Lord Fin Tube--ASTM A 179 L type finned tube

ASTM A179 L Type Finned Tubes

Superior Heat Transfer Solution for Industrial Applications

Why Choose ASTM A179 L Type Finned Tubes?

ASTM A179 L type finned tubes represent an advanced heat transfer solution designed for efficiency and durability in demanding industrial environments. These specialized tubes combine the strength of low-carbon steel with the superior thermal conductivity of aluminum fins, creating an optimal balance for heat exchange applications.

Key Advantage: The L-foot design provides maximum contact between fin and tube, ensuring excellent heat transfer while maintaining mechanical stability under thermal cycling conditions.

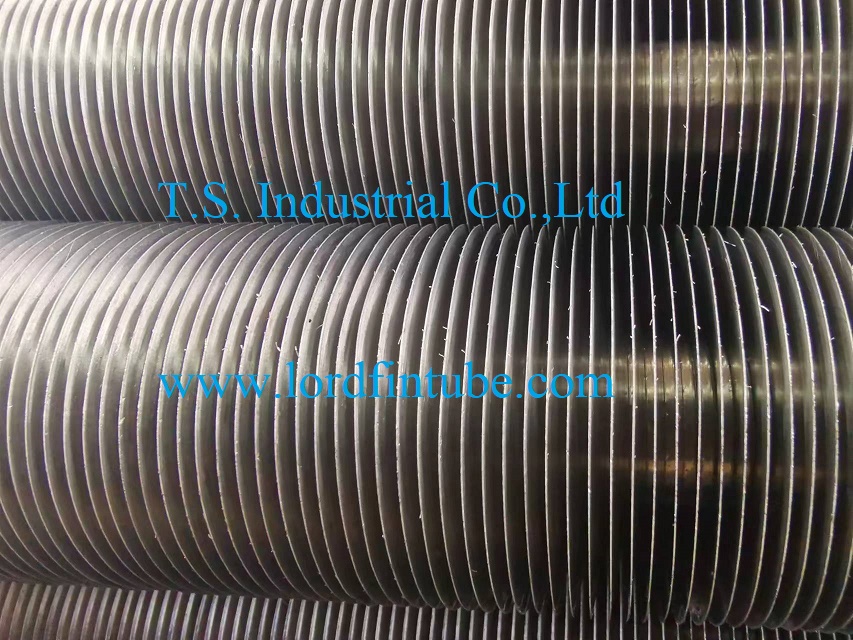

L-Foot finned aluminum tubes are manufactured using a thin aluminum fin strip that is helically wound around the circumference of an ASTM A179 base tube. The unique feature is the L-shaped foot (1/16" wide) formed on one side of the fin strip, which gives this fin type its name.

During the winding process, the fin strip is tensioned to forcefully seat the L-foot on the tubes outer surface, creating a tight mechanical bond without the need for additional adhesives or welding in many applications. The standard fin spacing is typically 10 fins per inch, though this can be customized based on specific thermal performance requirements.

Technical Specifications

The following table outlines typical specifications for ASTM A179 L type finned tubes based on common industry inquiries:

| ASTM A179 L Type Fin Tubes - Standard Specifications | ||||

| Base Tube Material | Fin Material | Tube Length (mm) | Fin Length (mm) | Fin Tube Quantity (Pc) |

|---|---|---|---|---|

| ASTM A179 | Aluminum | 9144 | 9024 | 200 |

| Base Tube O.D (mm) | Base Tube Thickness (mm) | Fin Height (mm) | Fin Thickness (mm) | Fin Pitch (mm) |

| 25.4 | 2.11 | 15.88 | 0.4 | 2.54 |

| Material Note: ASTM A179 is the standard specification for seamless cold-drawn low-carbon steel heat-exchanger and condenser tubes, known for excellent thermal conductivity and formability. | ||||

Key Specifications Summary

- Base Tube: ASTM A179 seamless cold-drawn low-carbon steel

- Fin Material: High-grade aluminum for optimal heat transfer

- Fin Design: L-foot configuration for secure attachment

- Temperature Range: Suitable for operations from -40°F to 500°F (-40°C to 260°C)

- Pressure Rating: Varies based on tube dimensions and application requirements

Industrial Applications

These versatile finned tubes serve critical functions across numerous industries:

Petroleum & Chemical

Heat exchange in refinery operations and chemical processing plants

Power Generation

Steam turbine exhaust condensing in fossil and nuclear power plants

Natural Gas Treatment

Cooling and condensation applications in gas processing facilities

Steel Industry

Blast furnace and converter cooling systems

HVAC Systems

Air conditioning applications using various refrigerants

Waste Management

Heat recovery in household refuse incineration plants

Performance Advantages

ASTM A179 L type finned tubes offer several distinct benefits:

- Enhanced Heat Transfer: The aluminum fins significantly increase the surface area for improved thermal efficiency

- Corrosion Resistance: Aluminum fins provide excellent resistance to atmospheric corrosion

- Mechanical Stability: The L-foot design maintains fin contact under thermal cycling conditions

- Cost-Effectiveness: Aluminum fins on steel tubes provide performance at a lower cost than all-copper alternatives

- Customizable Configuration: Available in various fin densities, heights, and lengths to meet specific application requirements

Did you know? L-type finned tubes can increase heat transfer efficiency by up to 300% compared to bare tubes, making them an excellent choice for applications where space is limited but high heat transfer rates are required.

ASTM A179 L type finned tube - Note the secure attachment of the L-foot aluminum fins to the steel base tube

Selection Considerations

When specifying ASTM A179 L type finned tubes, consider these factors:

- Operating temperature ranges and thermal cycling conditions

- Chemical compatibility with process fluids and environment

- Required heat transfer efficiency and pressure drop limitations

- Space constraints and overall heat exchanger dimensions

- Maintenance requirements and accessibility for cleaning

For specific application engineering support, consult with Lord Fin Tubes technical team to ensure optimal selection for your project requirements.

ASTM A179 L type finned tubes

ASTM A179 L type finned tubes offer an efficient, reliable solution for heat transfer applications across multiple industries. Their unique construction provides an optimal balance between thermal performance, mechanical durability, and cost-effectiveness. Whether for new installations or replacement applications, these finned tubes deliver long-term performance in demanding operating conditions.

As a leading manufacturer of heat exchange components, Lord Fin Tube provides high-quality ASTM A179 L type finned tubes tailored to meet specific customer requirements and application challenges.

Expert Tip: Regular inspection and maintenance of finned tube bundles can extend service life by up to 30%. Consider implementing a preventive maintenance program to maximize the longevity of your heat exchange equipment.