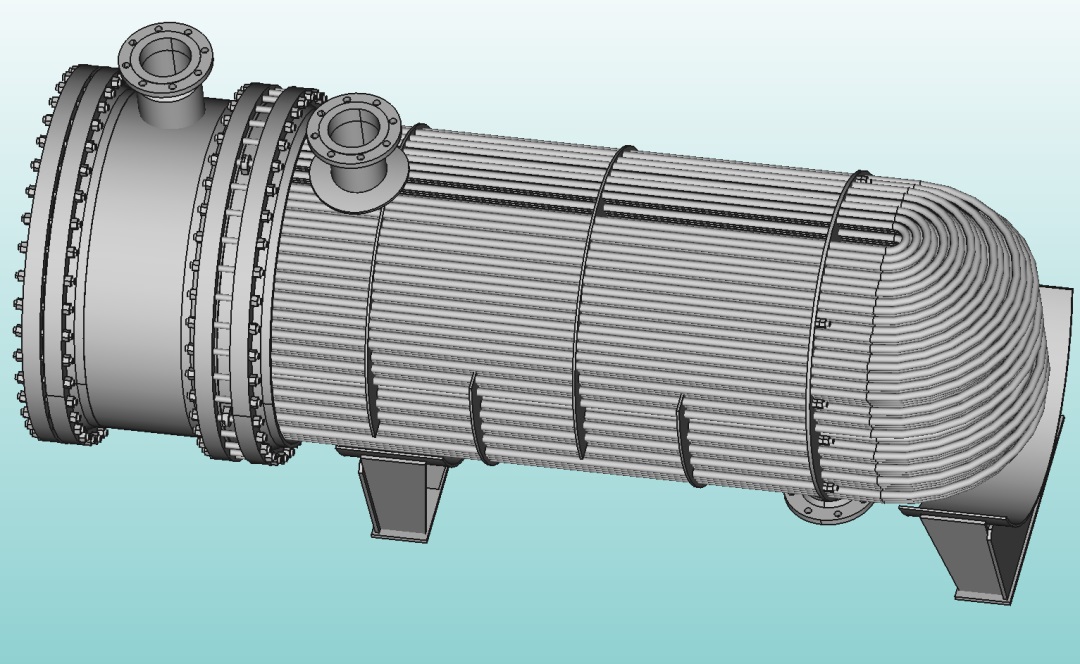

U-shaped heat exchange tubes need to external pressure testing?

The provision in GB/T 151 regarding the need for a hydrostatic pressure test after bending a U-shaped heat exchange tube. What should be done when the shell side is under pressure (the heat exchange tube is subjected to external pressure), especially when the shell side pressure is much higher than the tube side pressure? Is an internal pressure test used instead of external pressure? It is relatively difficult to conduct external pressure tests on U-shaped tubes separately. If internal pressure test is used instead of external pressure, how should the test pressure be selected?

1. Do U-shaped heat exchange tubes need to undergo external pressure testing?

In the GB/T 151 specification, there are:

According to Article 8.3.3.1 of the specification, although U-shaped pipes may withstand external pressure in actual equipment, the test pressure is based on internal pressure, and the pressure value is taken as the higher value of the shell side test pressure.

2. Why U-tubes can be tested with internal pressure instead of external pressure?

According to Articles 4.6.1.6/7 and 4.6.2.3 of GB/T 150.1-2011:

If the stability requirements cannot be met, a leak check should be conducted first, and after passing the test, a pressure test should be conducted. When conducting a pressure test, adjacent pressure chambers should maintain a certain pressure so that at any time during the entire test process (including pressure rise, holding, and release), the pressure difference between each pressure chamber does not exceed the allowable pressure difference. This requirement and allowable pressure difference should be indicated on the drawing

The most typical example is the jacket inner cylinder, which does not require the test pressure of the jacket to test the stability of the inner cylinder. (Note that it doesnt mean we dont consider the test pressure.) So why can we use internal pressure instead of external pressure test?

In the standard definition of GB150, there is a detailed explanation.

The purpose of conducting pressure tests on external pressure vessels under internal pressure is mainly to check the density of welded joints and verify the sealing performance of the sealing structure, rather than to examine the stability of the vessel under external pressure.

For U-shaped pipes, there are no welded joints or sealing structures, but the principle is the same. The pressure test for U-shaped pipes after bending is a new content added to the 2014 version of GB151. The purpose is to avoid possible damage during the bending process and to prevent potential penetrating defects, not to test stability.

For U-shaped tubes, the external pressure they can withstand is quite high, and now SW6 actively checks the internal and external pressure of heat exchange tubes during hydrostatic testing, so it is impossible for external pressure to fail. Before leaving the factory, the heat exchange tubes are subjected to a water pressure test one by one. According to NB/T 47019-2021 "Technical Conditions for Ordering Tubes for Boilers and Heat Exchangers", the pressure test of the heat exchange tubes is based on the MAWP test of the heat exchange tubes, and can even reach up to 20MPa.

Appendix B of the standard, additional requirements for U-shaped heat exchange tubes, has the same testing requirements as GB151. A U-shaped tube, normally bent, cannot have any problems with its internal pressure strength and external pressure stability. The most feared issue is that the bending radius is relatively small, and strong bending can result in large residual stresses and even cracks, which are difficult to detect. To avoid potential hazards, a higher test pressure is used for inspection.

3. Other cases of using internal pressure instead of external pressure

Actually involve using internal pressure instead of external pressure, and there are many examples in pressure vessels. For example, in the case of a nearly symmetrical structure such as a flat plate, the calculated pressure pc in the formula, when the device is under external pressure, is substituted with the absolute value of the pressure, which is definitely not substituted with -0.1. For example, in flange calculation, the external pressure flange can be calculated according to the internal pressure flange.

For example, in the calculation of local stress in WRC, when the membrane stress generated by external pressure is superimposed with the stress generated by external load, the internal pressure formula of the cavity is used without considering instability.

For example, in the PD 5500 specification, the calculated thickness for external pressure hole reinforcement calculation is based on the calculated thickness under internal pressure (absolute value of external pressure). (Slightly different from GB and ASME)