What is low finned cooler tube?

Low Finned Cooler Tube

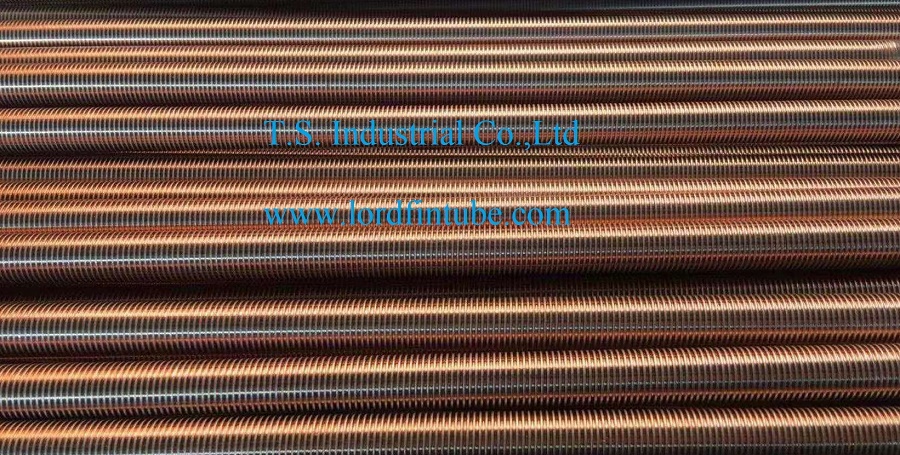

Low finned cooler tubes represent a specialized heat transfer technology designed to maximize efficiency in thermal management systems. These precision-engineered components feature external fins with lower height profiles compared to standard finned tubes, creating an optimal balance between surface area enhancement and structural integrity for diverse industrial applications.

Low Finned Cooler Tube Technology

Low finned cooler tubes are sophisticated heat exchanger components engineered with external fins that typically range from 0.90mm to 2.50mm in height. This strategic fin design significantly increases the external surface area of the tube—often by 2.5 to 3 times compared to plain tubes—while maintaining a compact profile that facilitates efficient heat transfer in space-constrained applications.

Unlike conventional high-fin tubes, the low-profile fin design minimizes fouling tendencies while providing substantial heat transfer enhancement. This makes low finned tubes particularly valuable in applications where maintenance accessibility is limited or where fluid streams contain particulate matter that could accumulate on more pronounced fin structures.

Enhanced Heat Transfer

The extended surface area created by the fins dramatically improves heat exchange efficiency, allowing for more compact heat exchanger designs without sacrificing performance.

Space Optimization

Low finned tubes deliver superior heat transfer per unit volume, making them ideal for applications where physical space is at a premium.

Reduced Fouling

The lower fin profile minimizes debris accumulation and simplifies cleaning procedures, reducing maintenance requirements and downtime.

Material Specifications and Standards

Low finned cooler tubes are manufactured according to rigorous international standards to ensure performance consistency and material reliability across diverse operating environments.

International Standards Compliance

| Standard | Scope | Common Material Grades |

|---|---|---|

| ASTM B111 / ASME SB111 | Seamless copper and copper alloy heat exchanger tubes | C12000, C12200, C44300, C68700, C70600, C71500 |

| EN12451 / EN12449 | European standards for copper alloy heat exchanger tubes | Cu-DLP, Cu-DHP, CuZn28Sn1As, CuZn20Al2As, CuNi10Fe1Mn, CuNi30Mn1Fe |

| BS British Standard | British standards for heat exchanger tubes | CZ106, CZ111, CZ110, CN102, CN106 |

| JIS H3300 | Japanese standards for copper alloy tubes | C1201, C1220, C4430, C6870, C7060, C7150 |

Chemical Composition Analysis

The performance characteristics of low finned cooler tubes are directly influenced by their precise chemical composition, which is carefully controlled during manufacturing to ensure optimal thermal conductivity, corrosion resistance, and mechanical strength.

| Material Type | Chemical Composition | Key Properties |

|---|---|---|

| Copper (C12000/C12200) | Cu≥99.90 | Excellent thermal conductivity, good corrosion resistance |

| Copper-Zinc-Tin (Admiralty) | 70.0≤Cu≤73.0; 0.8≤Sn≤1.2; Zn Rem; 0.02≤As≤0.06 | Superior corrosion resistance in freshwater and marine environments |

| Aluminum Brass | 76.0≤Cu≤79.0; 1.8≤Al≤2.5; Zn Rem; 0.02≤As≤0.06 | Enhanced resistance to impingement attack and dezincification |

| Copper-Nickel Alloys | 9.0≤Ni≤33.0; 0.4≤Fe≤1.8; Cu Rem | Excellent marine corrosion resistance, biofouling resistance |

Dimensional Specifications

Low finned cooler tubes are available in precise dimensional ranges to accommodate various heat exchanger designs and performance requirements.

Standard Dimensions

Outside Diameter: 12mm - 30mm

End Wall Thickness: 1.2mm - 3.25mm

Fin Height: 0.90mm - 2.50mm

Wall Under Fin: 0.65mm - 2.82mm

Performance Considerations

The fin density typically ranges from 630 to 1575 fins per meter (16-40 fins per inch), creating an optimal balance between increased surface area and minimal flow resistance.

The finned section generally covers 80-90% of the tube length, with plain ends provided for proper seating in tube sheets.

Microscopic view of low finned cooler tube showing precise fin geometry and surface structure

Industrial Applications

Low finned cooler tubes serve critical functions across multiple industries where efficient heat transfer is essential for process optimization, energy efficiency, and equipment protection.

HVAC, refrigeration, and process heat exchangers benefit from compact designs with enhanced thermal performance.

Cooling process fluids, condensing vapors, and maintaining optimal temperatures in refining operations.

Critical components in condensers and heat exchange systems for steam condensation and gas cooling.

Temperature control in reactors, distillation columns, and various chemical manufacturing processes.

Pasteurization, sterilization, and cooling processes requiring hygienic heat transfer surfaces.

Efficient cooling of compressed air to improve system efficiency and prevent moisture issues.

Evaporators and condensers in commercial and industrial refrigeration applications.

Solar thermal systems and geothermal heat pumps for efficient renewable energy utilization.

Key Benefits and Advantages

Selection Considerations

When specifying low finned cooler tubes for a particular application, several critical factors must be considered to ensure optimal performance and longevity:

Operating Environment

The chemical composition of both the tube-side and shell-side fluids will determine the appropriate material selection. Corrosive environments may require copper-nickel alloys or specially treated surfaces, while clean applications may utilize standard copper or brass compositions.

Thermal Performance Requirements

The required heat transfer rate, temperature differentials, and flow rates will influence the optimal fin height, density, and tube diameter. Higher fin densities provide greater surface area but may increase pressure drop and fouling potential.

Mechanical Constraints

Operating pressures, vibration potential, and thermal expansion characteristics must be considered to ensure structural integrity throughout the equipments service life.

Maintenance Considerations

Applications with high fouling potential may benefit from lower fin heights and wider fin spacing to facilitate cleaning and reduce maintenance frequency.

low finned cooler tube Trends and Innovations

The development of low finned cooler tube technology continues to evolve, with recent advancements focusing on enhanced surface treatments, alternative materials including specialized alloys and composites, and precision manufacturing techniques that further optimize thermal performance while reducing material requirements. The integration of smart monitoring systems with low finned tube heat exchangers represents an emerging trend, enabling real-time performance optimization and predictive maintenance capabilities.