Lord Fin Tube--H-fin tube economizer Profile

H-Fin Tube Economizer Overview:

China, being a coal-rich country, relies on coal as the primary fuel for thermal power plants according to its new energy policy. The objective is to minimize the use of low-grade coal while facing challenges such as imperfect coal supply and blending. Power plants utilizing coal as a medium encounter difficulties in maintaining continuous boiler performance, resulting in issues like wear, dust, slag, corrosion, and a reduction in overall coal combustion efficiency.

Challenges in Thermal Power Plants:

Based on the statistics from 1996, boiler accidents accounted for 56% of all power generation accidents in China, with tube blasting and leakage making up 66% of these accidents. Among the causes, coal dust accumulation was responsible for 38.6%. These accidents are not only linked to pipe and welding issues but are mainly attributed to problems such as ash, slag, high and low-temperature corrosion, wear, and vibration within the boiler.

Foreign Research and Development:

To address these issues, extensive theoretical research and practical exploration have been conducted abroad, leading to significant advancements in dealing with ash, slag, corrosion, wear, and vibration. Drawing inspiration from foreign technologies and considering Chinas specific conditions, the H-type economizer has been designed and developed.

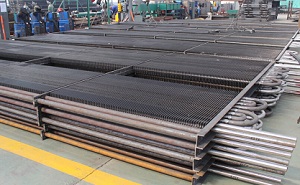

H-Type Fin Tube Economizer Features:

1. Fins Welded in Bare Pipe:

- Fins are welded into the bare pipe to replace the bare tube heating surfaces.

- The arrangement ensures the same diameter and length as the light tube 6~9 times.

2. Increased Heat Transfer Area:

- Offers a larger surface area for heat transfer, increasing the heat absorption capacity of coal.

- Achieves enhanced heat transfer and a higher heat transfer coefficient compared to bare tubes.

3. Enhanced Heat Transfer Coefficient:

- The increased heat transfer area contributes to improved heat transfer coefficients.

- The H-type fin and chamber enhance fluid turbulence, improving the fluid flow state for stronger heat transfer.

4. Compact Space Design:

- The economizer features a compact design, utilizing space efficiently.

- The space efficiency is estimated to be 50~60% of a wrongly arranged column of light tubes.

H-Fin Tube Economizer Conclusion:

The H-type fin tube economizer serves as an innovative solution to the challenges faced by coal-based thermal power plants in China. By incorporating advanced technologies and designs, it aims to improve heat transfer efficiency, reduce accidents, and optimize the utilization of coal resources in alignment with the countrys energy policies.