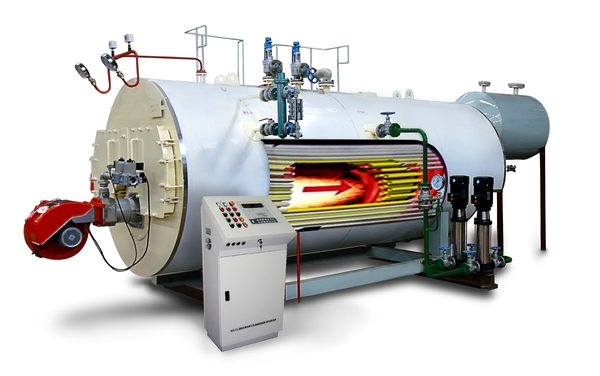

Steam boiler with finned tube

2023-12-12Leave a message

What is steam boiler?

A steam boiler is a thermal energy conversion device used to heat water and generate steam, commonly employed in industrial, energy production, and heating systems. Below is a detailed introduction to steam boilers:

Steam Boiler Main Components:

1. Furnace:This is the area where fuel (such as coal, natural gas, oil) is burned. The heat generated from the combustion is used to heat water.

2. Boiler Piping System:The boiler piping system includes water pipes and steam pipes, the design of which depends on the type of boiler. Water-tube boilers and fire-tube boilers have different pipe structures.

- Water-Tube Boiler:Water flows through the pipes, getting heated and converted into steam. Water-tube boilers are typically used in high-pressure and high-temperature applications.

- Fire-Tube Boiler:The heat produced from combustion is transferred to water through tubes (fire tubes), heating the water to produce steam.

3. Control System:This system monitors and controls the operation of the boiler. It includes temperature, pressure, and combustion control systems to ensure safe and efficient operation.

4. Fuel Supply System:Supplies fuel to the combustion chamber, which can be solid, liquid, or gaseous fuel.

5. Steam Discharge System:Transports the generated steam to the desired location for heating, power generation, or industrial processes.

Steam Boiler Working Principle:

1. Fuel Combustion:Fuel burns in the furnace, generating high-temperature and high-pressure flue gas.

2. Heating Water:Flue gas transfers heat to water through pipes, heating the water and converting it into steam.

3. Steam Transfer:The produced steam is transported through pipes to where it is needed, such as generators, heating systems, or industrial processes.

4. Circulation System:In some systems, water and steam can circulate back to the boiler through a circulation system for reheating, improving energy efficiency.

Steam Boiler Types:

1. Fire-Tube Boiler:Flue gas passes through tubes (fire tubes) to transfer heat to water.

2. Water-Tube Boiler:Water flows through tubes, and flames surround the tubes to heat the water.

3. Electric Boiler:Uses electricity directly to heat water.

4. Steam Generator:Specially designed to generate steam, often used in specific applications such as nuclear power plants.

Steam Boiler Applications:

1. Industrial Heating:Used to heat air, water, or other fluids in industrial processes.

2. Power Generation:Employed in power plants to generate steam for driving turbines and generators.

3. Heating Systems:Utilized for heating buildings and providing hot water.

4. Chemical Processes:Used in some chemical production processes to provide heat.

5. Food Processing:Applied in the food industry for cooking, baking, and other operations.

Steam Boiler Safety Considerations:

Using steam boilers requires adherence to a series of safety standards and regulations, including regular inspections, maintenance, and monitoring, to ensure the equipments safety and efficient operation.

Why steam boilers typically use finned tubes?

Finned tubes are a design where fins are attached to the surface of tubes to increase the tubes surface area, enhancing heat exchange efficiency. This is crucial for steam boilers as efficient heat exchange can increase the boilers thermal efficiency, reducing energy losses.

The working principle of finned tubes involves increasing the heat transfer capacity by augmenting the tubes surface area. These fins are usually attached along the length of the tube, forming a structure similar to a radiator. This allows heat to be more effectively transferred to the surrounding air or fluid, improving heat exchange efficiency.

In steam boilers, finned tubes are often employed for the following reasons:

1. Improved Thermal Efficiency: By increasing the surface area of the finned tubes, the heat generated from fuel combustion can be more effectively transferred to the water in the boiler, producing more steam.

2. Reduced Flue Gas Temperature: Finned tubes can also be used to lower the temperature of flue gas, causing water vapor in the flue gas to condense, releasing additional latent heat and thereby increasing the overall system efficiency.

3. Reduced Boiler Size: Because finned tubes can enhance heat exchange efficiency, in some cases, more compact boiler designs can be implemented, occupying less space.