Stainless SS304L fin tubes|Stainless SS304L fin tubes

Stainless SS304L Fin Tubes

Stainless SS304L fin tubes are specialized heat transfer components engineered for superior performance in demanding industrial applications. These tubes combine the exceptional corrosion resistance of SS304L stainless steel with enhanced heat transfer efficiency through integrated fins.

What are Stainless SS304L Fin Tubes?

SS304L fin tubes represent advanced heat transfer technology, manufactured from SS304L stainless steel - a low-carbon variant renowned for exceptional corrosion resistance and superior weldability. These specialized tubes incorporate fins made from materials including SS304, steel 409, carbon steel, or aluminum to dramatically improve heat exchange efficiency.

Base Tube Material Specifications

SS304L Stainless Steel: The core tube is precision-manufactured from SS304L material, conforming to ASTM/ASME A/S249/269/213/312 standards. The low-carbon composition significantly reduces carbide precipitation risks during welding processes, substantially enhancing corrosion resistance in aggressive environments.

Available Fin Materials

SS304 Stainless Steel

Fins manufactured from the same stainless steel family, ensuring excellent corrosion resistance and long-term durability.

Steel 409

Ferritic stainless steel offering superior mechanical properties and exceptional high-temperature corrosion resistance.

Carbon Steel

Cost-effective solution ideal for applications where extreme corrosion resistance is not the primary requirement.

Aluminum

Provides outstanding thermal conductivity, perfect for applications demanding maximum heat transfer efficiency.

Types of SS304L Fin Tubes

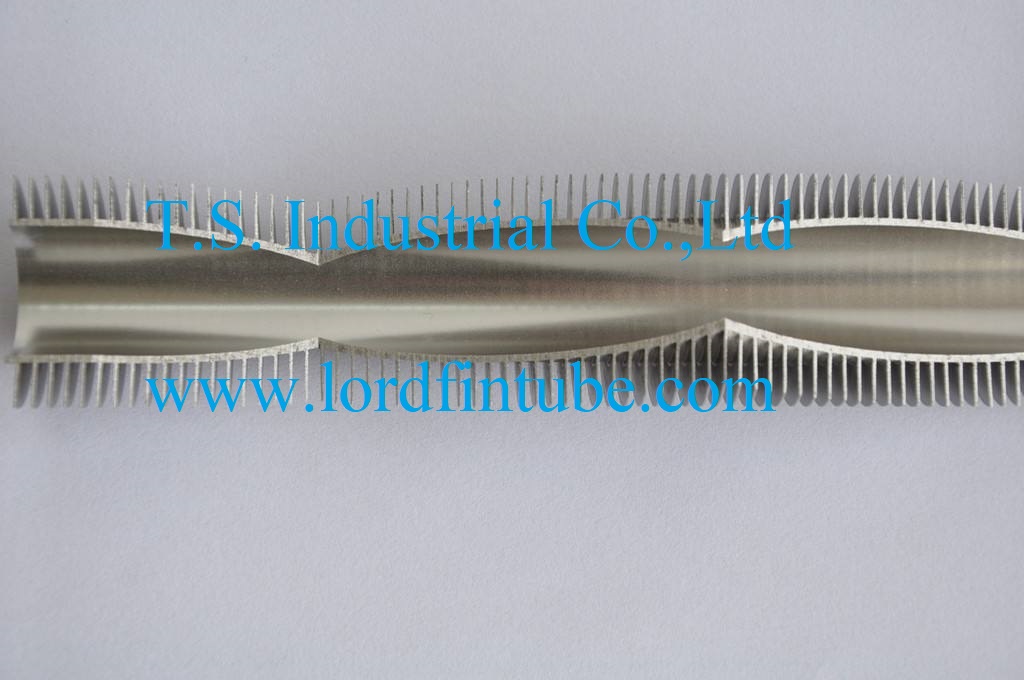

Extruded Type Finned Tube

Fins are extruded directly from the base tube material, creating an integral bond that ensures maximum heat transfer efficiency and structural integrity.

High-Frequency Welded Finned Tube

Advanced high-frequency welding technology attaches fins to the base tube, delivering robust bonds capable of withstanding extreme stress conditions.

Laser Welded Finned Tube

Utilizes precision laser welding for fin attachment, providing superior weld quality with minimal thermal distortion and exceptional durability.

SS304L Fin Tubes - Precision Engineered for Optimal Heat Transfer

Why Choose Stainless SS304L Fin Tubes?

- Superior Corrosion Resistance: SS304L provides exceptional resistance to atmospheric conditions and chemical environments

- Cost-Effective Performance: More economical than SS316L while maintaining excellent performance characteristics

- Enhanced Weldability: Low carbon content minimizes carbide precipitation during welding processes

- Excellent Mechanical Properties: Maintains strength and toughness across wide temperature ranges

- Material Versatility: Compatible with multiple fin materials for customized application solutions

- Extended Service Life: Corrosion resistance and mechanical strength ensure long-term reliability

- Broad Application Range: Suitable for diverse industrial applications and operating conditions

- Temperature Resilience: Consistent performance in both high and low-temperature environments

- Non-Magnetic Properties: Ideal for applications requiring minimal magnetic interference

Testing and Inspection of SS304L Fin Tubes

| Test Method | Purpose | Procedure |

|---|---|---|

| Chemical Composition Analysis | Verify SS304L material compliance with standards | Spectroscopy or X-ray fluorescence (XRF) analysis |

| Mechanical Property Testing | Assess tensile strength, yield strength, elongation, hardness | Tensile testing machines and hardness testers |

| Fin-Tube Bond Inspection | Verify integrity of fin-to-tube bond | Ultrasonic testing (UT) or eddy current testing (ECT) |

| Hydraulic Testing | Ensure pressure integrity without leakage | Water pressurization to specified levels |

| Pneumatic Testing | Leak detection verification | Air/gas pressurization with bubble detection |

| Microstructure Examination | Identify material defects or inconsistencies | Optical microscopy or scanning electron microscopy (SEM) |

| Microhardness Testing | Evaluate hardness in specific zones | Vickers or Knoop hardness testers |

| HAZ Inspection | Examine weld-affected areas | Metallographic examination and hardness testing |

SS304L Fin Tubes Applications

Power Generation Plants

Heat exchangers, boilers, and economizers for improved thermal efficiency and waste heat recovery

Natural Gas Systems (NGS)

Air-cooled heat exchangers for natural gas processing and transportation systems

Refinery Operations

Various heat exchangers and air coolers in corrosive refinery environments

Petrochemical Industry

Heat exchangers, condensers, and chemical processing equipment

Air-Heating Systems

Air preheaters and heating equipment for exhaust gas heat recovery

Industrial Heat Exchangers

Various heat transfer equipment across multiple industrial sectors

Economizer Systems

High and low-temperature economizers in power plants and industrial boilers

HVAC Systems

Heating, ventilation, and air conditioning applications requiring efficient heat transfer

Typical Specifications for Stainless SS304L Fin Tubes

| Parameter | Specification |

|---|---|

| Material of Construction | SA213TP304L |

| Tube Size | 25mm O/D × 2.5mm Thk (Min) × 1200 mm Length |

| Fin Material | SS304L |

| Fin Size | 45mm O/D × 10mm Fin Height × 1mm Thk × 6mm Pitch |

| Finned Length | 1200 mm |

| Fin Density | 04 Fins per inch |

| Finning Type | Spiral Wound Continuous Welded |

Technical: Stainless SS304L fin tubes offer an optimal combination of corrosion resistance, thermal efficiency, and cost-effectiveness for demanding industrial applications. Their versatility across multiple industries and operating conditions makes them the preferred choice for engineers and specifiers worldwide.