What is laser welded finned tube?

What is laser welded finned tube?

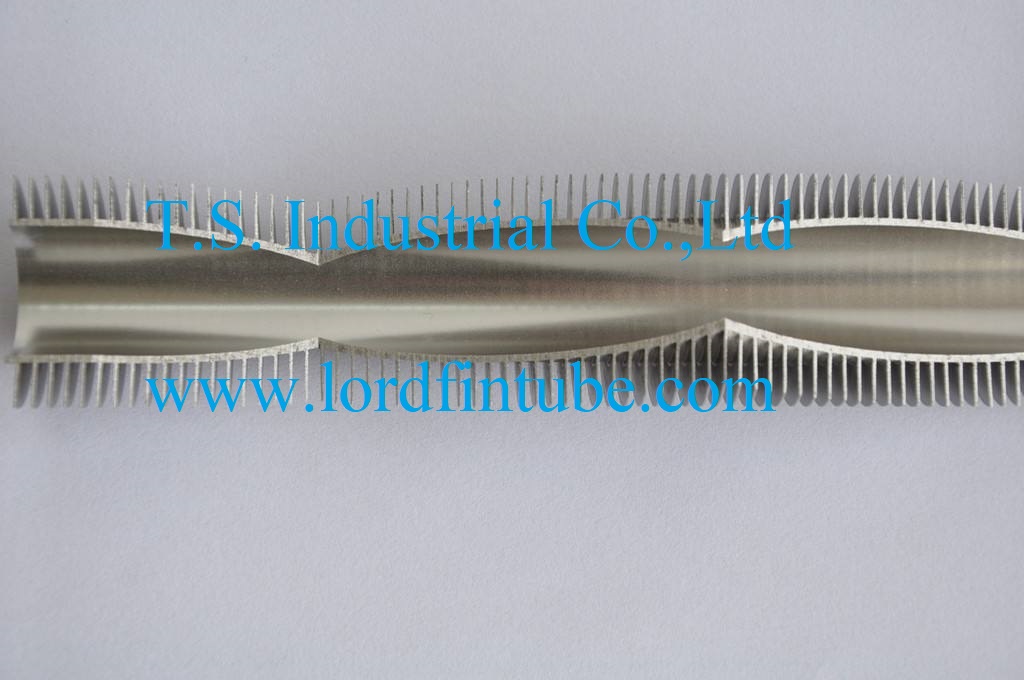

Laser welding of finned tubes adopts the laser welding process, which can weld the thin wall thickness tubes with thinner fins and denser fin pitch. The thinner thickness tubes and denser fins can improve the heat transfer efficiency. Good welding penetration rate and resistance to being pulled off are the basis of good service proformanace.

Why choose laser welded finned tubes?

1. Laser welding of finned tubes can realize welding between different metals, which can achieve good heat transfer efficiency for customers under different working conditions. Thin wall thickness is also one of the ways to save costs.

1. Laser welding of finned tubes can realize welding between different metals, which can achieve good heat transfer efficiency for customers under different working conditions. Thin wall thickness is also one of the ways to save costs.

2. The process of laser welding finned tubes is stable and the price is good, which provides support for product innovation of energy enterprises and opportunities for enterprise development. Laser welded finned tubes have higher heat transfer performance and lower material cost than high-frequency welded finned tubes, which will become the market development trend.

3. Laser welded finned tube is easy for deeper processing, and can directly coil and bend pipes.

4. Laser welded finned tube welding heat affected zone is small and the metallographic change is small, which makes it possible to process small diameter finned tubes.

5. Laser welded finned tube thickness of base tube can be 0.8-1.5 mm, and the thickness of fin can be 0.3-1 mm, which greatly saves the material cost compared with other processes.

Laser welded finned tubes dimensions and parameters

|

Tube OD(mm) |

Tube Thk (mm) |

Fin Pitch (mm) |

Fin Height (mm) |

Fin Thk (mm) |

|

Φ10 |

1.2-2 |

2-3.5 |

<5 |

0.3-1 |

|

Φ12 |

<6 |

|||

|

Φ16 |

<8 |

|||

|

Φ19 |

>1.0 |

2-5 |

<9 |

0.5-1 |

|

Φ22 |

>1.2 |

2-5 |

<11 |

|

|

Φ25 |

>1.3 |

2-6 |

<12.5 |

|

|

Φ28 |

>1.5 |

2-8 |

<14 |

0.8-1.2 |

|

Φ32 |

>1.5 |

2-8 |

<16 |

|

|

Φ38 |

>1.8 |

2-10 |

<19 |

|

|

Φ45 |

>2 |

2-10 |

<23 |

What material can be laser weld as finned tubes?

Material name: stainless steel+stainless steel, stainless steel+carbon steel, stainless steel+copper, carbon steel+carbon steel, carbon steel+copper, copper+copper

Laser welded finned tubes Supply capacity

4 sets of laser welding finned tube machines with daily production capacity of 2000m