Lord Fin Tube-T-shaped fin tube

What is T-shaped fin tube?

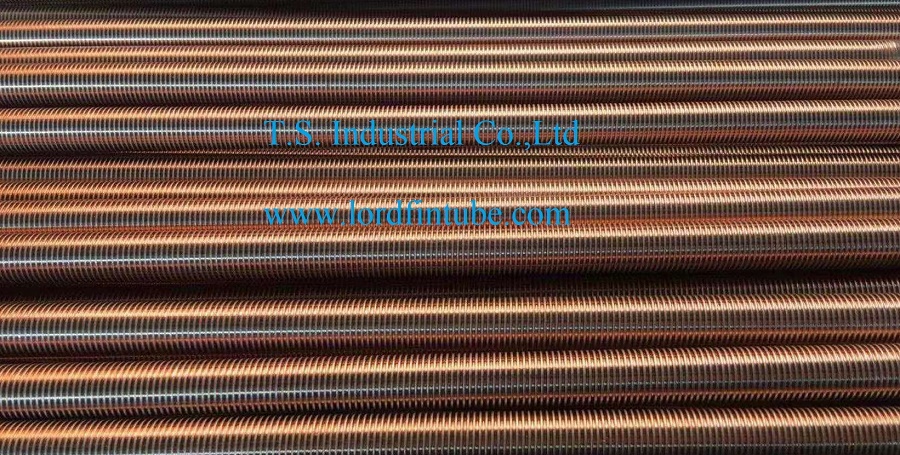

T-shaped fin tube is a kind of high-efficiency heat exchange tube formed by rolling processing of smooth tube. Its structural feature is that a series of spiral ring T-shaped tunnels are formed on the outer surface of the tube. When the medium outside the tube is heated, a series of bubble cores are formed in the tunnel. Due to the surrounding heating state in the tunnel cavity, the bubble core rapidly expands and fills the inner cavity. Continued heating causes the pressure in the bubble to increase rapidly, prompting the bubble from the tube surface Rapidly squirted. A T-shaped fin tube is a type of heat exchanger component used in various industrial applications. It consists of a central tube and fins that extend outward from the tube in a T-shape. The fin arrangement increases the surface area of the tube, allowing for more efficient heat transfer between fluids or gases flowing through the tube and the surrounding environment.

Characteristics of T-shaped finned tube

⑴The heat transfer effect is good. In R113 working medium, the boiling heat transfer coefficient of T tube is 1.6-3.3 times higher than that of smooth tube.

⑵ Conventional smooth tube heat exchangers, only when the temperature of the heating medium is higher than the boiling point or bubble point of the cold medium of 12 ℃ -15 ℃, the cold medium will bubble and boil. T-shaped finned tube heat exchanger only needs a temperature difference of 2 ℃ -4 ℃, the cold medium can be boiled, and the bubbling is fine, continuous and fast, which forms a unique advantage compared with the smooth tube.

⑶The single tube experiment with Freon 11 as the medium shows that the T-tube boiling heat transfer coefficient can reach 10 times that of the smooth tube; the experimental results of the small tube bundle using liquid ammonia as the medium, the total heat transfer coefficient is 2.2 times that of the smooth tube; C3 The industrial calibration of the reboiler of the C4 hydrocarbon separation tower shows that the total heat transfer coefficient of the T-shaped tube is 50% higher than that of the smooth tube at low load, and 99% higher at high load.

⑷ Cheaper than aluminum porous surface heat transfer tube.

⑸ Because the gas-liquid disturbance inside the tunnel is very intense and the gas is ejected along the T-slot at high speed, it is not easy to scale either inside the T-slot or the outer surface of the pipe. This ensures that the equipment can be used for a long time and the heat transfer effect will not be affected by scaling.

T-shaped finned tube usages

The T-shaped fin tube design is commonly used in air-cooled heat exchangers, such as radiators, air coolers, and condensers. The fins attached to the tube enhance heat dissipation by promoting convective heat transfer. This design allows for effective cooling or heating of the fluid inside the tube by facilitating the exchange of thermal energy with the ambient air.

The T-shaped fins can be made from various materials, such as aluminum, copper, or stainless steel, depending on the specific application and desired heat transfer characteristics. The fin tube is typically manufactured by bonding or welding the fins to the central tube, ensuring good thermal conductivity and mechanical strength.

Overall, the T-shaped fin tube design is an efficient solution for applications requiring effective heat transfer in air-cooled systems, enabling better temperature control and energy efficiency.