Lord Fin Tube-Waste heat recovery

What is waste heat recovery?

Waste heat recovery refers to the reuse of waste heat generated by industrial processes. The main technologies include heat exchange technology, thermal power conversion technology, and waste heat refrigeration and heating technology.

Characteristics of waste heat resources

Waste heat resource belongs to secondary energy, which is the product of conversion of primary energy or combustible materials, or the heat generated in the fuel combustion process after completing a process. According to temperature grade, industrial waste heat is generally divided into high temperature waste heat above 600 ℃, medium temperature waste heat of 300~600 ℃ and low temperature waste heat below 300 ℃; According to the source, industrial waste heat can also be divided into: flue gas waste heat, cooling medium waste heat, waste steam waste heat, chemical reaction heat, high-temperature products and slag waste heat, as well as combustible waste gas and waste heat.

Industrial waste heat utilization technology

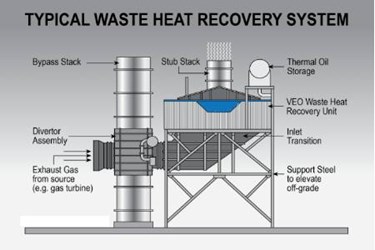

The range of waste heat temperature is wide, and the forms of energy carriers are diverse. Due to the different environments and technological processes and the inherent conditions of the site, the demands of production and life, and the various types of equipment, such as finned tube air preheaters, kiln regenerators, waste heat boilers, low-temperature steam turbines, etc. There are many kinds of common industrial waste heat recovery and utilization methods. According to the characteristics of energy transfer or conversion during the utilization of waste heat resources, the current domestic industrial waste heat utilization technology can be divided into heat exchange technology, thermal power conversion technology, and waste heat refrigeration and heating technology.

Waste heat recovery Heat exchange technology

The waste heat recovery shall be preferentially used for the system equipment or the process flow to reduce the primary energy consumption and minimize the number of energy conversions. Therefore, in the industry, waste heat is often recovered through air preheaters, regenerators, heaters and other heat exchangers to heat combustion supporting air, fuel (gas), materials or workpieces, improve furnace performance and thermal efficiency, reduce fuel consumption and reduce flue gas emissions; Or generate steam and hot water from high-temperature flue gas through waste heat boiler or vaporization cooler for process flow. The utilization of waste heat by this kind of technical equipment does not change the form of waste heat energy, but directly transfers the waste heat energy to the energy consumption process of its own process through heat exchange equipment to reduce primary energy consumption, which can be collectively referred to as heat exchange technology. This is the most direct and efficient economic method to recover industrial waste heat. Finned tubes can greatly improve the waste heat recovery system proformance.The corresponding equipment is various heat exchangers, including traditional heat exchangers and heat pipe heat exchangers of various structures, There are also waste heat steam generators (waste heat boilers).