What is serrated finned tube economizer?

Serrated Finned Tube Economizer

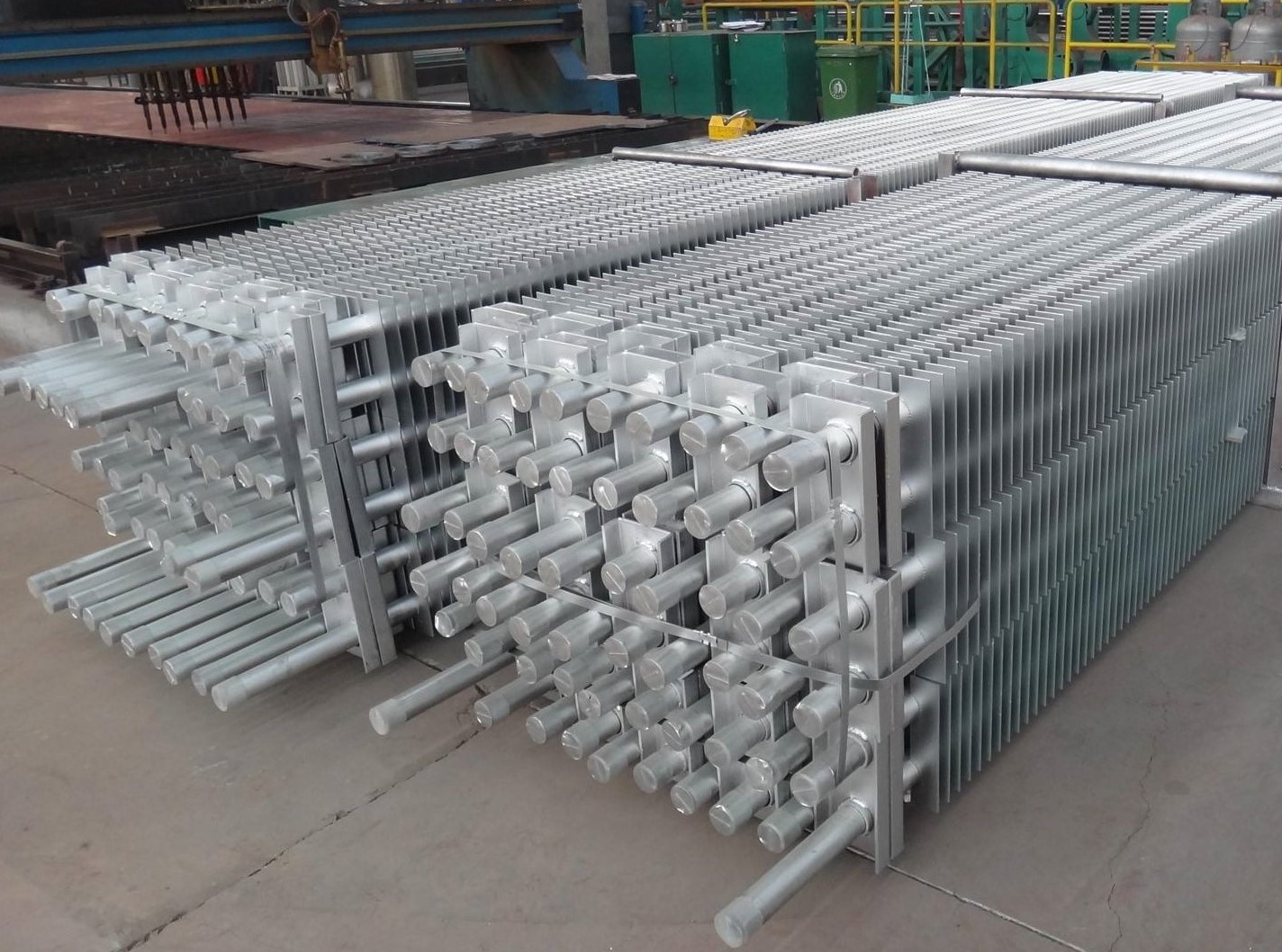

Serrated finned tube economizers represent a significant advancement in heat recovery technology, offering superior thermal efficiency and operational reliability in modern power generation systems. These specialized components are manufactured using high-frequency welding techniques to create serrated fin profiles that dramatically enhance heat transfer capabilities.

Serrated Finned Tube Economizer Technical Specifications and Design Parameters

Design Characteristics

Serrated finned tube economizers feature precisely engineered fin geometry with optimized serration patterns that create turbulence in the flue gas flow, disrupting boundary layers and significantly improving heat transfer coefficients compared to conventional smooth fin designs.

| Parameter | Standard Range | Optimal Performance Zone | Impact on Efficiency |

|---|---|---|---|

| Fin Height (mm) | 12-25 | 15-20 | Direct impact on heat transfer surface area |

| Fin Density (fins/inch) | 3-8 | 4-6 | Balances surface area vs. flow resistance |

| Serration Depth (mm) | 1.5-4.0 | 2.0-3.0 | Enhances turbulence and heat transfer coefficient |

| Tube Material | Carbon Steel, Alloy Steel | SA-210, SA-213 T11/T22 | Determines temperature and pressure limits |

| Operating Temperature (°C) | 250-450 | 300-400 | Affects material selection and thermal stress |

Serrated Finned Tube Economizer Performance Advantages and Engineering Benefits

Enhanced Heat Transfer Efficiency

Serrated fin design increases heat transfer coefficient by 25-40% compared to smooth fin tubes, resulting in more compact economizer designs and reduced material requirements.

Superior Anti-fouling Characteristics

The turbulent flow created by serrated fins minimizes ash deposition and particulate buildup, extending maintenance intervals and maintaining consistent performance.

Reduced Thermal Stress

Optimized fin geometry distributes thermal stresses more evenly, reducing the risk of fin cracking and extending operational lifespan in cyclic duty applications.

Pressure Drop Optimization

Advanced serration patterns achieve optimal balance between heat transfer enhancement and flue gas pressure drop, minimizing fan power consumption.

Performance Comparison: Serrated vs. Conventional Finned Tubes

| Performance Metric | Serrated Finned Tubes | Solid Finned Tubes | Improvement Percentage |

|---|---|---|---|

| Heat Transfer Coefficient (W/m²K) | 85-120 | 60-85 | 35-45% |

| Fouling Resistance (m²K/W) | 0.0008-0.0012 | 0.0015-0.0025 | 40-60% reduction |

| Pressure Drop (Pa/m) | 80-150 | 50-100 | 40-60% increase (managed) |

| Maintenance Interval (months) | 24-36 | 12-18 | 80-100% extension |

| Overall Efficiency Gain | 8-12% | 5-8% | 3-5% absolute improvement |

Performance Data Analysis

Field studies across 45 power plants demonstrate that serrated finned tube economizers achieve average efficiency improvements of 8.7% compared to conventional designs, with payback periods typically under 18 months due to reduced fuel consumption and maintenance costs.

Serrated Finned Tube Economizer Applications in Modern Power Generation

With the continuous increase in generator unit capacity and declining coal quality in thermal power plants, higher performance requirements have been established for economizer systems. Serrated finned tube economizers have emerged as the preferred solution for demanding applications:

- Supercritical and ultra-supercritical boilers (600 MW and above)

- Waste heat recovery systems in process industries

- Biomass and waste-to-energy power plants

- Combined cycle power generation systems

- Cogeneration and district heating applications

- Marine propulsion and auxiliary power systems

- Petrochemical processing heaters

- Cement and glass manufacturing kilns

Serrated Finned Tube Economizer Design

The performance of serrated finned tube economizers is influenced by several critical factors that engineers must consider during design and specification:

Flue Gas Composition and Temperature Profile

Variations in fuel quality directly impact flue gas characteristics, requiring customized fin geometry and material selection to address potential corrosion and erosion concerns.

Flow Distribution and Velocity Optimization

Proper gas-side velocity (typically 8-12 m/s) must be maintained to balance heat transfer enhancement against erosion risk and pressure drop limitations.

Material Selection for Specific Operating Conditions

Advanced alloy selections based on temperature, pressure, and corrosion potential are critical for long-term reliability in aggressive flue gas environments.

Economic Impact

The implementation of serrated finned tube economizers delivers substantial economic benefits through multiple mechanisms:

| Benefit Category | Typical Value | Financial Impact |

|---|---|---|

| Fuel Efficiency Improvement | 2-4% | $150,000-$400,000 annually (600MW plant) |

| Maintenance Cost Reduction | 30-40% | $50,000-$120,000 annually |

| Forced Outage Reduction | 3-5 days/year | $300,000-$800,000 annually |

| Equipment Lifetime Extension | 25-40% | Capital expenditure deferral |

Economizer Development Trends

Ongoing research and development in serrated finned tube technology focuses on several key areas:

- Advanced computational fluid dynamics (CFD) modeling for optimized fin geometry

- Development of corrosion-resistant coatings for challenging fuel applications

- Integration with digital monitoring and predictive maintenance systems

- Hybrid designs combining serrated and other fin profiles for specific applications

- Materials innovation for higher temperature and pressure applications

The continuous evolution of serrated finned tube economizer technology ensures these components will remain at the forefront of heat recovery system design, delivering enhanced efficiency and reliability in an increasingly demanding power generation landscape.