Products Description

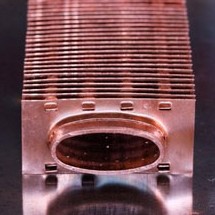

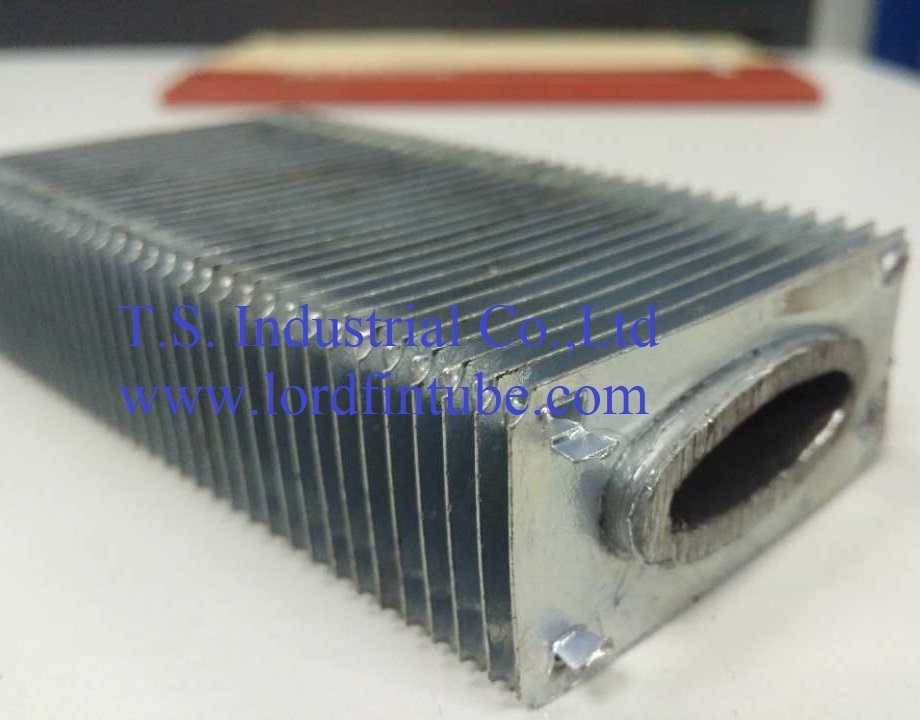

Elliptical Fin Tube|Elliptical Tube With Rectangular Fins| Hot dipped galvanized oval fin tubes

Introducing our elliptical fin tube, featuring hot-dipped galvanized oval fin tubes. This innovative design incorporates an elliptical tube shape along with an aerodynamic airfoil structure, specifically engineered to reduce airflow resistance on the air side. Compared to traditional round tube types, these fins demonstrate enhanced performance characteristics. The hot-dip galvanization process significantly increases the corrosion resistance of these fins, ensuring longevity and durability in diverse environments. Furthermore, these fin tubes offer a compact solution relative to other designs, boasting remarkable heat transfer efficiency.

What is elliptical fin tube or oval fin tube?

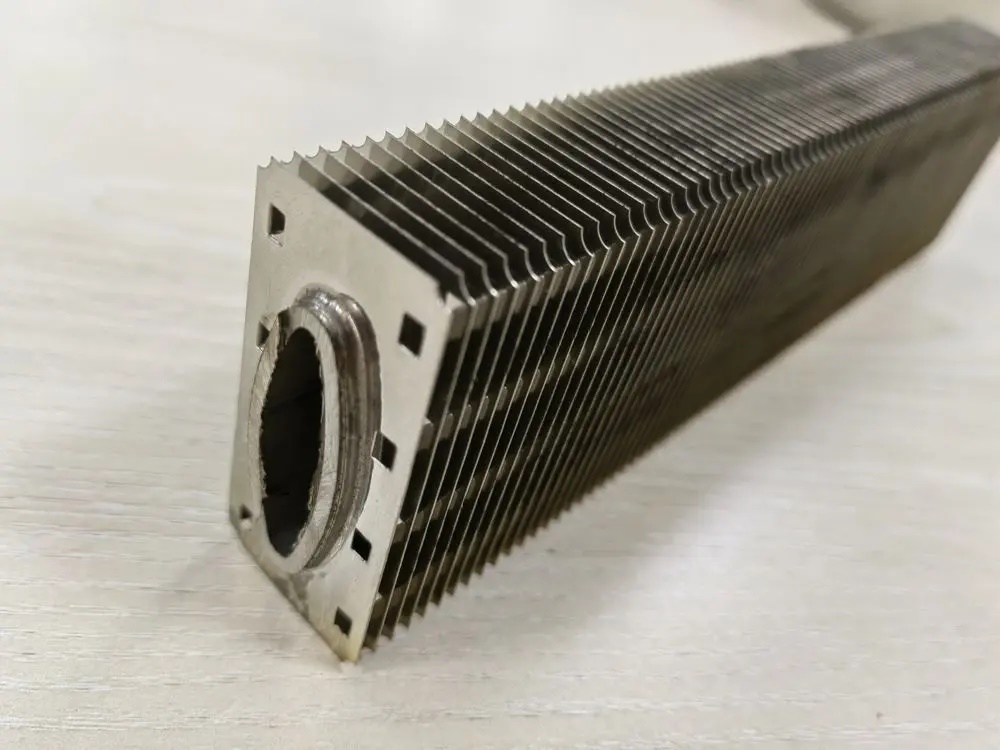

Elliptical fin tube also called oval fin tube. Elliptical finned tubes have two parts, one is elliptical tubes and rectangle fins. The elliptical tube can be seamless steel tube or welded oval steel tube. The fins are carbon steel and in rectangular shape. Furthermore the rectangular fin can be with interrupting holes or without interrupting holes.

Elliptical Finned Tube design utilizes an elliptical shaped tube with an efficient air foil shape to minimize airside flow resistance, While these rectangular fins can improved heat transfer performance characteristics compared to round tube types.

The oval finned tube is a specific kind of heat exchanger featuring an oval-shaped base tube with external rectangular fins. Variants of this design include oval rectangular finned tubes, oval-oval finned tubes, oval circular finned tubes, spiral oval flat tubes, and oval H-shaped finned tubes. These oval finned tubes are becoming increasingly favored due to their enhanced efficiency compared to traditional round finned tubes, making them prevalent in sectors like ethylene production and oil refining.

How about the elliptical fin tube surface treatment?

The corrosion resistance of these fins will be very high after being hot dip galvanized. These fin tubes are very compact compared to other types of fin tubes and their heat transfer efficiency is significant. So its also called Hot dipped galvanized elliptical/oval fin tubes.

How to manufacture the elliptical fin tube?

1. Produce seamless or welded oval steel tube;

2. Punched the rectangular fins through mold on steel coils;

3. Automatically fill the fins into elliptical tubes;

4. Hot dip galvanized the finned tubes. The finned tube dipped in melted zinc tanks. The gap between the fin and the core tube is filled completely by zinc.

The typical elliptical fin tube size:

|

Base Tube O.D (mm) |

Base Tube Thickness (mm) |

Fin Height (mm) |

Fin Thickness (mm) |

Fin Pitch (mm) |

|

36 x 14 |

1.5-3.0 |

55 x 26 |

0.25 |

2.31,2.54,2.82,3.18 |

|

Base Tube Material |

Fin Material |

Tube Length (Mtr) |

||

|

Carbon Steel ,Alloy Steel ,Stainless Steel |

Carbon Steel ,Alloy Steel ,Stainless Steel |

≤ 12 Mtrs |

||

Whats the elliptical fin tube advantage?

1. Compared with round finned tube, elliptical finned tube is easier to achieve compact layout, which reduces the overall volume of the whole heat exchanger, thus reducing the floor area. Minimizes the overall size and footprint of the heat exchanger.

2. Due to the shape characteristics of elliptical finned tubes, the air side resistance is small, and the heat transfer coefficient between fluids increases; The thermal resistance in the tube is relatively small, which increases the heat transfer of the fluid in the tube. Improves the heat transfer coefficient between fluids, boosting efficiency.

3. The heat transfer area of elliptical finned tubes is larger than that of circular tubes with the same cross-sectional area, because the heat transfer perimeter of elliptical tubes is longer under the same cross-sectional area. Offers a larger heat transfer perimeter than circular tubes, enhancing performance.

4. Rectangular steel fins are the most commonly used elliptical finned tubes with high strength. The base tube should not be frozen in winter and has a long service life. Rectangular steel fins ensure durability and longevity, preventing issues like freezing and cracking in cold weather.

5. Since elliptical finned tubes can be arranged more compactly, the front row tubes have a greater impact on the rear row tubes. The external flow resistance of the tubes can be reduced by increasing the fin spacing of the rear row tubes, but the number of tube rows should not be too large. A compact configuration lowers external flow resistance, effectively optimizing air circulation.

6. Elliptical Finned Tubes maximum working temperature reach 400°C.

In order to forward you a promt offer we would be pleased to receive you detailed enquiry including:

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)

Elliptical Fin Tube|Elliptical Tube With Rectangular Fins| Hot dipped galvanized oval fin tubes