Lord Fin Tube--Introduction of High Flux tubes

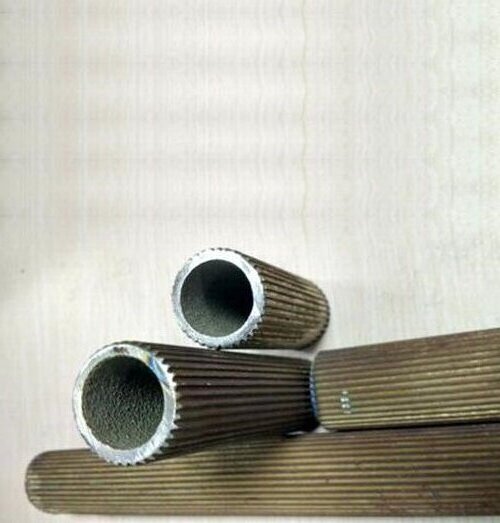

What are high-flux tubes?

High-flux tubes are typically associated with heat exchangers, particularly in the context of nuclear reactors and other high-temperature applications. A heat exchanger is a device designed to transfer thermal energy between two or more fluids, while keeping them physically separated. The term "high-flux tubes" refers to the tubes within the heat exchanger that are responsible for the efficient transfer of heat between the fluids.

The term "high-flux" indicates that these tubes are designed to handle a significant amount of heat transfer. In nuclear reactors, for example, high-flux tubes are used to carry extremely hot coolant (often a liquid metal like sodium or lead) away from the reactor core, where nuclear reactions generate a substantial amount of heat. The high-flux tubes are designed to withstand high temperatures, high pressures, and potentially harsh radiation environments.

The design of high-flux tubes takes into account factors such as heat transfer efficiency, material properties, thermal stress, corrosion resistance, and structural integrity. They are often made from specialized materials that can handle the extreme conditions while maintaining their mechanical and thermal properties over time.

High-flux tubes play a crucial role in high-temperature heat exchangers, especially in applications like nuclear reactors, where they facilitate the transfer of heat from a high-temperature source to a heat sink, all while maintaining the safety and stability of the overall system.

High-flux tubes Applications:

1. Nuclear Reactors: High-flux tubes are commonly used in nuclear reactors for both power generation and research purposes. In nuclear power plants, they are often part of the reactors primary heat exchanger system, where they transfer heat from the reactor core to a secondary loop that drives a turbine and generates electricity. These tubes are exposed to high temperatures due to the nuclear reactions taking place in the core.

2. Solar Thermal Power: High-flux tubes are used in solar thermal power plants, where they capture and concentrate sunlight onto a heat exchanger to generate steam and produce electricity. The concentrated solar energy can cause extreme temperatures, and the high-flux tubes need to withstand these conditions while efficiently transferring heat to the working fluid.

3. Chemical Processes: In high-temperature chemical processes, such as petroleum refining or chemical manufacturing, high-flux tubes can be used to facilitate heat exchange between reactive substances. These tubes are often designed to withstand corrosive environments and high thermal stresses.

4. Aerospace and Propulsion: High-flux tubes find applications in aerospace engineering, particularly in the cooling systems of high-performance engines and propulsion systems. They help manage the extreme heat generated during combustion and ensure the engine components remain within their operational limits.

High-flux tubes Design Considerations:

1. Material Selection: High-flux tubes are typically made from materials with excellent heat transfer properties, high melting points, and resistance to corrosion and thermal fatigue. Materials like stainless steel, nickel-based alloys, and refractory metals are commonly used.

2. Heat Transfer Efficiency: The design of high-flux tubes focuses on maximizing the heat transfer coefficient, which determines how effectively heat is transferred from the hot fluid to the tube wall and then to the cold fluid.

3. Structural Integrity: The tubes must be able to withstand the thermal stresses and pressure differentials they experience. The design must consider factors such as mechanical stability, creep resistance, and fatigue life.

4. Corrosion Resistance: In aggressive environments, such as those with corrosive fluids or high-temperature oxidation, the tubes material must resist degradation over time.

5. Coolant Flow: Effective coolant flow inside the tubes is essential for efficient heat transfer. Proper design ensures that flow velocities and turbulence are conducive to heat exchange.

6. Radiation Considerations: In nuclear reactor applications, radiation from the reactor core can affect the material properties of the tubes over time. Designing tubes to withstand radiation-induced damage is critical.

7. Thermal Expansion: High temperatures can cause materials to expand, which must be accounted for in the design to prevent structural failures.

High-flux tubes play a vital role in various industries where high-temperature heat exchange is essential. Their design and engineering are complex, requiring a careful balance of material selection, thermal considerations, mechanical properties, and efficiency to ensure safe and effective operation in demanding environments.