Products Description

What is HH-type finned tube/Double H finned tubes?

HH type finned tubes are also called rectangular finned tubes. HH type finned tubes is special H type finned tube, which have double tubes. The HH-shaped finned tube is to weld two steel sheets with a circular arc in the middle symmetrically with the light tube to form fins. The front of the fin is shaped like double "H", so it is called HH-type finned tube. HH-type finned tubes have great effects to recover the waste heat of exhaust gas from power station boilers, industrial boilers, industrial kilns, ship power plants, etc.

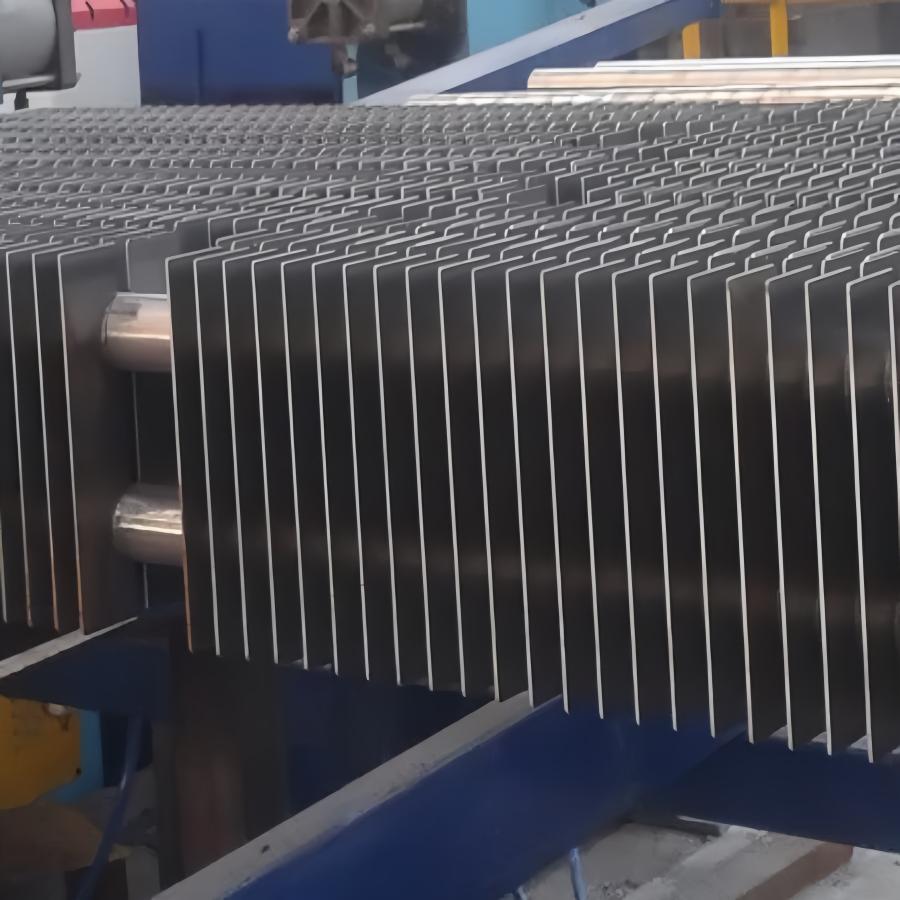

How to produce HH-type finned tubes/Double H finned tubes?

HH-type finned tubes is almost same production method. The fins formed by stamping and shearing of the steel plate are manually coded into the sheet automatic unloading hopper, and the feeding cylinder realizes automatic unloading. At the same time, Both steel pipes are transported to the welding position, and the horizontal pushing cylinder pushes the electrode clamping mechanism to realize automatic welding. The electrode clamping mechanism is the key part of the welding machine, and the electrodes on both sides are equipped with material receiving and pneumatic positioning mechanisms. And it is pushed centripetally by the push cylinder, and the fins automatically enter the welding position, clamping and welding, and realize the welding of the fins on both sides and the steel pipes. After the welding is completed, the clamping is released, the finned tube is manually removed, and the steel tube moves forward. The parallel automatic welding of steel pipes and fins can well meet the quality and efficiency requirements of finned tube welding.

HH-type finned tube/Double H finned tubes material and size:

|

Base Tube O.D (mm) |

Base Tube Thickness (mm) |

Fin Height (mm) |

Fin Thickness (mm) |

Fin Pitch (mm) |

||

|

25.4 mm ~50.8 mm |

2.5 mm ~5.0 mm |

50 mm ~200 mm |

0.5 mm ~3.0 mm |

5 mm ~ 25.4 mm |

||

|

Base Tube Material |

Fin Material |

Tube Length (Mtr) |

||||

|

Carbon Steel ,Alloy Steel ,Stainless Steel, ND steel |

Carbon Steel ,Alloy Steel ,Stainless Steel, ND steel |

≤ 15Mtrs |

||||

HH-type finned tube/Double H finned tubes product advantages:

1. The new finned tube welding process is adopted, and the contact of the fin welding part adopts multiple zigzag shapes, so that the fin welding is firm, the welding shape is uniform, the surface is smooth, there is no slag inclusion, pore welding, and the penetration rate reaches 97%.

2. The welding position adopts multiple zigzag methods, which is equivalent to reducing the local stiffness of the finned tube, thereby reducing the amount of compressive plastic deformation generated during the welding process, reducing the longitudinal residual tensile stress near the weld, and also greatly The residual compressive stress of the sheet away from the weld is reduced, so the wave deformation of the sheet is significantly reduced.

3. The penetration rate is 97%, the surface of the weld seam is uniform and smooth without welding bumps, and the expansion of the heating surface can increase the heat transfer coefficient.

4. The extended heating surface unit has a self-cleaning function, which can slow down the deposition, blockage and wear of soot on the heating surface, especially slowing down the wear can ensure a reasonable service life of the heating surface.

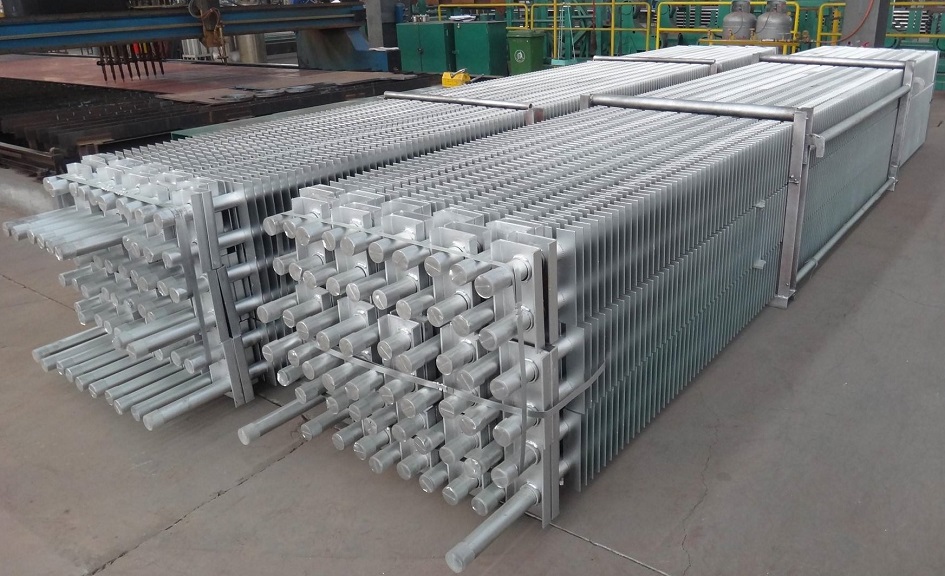

Application of HH-type finned tube/Double H finned tubes:

HH-shaped finned tubes are designed to recover exhaust heat from power plant boilers, industrial boilers, industrial kilns, ship power plants, etc., and effectively improve fuel utilization. The enhanced heat exchange elements are arranged at the tail of the system flue.

Square fin tube, H fin tube, rectangular fin tubes, double H fin tubes

Square Fins are welded on 1 steel base tubes. We call it H Fin Type Tubing. Square Fin Tube with 90 Degree Bends, Rectangular Finned Tubes with 90 Degree Bends

We offer rectangular finned tubes as single or twin tubes in addition to the proven helical or spiral fin design. These rectangular finned tubes are particularly good suited for dust laden exhaust gases that tend to scaling, e.g. for economizers in coal or oil fired units. Straight tube arrangements favour a decrease of scaling as well as easier cleaning and maintenance and will lower the resistance coefficient.

We are designing and manufacturing fin tube modules, economizers/heat exchangers and the suitable heating surface cleaning systems according to your requirements.

HH Finned Tube with Bend

Rectangular Single or Twin Finned Tubes

H fin tube known as square fin tube, there are two types of H fin tubes, one type with single tube, normal called square fin tube, the other with Double tube, normal called rectangular fin tubes. and also manufactured as per customers requirements. Due to rectangular shapes, which can offer large surface area compared to the Spiral Finned tubes. Due to larger surface area available, these finned tubes are used mostly in Air Heating application to reduce the overall size of the equipment.

H Finned Tube

H fin tube is a kind of boiler parts, which has two steel circular welded on base tubes to form fins positive shape much like letter "H", so called H-fin tube. H-economizer widely used in utility boilers, industrial boilers, marine power, such as the tail of heat exchanger components.

H Finned Tube Principle:

H Finned Tube economizer has two rectangular fins, similar to a square, its edge length for the fluorescent tubes of 2-fold, an expansion of the heating surface.

Rectangular Fins are welded on 2 steel base tubes. We call it HH or Doule H Fin Type Tubing.

HH Finned Tube economizer flash resistance welding processes used the welding seam after the high rate of fusion, weld tensile strength, and have good thermal conductivity. H-economizer can also manufacture dual tube "double H" type fin tubes, its rigid structure, and can be applied to a longer tube row occasion.

Max. Working Temperature: 300 °C

Atmospheric Corrosion Resistance: OK

Mechanical Resistance: Good

Fin Material: Copper, Aluminum, carbon steel, stainless steel

Base Tube materials: Any material available, such as Carbon steel Tube, A179, A192, A210, stainless tube A269/A213 T5 T11 T22 304 316

Rectangular Finned Tubes

Single pipe square finned tubes and twin pipe rectangular finned tubes are also manufactured as per customers’ requirements. These are particularly suitable for dust laden exhaust gases, e.g. for economizers in coal and oil fired units or waste incinerators.

Tubo de aleta cuadrado, tubo de aleta H, tubos de aleta rectangular, tubos de aleta doble H

Las aletas cuadradas están soldadas en 1 tubo base de acero. Lo llamamos tubería tipo H Fin. Tubo de aleta cuadrado con curvas de 90 grados, tubos aleteados rectangulares con curvas de 90 grados

Ofrecemos tubos aleteados rectangulares como tubos simples o gemelos, además del diseño probado de aleta helicoidal o espiral. Estos tubos con aletas rectangulares son particularmente adecuados para gases de escape cargados de polvo que tienden a escalar, p. para economizadores en unidades de carbón o petróleo. Las disposiciones de los tubos rectos favorecen una disminución de la incrustación, así como una limpieza y mantenimiento más fáciles, y reducirán el coeficiente de resistencia.

Estamos diseñando y fabricando módulos de tubos de aletas, economizadores / intercambiadores de calor y los sistemas de limpieza de superficies de calefacción adecuados de acuerdo con sus requisitos.

Tubo con aletas HH con curva

Tubos rectangulares de aletas simples o gemelas

Tubo de aleta H conocido como tubo de aleta cuadrada, hay dos tipos de tubos de aleta H, un tipo con un solo tubo, normal llamado tubo de aleta cuadrada, el otro con tubo doble, normal llamado tubo de aleta rectangular. y también fabricado según los requisitos de los clientes. Debido a las formas rectangulares, que pueden ofrecer una gran superficie en comparación con los tubos con aletas espirales. Debido a la mayor superficie disponible, estos tubos con aletas se utilizan principalmente en la aplicación de calentamiento de aire para reducir el tamaño general del equipo.

Tubo con aletas H

El tubo de aleta H es un tipo de piezas de caldera, que tiene dos tubos circulares de acero soldados en tubos base para formar aletas de forma positiva muy similar a la letra "H", llamada tubo de aleta H. H-economizer ampliamente utilizado en calderas de servicios públicos, calderas industriales, energía marina, como la cola de los componentes del intercambiador de calor.

Principio:

El economizador de tubo con aletas H tiene dos aletas rectangulares, similares a un cuadrado, su longitud de borde para los tubos fluorescentes de 2 veces, una expansión de la superficie de calentamiento.

Las aletas rectangulares están soldadas en 2 tubos base de acero. Lo llamamos tubería tipo HH o Doule H Fin.

Los procesos de soldadura de resistencia al flash del economizador de tubo con aletas HH utilizaron la costura de soldadura después de la alta velocidad de fusión, la resistencia a la tracción de la soldadura y tienen una buena conductividad térmica. H-economizer también puede fabricar tubos de aletas de doble tubo tipo "doble H", su estructura rígida, y puede aplicarse a una fila de tubos más larga.

Max. Temperatura de trabajo: 300 ° C

Resistencia a la corrosión atmosférica: OK

Resistencia Mecánica: Buena

Material de la aleta: cobre, aluminio, acero al carbono, acero inoxidable

Materiales del tubo base: cualquier material disponible, como tubo de acero al carbono, A179, A192, A210, tubo inoxidable A269 / A213 T5 T11 T22 304 316

Tubos Rectangulares Aletados

Los tubos con aletas cuadradas de tubo simple y los tubos con aletas rectangulares de tubo doble también se fabrican según los requisitos de los clientes. Estos son particularmente adecuados para gases de escape cargados de polvo, p. para economizadores en unidades de carbón y petróleo o incineradores de residuos.

Finned Tube----Square fin tube, H fin tube, rectangular fin tubes, double H fin tubes

Square Fins are welded on 1 steel base tubes. We call it H Fin Type Tubing. Square Fin Tube with 90 Degree Bends, Rectangular Finned Tubes

We offer rectangular finned tubes as single or twin tubes in addition to the proven helical or spiral fin design. These rectangular finned tubes are particularly good suited for dust laden exhaust gases that tend to scaling, e.g. for economizers in coal or oil fired units. Straight tube arrangements favour a decrease of scaling as well as easier cleaning and maintenance and will lower the resistance coefficient.

We are designing and manufacturing fin tube modules, economizers/heat exchangers and the suitable heating surface cleaning systems according to your requirements.

H fin tube known as square fin tube, there are two types of H fin tubes, one type with single tube, normal called square fin tube, the other with Double tube, normal called rectangular fin tubes. and also manufactured as per customers requirements. Due to rectangular shapes, which can offer large surface area compared to the Spiral Finned tubes. Due to larger surface area available, these finned tubes are used mostly in Air Heating application to reduce the overall size of the equipment.

H fin tube is a kind of boiler parts, which has two steel circular welded on base tubes to form fins positive shape much like letter "H", so called H-fin tube. H-economizer widely used in utility boilers, industrial boilers, marine power, such as the tail of heat exchanger components.

Principle:

H Finned Tube economizer has two rectangular fins, similar to a square, its edge length for the fluorescent tubes of 2-fold, an expansion of the heating surface.

Rectangular Fins are welded on 2 steel base tubes. We call it HH or Doule H Fin Type Tubing.

HH Finned Tube economizer flash resistance welding processes used the welding seam after the high rate of fusion, weld tensile strength, and have good thermal conductivity. H-economizer can also manufacture dual tube "double H" type fin tubes, its rigid structure, and can be applied to a longer tube row occasion.

Max. Working Temperature: 300 °C

Atmospheric Corrosion Resistance: OK

Mechanical Resistance: Good

Fin Material: Copper, Aluminum, carbon steel, stainless steel

Base Tube materials: Any material available, such as Carbon steel Tube, A179, A192, A210, stainless tube A269/A213 T5 T11 T22 304 316

Rectangular Finned Tubes

Single pipe square finned tubes and twin pipe rectangular finned tubes are also manufactured as per customers’ requirements. These are particularly suitable for dust laden exhaust gases, e.g. for economizers in coal and oil fired units or waste incinerators.

In order to forward you a promt offer we would be pleased to receive you detailed enquiry including:

• Base tube material

• Base tube size (OD x WT x Length)

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

• Finned Tube Quantity

(Additional fabrication, such as bend or weld the tubes into tubeplate or assembly)

Keywords: Fin tubes, Finned tube, Finned Pipe Helical Finned Tubes, Solid fin tubes,Serrated finned tube, Helical Serrated Finned Tubes, Square Fin Tube,Rectangular Double H welding Fin Tube,Tubos Aletados