Lord Fin Tube-Heat conduction process of laser welding fin tube

Laser welding fin tube is a process that involves the use of a laser beam to melt and fuse metal components. During the welding process, heat is generated at the point where the laser beam is focused, which causes the metal to melt and solidify as it cools.

Heat conduction is an important aspect of the laser welding process, as it determines the quality of the weld and the efficiency of the welding operation. Heat conduction occurs in three main stages:

1. Heat Absorption: The laser beam is absorbed by the surface of the metal, which causes it to heat up and melt. The heat absorption rate depends on the material being welded and the intensity of the laser beam.

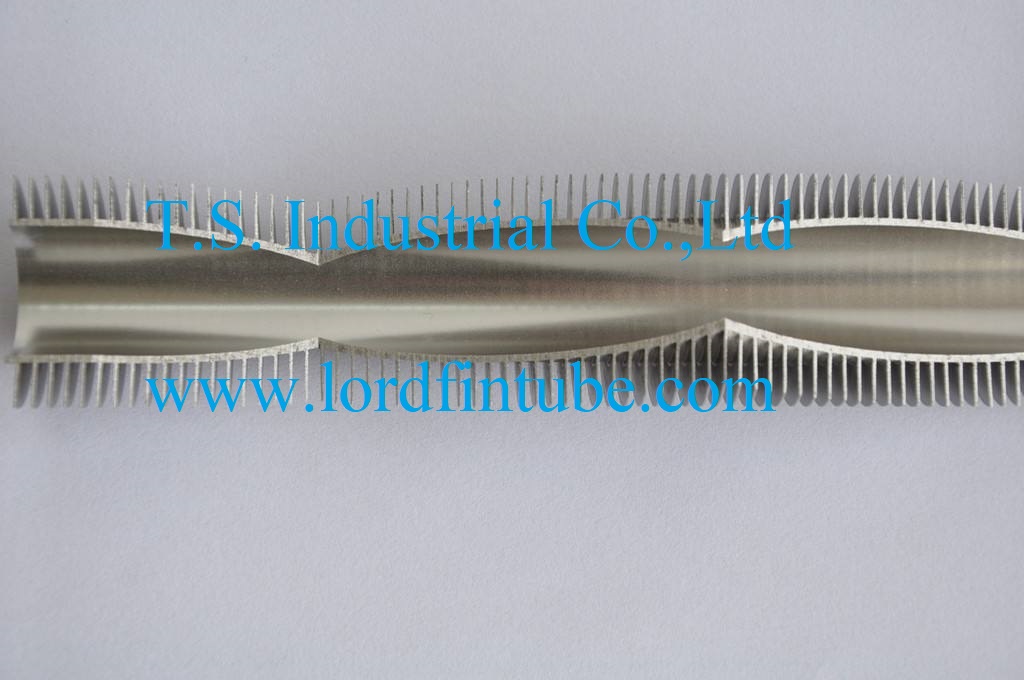

2. Heat Transfer: Once the metal has absorbed the laser beam, the heat begins to transfer through the material. This is where the fin tube design comes into play, as the fins increase the surface area of the tube and allow for better heat transfer.

3. Heat Dissipation: As the heat travels through the metal, it begins to dissipate into the surrounding environment. This can cause a temperature gradient within the material, which can affect the quality of the weld.

To ensure a successful laser welding process, it is important to control the heat conduction process. This can be achieved through careful selection of the laser parameters, such as the intensity and duration of the laser beam. Additionally, proper cooling techniques can be used to dissipate the heat and prevent overheating of the material.