Products Description

1. What is twisted tube?

The cross-section of the twisted tube is elliptical, which is heat exchange element and the flow path in the tube is spiral, so it is called twist flat tube. In order to facilitate the processing of the connection between the heat exchange element and the tube sheet, the two ends of the elliptical tube are still kept as round. The arrangement of the twist flat tubes in the shell is very compact. The outer edges of adjacent heat transfer tubes keep the spiral point contact to reduce the volume of the heat exchanger and increase the flow space between the heat exchange elements.

Twisted tube is one kind of enhanced heat transfer tubes that were firstly presented by Swiss Allares Company, and then improved by the United States Brown company.

2. Structure and manufacture of twisted tube

The characteristic of twisted tube is that every cross section of the tube is oval, when assemble heat exchangers they can be mixed bundle (that is, the mixed use of twisted tube and bare tube), and can also be a pure twisted tube bundle.

The manufacturing process includes two forming steps: "partial pressure" and "distortion". The tube cross section is ellipse type the ratio of long and short axis is designed according to the flow velocity in heat transfer tube. When the flow rate in tube is low, we can increase the ratio of the long and short axis, or reduce the flow surface.

Seamless steel twisted tubes used for producing heat exchangers are complete ones without joints. Common materials used in steel tubes shows in bellow chart.

|

Material Type |

Material Grade |

Produce Standard |

Supply condition |

|

Carbon steel |

10、20/A1 |

ASTM A179/A192/A210 |

Annealed condition |

|

Low Alloy |

T5/T11/T22 |

ASTM A213 |

Annealed condition |

|

Nickel Alloy |

UNS6625/UNS6852 |

ASTM B444 |

Annealed condition |

|

Titanium |

Grade 2 |

ASTM B338 |

Annealed condition |

|

Alloy of copper |

C68700/C70600/C71500 |

ASTM B111 |

Annealed condition |

|

Austenitic stainless steel |

304/304L |

ASTM A213 |

Pickling & passivation |

|

316/316L |

|||

|

310 |

|||

|

321 |

|||

|

347 |

3. Enhanced heat transfer principles of twisted tube

The unique structure of twisted tube can make the flow in tube pass and shell pass in the spiral motion at the same time, in this way it enhanced the turbulent intensity. The heat transfer coefficient of the twisted tube is 40% higher than the normal one, but the pressure drop is almost the same.

4. Advantages of heat exchanger with twisted tube

|

1 |

Lower pressure drop |

The longitudinal flow allows for a lower relative pressure drop when compared to segmental baffle designs. |

|

2 |

Higher heat transfer efficiency |

Allowing for more surface area in a given shell size, the throughput can potentially be increased based on the application. Increasing the tube-side heat transfer coefficient can provide increased heat transfer, based on the application. |

|

3 |

Less deposit |

No blind zone in the shell |

|

4 |

Elimination of Damage-Induced Vibration |

Due to the generally longitudinal flow pattern of the shell-side fluid and the multi-point support structure of the bundle, the potential for flow-induced damaging vibration is mitigated. |

|

5 |

Potential Fouling Mitigation |

The elimination of shell-side baffles eliminates dead spots where sediment can accumulate and cover heat transfer surface area. |

5. Specification of twisted tube heat exchanger

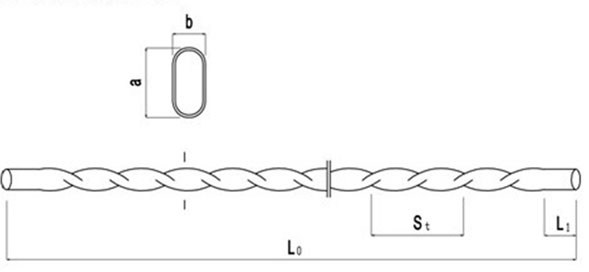

Fig: Basic dimension parameter figure of twisted tube

|

Spec. |

Lead St(mm) |

Long axis a (mm) |

Short axis b (mm) |

Length of bare ends L1 (mm) |

|

Φ8 |

200 |

|

|

Arbitrary length |

|

Φ16 |

200 |

|

|

Arbitrary length |

|

Φ19 |

200 |

23.0 |

13.0 |

Arbitrary length |

|

Φ25 |

200 |

30.5 |

15.5 |

Arbitrary length |

|

Φ32 |

200 |

37.0 |

22.5 |

Arbitrary length |

|

Φ38 |

200 |

|

|

Arbitrary length |

Note: The above table is the basic parameter of standard twisted tube.twisted tube can be manufactured according to St and L , if there are special requirements.

6. Application of the twisted tube

As twisted tube has developed and improved fastly in recent years, it is much more reliable and effective, and almost can be used in all shell and tube heat exchangers. More than 400 twisted tube heat exchangers have been used since 1984, and they can be used in gas-gas, liquid-liquid and liquid-gas heat transfer process, including chemistry, petroleum, food, papermaking, electric power, metallurgy, mining, and urban heating industry.

7. Application example of the twisted tube

In 1997, Lanzhou refinery changed the traditional heat exchangers in the Ketone benzene dewaxing unit into the twist flat-tube heat exchangers, which were designed and fabricated by a local company. According to the process parameters, the HETECH was used for the type selection calculation of twist flat-tube heat exchanger.

Twisted tube, Twist Flate-tube, brown fin twisted tube

Table: Related parameters of benzol-ketone dewaxing process

Item Tube pass Shell pass

Medium Solvent Hot water

Flow rate/kg·h-1 5000.0 20000.0

Operating pressure/MPa 0.18 0.23

Inlet temperature/oC 130.0 200.0

Exit temperature/oC 185.0 190.0

Relative densityd420 0.83 1.0

Temperature when viscometry /oC 50 100 50 100

Viscosity/mm2·s-1 13.4 5.6 0.556 0.296

Fouling resistance/W·(m2·K)-1 0.0002 0.0002

Selection & calculation of the twist flat-tube heat exchanger:

They chose two units of twist flat-tube heat exchangers (the No. is LCLF600-2.5-74.5-6/25-6 (ST = 250)) by calculation instead of the initial two units of bow baffle plate heat exchangers (No. BES800-2.5-145-6/25-6 (B = 300)). The heat transfer surface of every unit nearly saved nearly twice of the original equipment. Considering the pressure drop of shell pass, and it was the first time using this type heat exchanger, we chose DN600mm heat exchanger. In the structural parameters, we still chose Φ 25 mm heat transfer tube, whose tube pitch is 32 mm, arrangement is square turn 45°, to facilitate the flow and the cleaning in the shell pass. We selected the optimal lead of twist flat-tube in single tube heat transfer experiment: 200, 250 and 300 mm. For the same lead twist flat-tube, the heat transfer and resistance performance of Φ 25 mm tube is obviously better than theΦ19 mm tube. The lead also has a direct relation with the heat transfer coefficient, if the lead is too small, flow velocity increased, point contacts of helix increased, it strengthened the function of wake flow, and improved the heat transfer coefficient, but increased the resistance; if the lead is too large, the velocity is almost not change, heat transfer effect is not obvious. Therefore, we chose the lead for 250 mm.

Table: Results of process calculation

Thermal load 248.2kW

The film heat transfer coefficient in tube pass 371.0/W·(m2·K)-1

The film heat transfer coefficient in shell pass 2872.3/W·(m2·K)-1

The total film heat transfer coefficient(clean) 328.6/W·(m2·K)-1

The total film heat transfer coefficient(deposit) 286.3/W·(m2·K)-1

logarithmic mean temperature difference 32.5/oC

Effective mean temperature difference 29.0/oC

correction factor of temperature difference 0.895

The total pressure drop in tube pass 17.7/kPa

The total pressure drop in shell pass 0.6/kPa

Heat transfer area(calculation) 29.9/ m2

Heat transfer area(design) 74.5/ m2

The affluence of heat transfer surface 149.5%

Table: Structure parameters of the heat exchanger

Shell diameter 0.6m

Type Twist flat-tube

Number of heat transfer tubes/

number of tube pass 158/6

Specification Φ25×2.5mm

Length 6m

Tube pitch 32mm

Locate type Rotating Squares

Lead 250mm

Number of shell pass 1

Type of the flow baffle plate Nothing

Heat transfer area 75m2

Outlet diameter of the tube pass 150mm

Outlet diameter of the shell side 150mm

Structure design:

As traditional bow baffle plate heat exchanger, the twist flat-tube heat exchanger is composed of the bundle, shell, tube box, floating head cover and the outside head cover. The main difference is that the structure of the heat transfer tube and tube bundle, other parts, such as fixed tube sheet, floating tube sheet and draft tube is exactly the same.

The two ends of the twist flat-tube keep straight, which make it easy to assemble heat transfer tube and connect tube sheet. Every cross section of twist flat-tubes is oval, the long axis and short axis are determined by the tube pitch.

They can support each other by relying on the points of outer spiral; every tube has four points to contact with its surrounding four tubes. The rest may be deduced by analogy that they support each other and are function as self-supporting. And direction of roating tube in every cross section is required to be consistent, to ensure the mediums spiral flow in the shell pass.

As there are six tube passes, there is no tube in the shell pass on the place of the baffle. Lacking of one side support, it will lose balance, and leakage flow and short circuit may occur. Thus, the baffle was designed.

As the tube bundle is 6 meters long, and deflection is large, without the baffle plate, tube vibration and collapse may occur during operation, and affect service life of equipment. So they designed 8 groups of steel belt strapping bundles outside the tube bundles, it can avoid the tube bundles from getting loose, and strengthen its integrity. Each steel belt added a ring baffle, its outer diameter is 4 ~ 5 mm, less than shell inner diameter. And opened four slide channels were opened from top to bottom of the baffle, so it is embedded two sets of slide damper in vertical direction along the tube bundle. This can prevent by-pass leakage, and facilitate tube bundle into the shell.

There is a draft cylinder in the inlet and outlet of tube bundle. First of all, it can reduce fluid stagnation area caused by gap between the tube and tube sheet, and increase effective heat transfer length of tube; secondly, it can play a supporting role to the tube bundle. Finally, it can reduce erosion of the fluid on heat transfer tube.

Since the cylindrical sectional size of the twist flat-tube is bigger than the bare tube, after the assembly of the bundle, tubes become closer to the inlet and outlet, which will reduce the circulation surface and increase the pressure drop. To solve this problem, the treatments are as below:

A row of tubes remain straight for 500mm from the end near the inlet and outlet, the length of the spiral sect, ion is slightly, , , y reduced, which does little effect on heat transfer performance, but it increases the distance from here to the section and the flow surface of the tube inside the tank and reduces the pressure drop. Opening many small holes on the draft cylinder, can also reduce the pressure drop at the inlet and outlet.

This design uses the strength welding and expansion method, not only ensure the connection strength of tube and tube plate, but also ensure the sealing performance, avoids crevice corrosion.

By the end of 1998, the two devices were used they have ran well so far, and were praised by users. Subsequently, normal pressure device requires many heat exchangers in Lanzhou refinery, processing medium include: crude oil, normal four lines oil, cut four, cut five, cut six oil and sludge etc. which are high-viscosity, and completed the process design and selection calculations, its diameter reduces 1 to 2 level compared with traditional heat exchangers, which can save about 30% of the investment.