Lord Fin Tube--H type fin tube defination

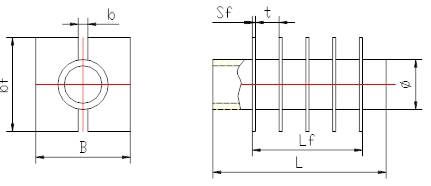

Technical Summary: H-type fin tubes (also called H-fin tubes) are specialized heat transfer components featuring parallel fin plates attached to a base tube, creating an "H" shaped cross-section. This design significantly enhances heat transfer efficiency in various industrial applications.

What Are H-Type Fin Tubes?

H-type fin tubes represent an advanced heat transfer technology where parallel fin plates are welded or embedded onto the outer surface of a base tube. When viewed from the end, the distinctive "H" shape is clearly visible, giving these tubes their name. The design creates multiple channels between fins that optimize fluid flow and heat exchange.

The primary function of H-type fin tubes is to maximize surface area for heat transfer while maintaining structural integrity. This makes them particularly valuable in applications where space constraints exist but high thermal efficiency is required.

Technical Specifications and Design Parameters

| Parameter | Standard Range | Material Options | Performance Impact |

|---|---|---|---|

| Base Tube Diameter | 25mm - 100mm | Carbon Steel, Stainless Steel | Determines pressure capacity |

| Fin Height | 12mm - 25mm | Aluminum, Copper | Affects surface area increase |

| Fin Thickness | 1.0mm - 2.5mm | Carbon Steel, Stainless Steel | Impacts durability and heat transfer |

| Fin Pitch | 4mm - 12mm | N/A | Controls flow resistance |

| Surface Area Ratio | 7:1 - 22:1 | N/A | Measures efficiency improvement |

Performance Advantages of H-Type Fin Tubes

Enhanced Heat Transfer

The H-shape creates multiple channels that disrupt boundary layers and promote turbulent flow, significantly improving heat transfer coefficients compared to smooth tubes.

Reduced Fouling

The straight gas flow path minimizes ash deposition and fouling, making H-type fins ideal for applications with particulate matter in the fluid stream.

Structural Integrity

The welded fin construction provides excellent mechanical strength and vibration resistance, ensuring long service life even in demanding conditions.

Compact Design

High surface area to volume ratio allows for more compact heat exchanger designs, reducing overall equipment size and weight.

Comparison with Other Fin Tube Types

| Feature | H-Type Fin Tube | L-Type Fin Tube | G-Type Fin Tube | Extruded Fin Tube |

|---|---|---|---|---|

| Fin Attachment | Welded (Footed) | Wrapped | Embedded | Integral |

| Thermal Resistance | Low | Medium | Low-Medium | Very Low |

| Fouling Resistance | Excellent | Good | Very Good | Fair |

| Max Operating Temperature | 400°C | 250°C | 350°C | 300°C |

| Relative Cost | Medium-High | Low | Medium | High |

H-Type Fin Tube Industrial Applications

H-type fin tubes are utilized across multiple industries where efficient heat transfer is critical:

- Power Generation: Economizers, air preheaters, and condensers in thermal power plants

- Petrochemical: Process heaters, waste heat recovery units, and reforming furnaces

- HVAC Systems: Large-scale air conditioning and heat recovery ventilators

- Marine Applications: Shipboard heat exchangers and engine cooling systems

- Waste Incineration: Boilers and heat recovery in waste-to-energy plants

- Chemical Processing: Reactors, distillation columns, and process heaters

- Refining Industry: Crude heaters, catalytic reformers, and hydrotreater charge heaters

- Metallurgical: Heat recovery from furnace exhaust gases

Material Selection Guide

The choice of materials for H-type fin tubes depends on the operating environment and performance requirements:

| Application Environment | Recommended Base Tube Material | Recommended Fin Material | Temperature Limit | Corrosion Resistance |

|---|---|---|---|---|

| General Purpose / Air | Carbon Steel | Carbon Steel | 400°C | Fair |

| Corrosive Atmosphere | Stainless Steel 304/316 | Stainless Steel 304/316 | 450°C | Excellent |

| High Temperature | Stainless Steel 321/310 | Stainless Steel 321/310 | 650°C | Good |

| Marine / Coastal | Copper-Nickel | Aluminum | 250°C | Very Good |

| Maximum Heat Transfer | Carbon Steel | Copper/Aluminum | 260°C | Fair |

H-Type Fin Tube Design

Thermal Performance Optimization

To maximize the efficiency of H-type fin tubes, engineers should consider fin density, height, and thickness in relation to the specific application. Higher fin density increases surface area but may lead to increased pressure drop and fouling in dirty gas streams.

Mechanical Design Factors

The footed design of H-type fins provides superior mechanical stability compared to L-type fins. This makes them suitable for applications with vibration or where thermal cycling occurs. Proper welding techniques are critical to prevent fin detachment under operational stresses.

Maintenance and Cleaning

The straight gas path between fins in H-type designs facilitates easier cleaning compared to spirally-wound fins. Soot blowers and water washing systems are more effective, reducing maintenance downtime in applications with fouling potential.

Industry Insight: H-type fin tubes typically provide 15-25% better heat transfer performance compared to L-type fins in similar applications, with significantly improved resistance to fouling and mechanical damage. This makes them the preferred choice for demanding industrial applications where reliability and efficiency are paramount.

As heat transfer technology continues to evolve, H-type fin tubes remain a robust solution for industrial heat exchange applications, offering an optimal balance of performance, durability, and maintenance requirements.