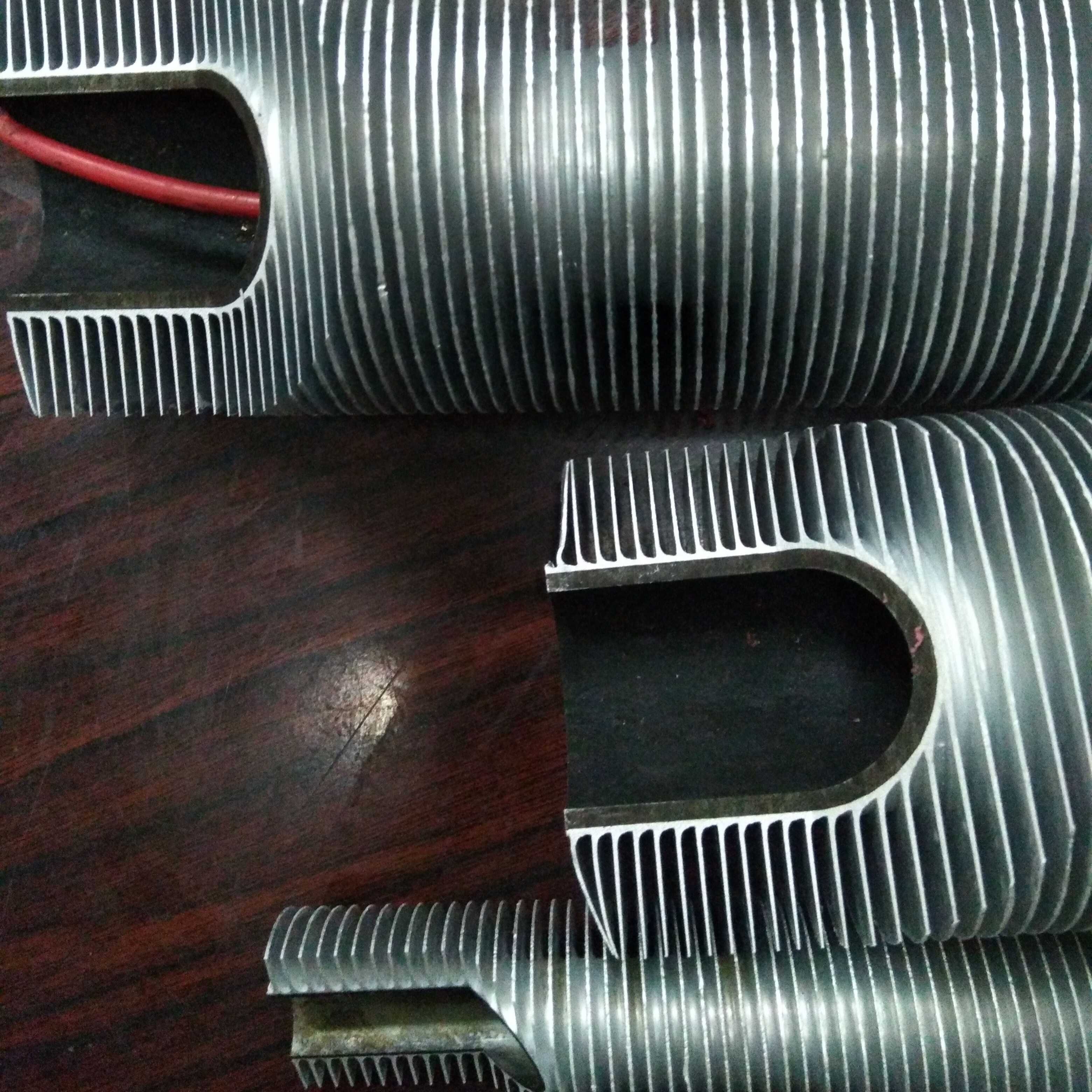

Spiral Fin Tube Heat Exchangers Design

Unlike conventional smooth-tube designs, spiral fin tube heat exchangers feature helical fins welded or extruded onto the tubes exterior. This simple yet revolutionary design offers three critical advantages:

- Expanded Surface Area: The spiral fins increase contact area by up to 300% vs. bare tubes, accelerating heat transfer.

- Turbulence Enhancement: The helical shape disrupts laminar flow, forcing fluids to mix and improving thermal exchange.

- Space Optimization: Achieve higher performance in 40% less space compared to shell-and-tube models.

Technical Specifications

Spiral fin tubes typically feature fins with heights ranging from 5-20mm and pitches of 2-8mm, depending on application requirements. The fin-to-tube ratio can reach up to 15:1, significantly enhancing heat transfer efficiency.

Spiral Fin Tube Heat Exchangers Materials

Manufactured from stainless steel, Inconel®, or titanium, these exchangers withstand harsh industrial environments:

| Material | Temperature Range | Corrosion Resistance | Typical Applications |

|---|---|---|---|

| Carbon Steel | -20°C to 400°C | Moderate | Boilers, air heaters |

| Stainless Steel 304/316 | -200°C to 800°C | High | Chemical processing, food industry |

| Inconel 600/625 | Up to 1150°C | Excellent | High-temperature furnaces, aerospace |

| Titanium | Up to 600°C | Exceptional | Marine applications, chlor-alkali |

Spiral Fin Tube Heat Exchangers Performance

Thermal Efficiency

Spiral fin designs achieve 20-35% higher heat transfer rates than traditional exchangers, slashing energy consumption in processes like:

- Gas turbine cooling

- Waste heat recovery

- Refrigeration cycle optimization

Compact Design

A 2023 study by Thermal Engineering Journal found spiral fin units deliver equivalent performance to shell-and-tube models in 60% less space – ideal for retrofitting aging plants.

Corrosion Resistance

Manufactured from specialized alloys, these exchangers withstand:

- Chemical processing (pH 2-12)

- Marine/salty atmospheres

- High-temperature flue gases (up to 650°C)

Maintenance Advantages

The self-cleaning fin design reduces fouling by 50% compared to flat-fin alternatives, cutting downtime in oil refineries and power plants.

Economic Benefits

A Gulf Coast petrochemical plant reported $2.8M annual savings after switching to spiral fin exchangers, with payback in under 18 months.

Spiral Fin Tube Heat Exchangers Applications

| Industry | Use Case | Performance Gains |

|---|---|---|

| Oil & Gas | Crude oil cooling | 28% reduced pumping costs |

| Power Generation | Condenser optimization | 15% lower water usage |

| HVAC | Data center cooling | 22% energy savings (ASHRAE data) |

| Chemicals | Acid vapor condensation | 40% longer service life |

| Marine | Seawater cooling systems | Reduced corrosion maintenance |

Case Study Highlight

A Saudi Arabian refinery replaced 12 shell-and-tube units with spiral fin heat exchangers, achieving:

- 25% better heat recovery

- $1.2M/year energy cost reduction

- 30% smaller installation footprint

Spiral Fin Tube Heat Exchangers Comparison

| Feature | Spiral Fin Tube | Shell & Tube | Plate Heat Exchanger |

|---|---|---|---|

| Heat Transfer Efficiency | High (20-35% better) | Moderate | High |

| Space Requirements | Compact (40-60% less) | Large | Compact |

| Fouling Resistance | Excellent | Poor | Moderate |

| Pressure Handling | Very High (up to 3000 psi) | High | Moderate |

| Temperature Range | Very Wide (-200°C to 1150°C) | Wide | Limited |

| Maintenance Requirements | Low | High | Moderate |

Spiral Fin Tube Heat Exchangers Installation

4 Steps to Successful Implementation:

- Audit Existing Systems: Identify high-energy zones using thermal imaging.

- Simulate Performance: Use ANSYS or SolidWorks Flow Simulation to model gains.

- Material Selection: Match alloys to operational stressors (temperature, pH, pressure).

- Lifecycle Cost Analysis: Factor in energy savings, maintenance, and disposal.

Frequently Asked Questions

Spiral Fin Tube Heat Exchangers

The next generation of spiral fin tube heat exchangers integrates:

- IoT Sensors: Real-time monitoring of fouling and efficiency

- Additive Manufacturing: Custom fin geometries for niche applications

- Nano-Coatings: Graphene-enhanced surfaces for 50% better corrosion resistance

Global Market Insight projects a 6.8% CAGR for spiral fin exchangers through 2030, driven by decarbonization mandates.

Spiral Fin Tube Heat Exchangers

For engineers prioritizing energy efficiency, space savings, and low lifecycle costs, spiral fin tube heat exchangers deliver measurable ROI. As industries face tighter emissions regulations, this technology provides a proven path to greener operations without sacrificing performance.When specifying spiral fin tube heat exchangers, consider factors such as fluid properties, operating temperatures, pressure drops, and potential fouling mechanisms to ensure optimal performance and longevity.