Heat Exchanger Tube as per SA213-TP304

Heat Exchanger Tube as per SA213-TP304 Introduction:

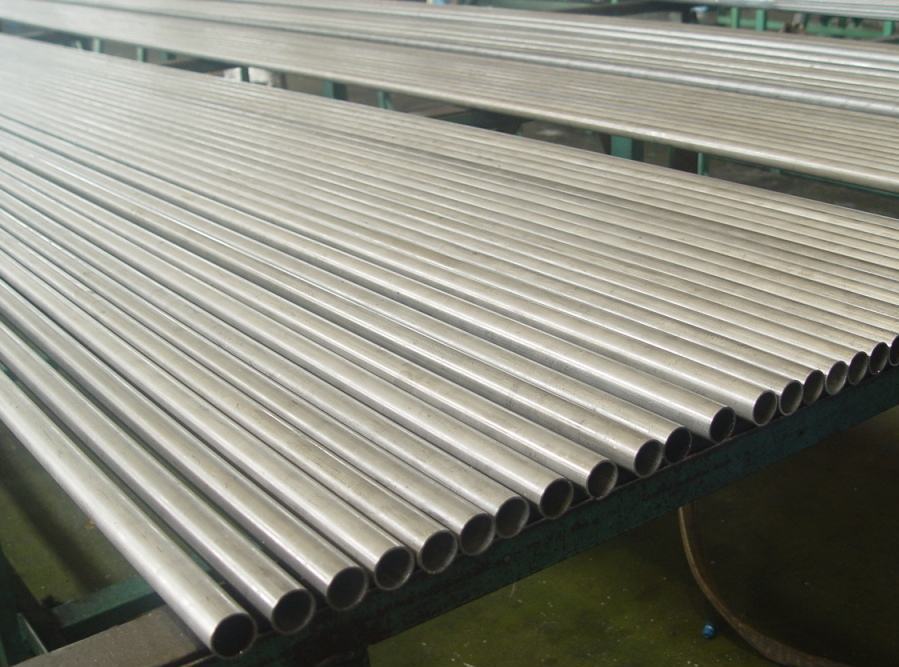

The designation "Heat exchanger tube SA213-TP304" refers to tubes manufactured in strict accordance with the ASME SA213 standard, utilizing TP304 grade stainless steel. These tubes are purpose-built for facilitating efficient heat transfer within heat exchangers, crucial components in various industrial processes.

Heat Exchanger Tube as per SA213-TP304 Material Composition:

ASME SA213 TP304 represents a stainless steel grade specifically engineered for standard heat exchanger or high-pressure tube applications. Composed predominantly of chromium and nickel, this alloy offers exceptional resistance to corrosion and oxidation, ensuring longevity and reliability in diverse operating conditions.

|

ASME SA213-TP304 Chemical Composition (W.T.%) |

||||||

|

Elements |

C |

Mn |

Si |

P |

S |

Cr |

|

Requirements |

≦0.030 |

≦2.00 |

≦1.00 |

≦0.045 |

≦0.030 |

18.00-20.00 |

|

Elements |

Ni |

Mo |

Ti |

N |

|

|

|

Requirements |

8.00-12.00 |

― |

― |

0.11 |

|

|

Heat Exchanger Tube as per SA213-TP304 Standard Specifications:

Aligned with ASTM A213/ASME SA213 standards, these tubes adhere to stringent specifications for seamless ferritic and austenitic alloy-steel tubes. Designed primarily for deployment in boilers, superheaters, and heat exchangers, they meet rigorous industry standards for performance and durability.

Heat Exchanger Tube as per SA213-TP304 Heat Treatment:

According to SA-213/SA-213M guidelines, all austenitic tubes undergo a meticulous heat treatment process. This involves heating the material to a minimum temperature of 1040°C, followed by rapid quenching in water or an equivalent cooling medium. This treatment enhances the materials mechanical properties and structural integrity.

Heat Exchanger Tube as per SA213-TP304 Surface Quality:

The surface of Heat exchanger tube SA213-TP304 undergoes rigorous inspection to ensure impeccable quality. Defects such as scale, cracks, bubbles, overlaps, folds, and inclusions are meticulously avoided, as they can compromise the tubes performance and longevity in service.

Heat Exchanger Tube as per SA213-TP304 Mechanical Properties Testing:

Mechanical properties are thoroughly evaluated through a battery of tests. Tension tensile tests are conducted on specimens from each lot, with particular attention paid to ensuring representative sampling. Additionally, flattening and flaring tests are performed on finished tubes to assess their ductility and formability.

|

ASME SA213-TP304 Mechanical Properties |

|||||

|

Test Items |

Rp0.2 |

Rm |

A50mm |

Z (%) |

Hardness |

|

Y.S.(MPa) |

T.S.(MPa) |

EL.(%) |

Reduction of Area |

||

|

Requirements |

≧170 |

≧485 |

≧35 |

― |

HRB≤90 |

Heat Exchanger Tube as per SA213-TP304 Quality Assurance Testing:

Each tube undergoes nondestructive electric or hydrostatic testing to verify its quality and integrity. These tests, which may reference SA-1016/SA-1016M standards, are essential in identifying any potential defects or weaknesses that could compromise the tubes performance in service.