Lord Fin Tube-High Efficiency Pitted Tube

What is Pitted Tube?

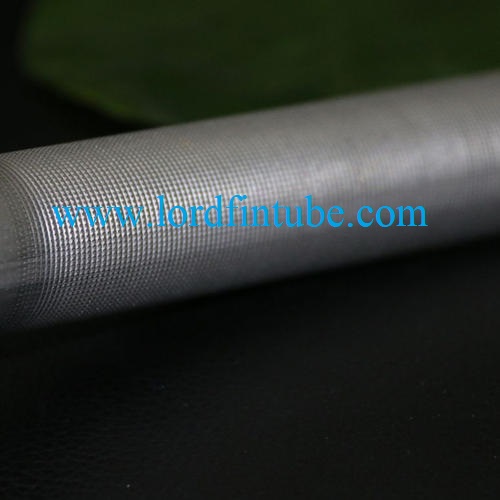

Pitted tubes, also known as enhanced surface tubes or grooved tubes, are specialized heat exchanger components featuring multiple sets of spiral grooves on the outer wall of the pipe body. These spiral grooves cover the entire external surface in a discontinuous pattern, typically arranged in two staggered groups. The unique configuration causes adjacent spiral grooves to extrude the enclosed outer wall sections into distinctive bulges, creating a textured surface that significantly enhances thermal performance.

The cross-section of the spiral grooves in pitted tubes typically forms an inverted triangle shape. This innovative design dramatically increases heat exchange efficiency, reduces the required amount of piping material, lowers production costs, and enables effective use in long-distance heat exchange applications where conventional tubes would be less efficient.

Key Performance Advantages

High efficiency pitted tubes represent a significant advancement over traditional smooth-surface heat exchange tubes. Through specialized surface enhancement techniques, these tubes achieve substantially improved overall heat transfer coefficients, typically ranging from 30% to 60% higher than equivalent smooth tubes under similar operating conditions.

Pitted Tubes Technical Specifications & Material Grades

Standard Specifications

Pitted Tubes Material Grade Comparison

| Material Grade | Composition | Corrosion Resistance | Temperature Range | Primary Applications |

|---|---|---|---|---|

| 304 Stainless Steel | 18% Cr, 8% Ni | Good | -200°C to 800°C | General purpose, food processing, mild chemical environments |

| 316 Stainless Steel | 16% Cr, 10% Ni, 2% Mo | Excellent | -200°C to 800°C | Marine environments, chemical processing, pharmaceutical |

| 2205 Duplex | 22% Cr, 5% Ni, 3% Mo, N | Outstanding | -50°C to 300°C | Offshore, oil & gas, high chloride environments |

| Inconel 600 | 76% Ni, 15% Cr, 8% Fe | Exceptional | -200°C to 1100°C | High temperature applications, nuclear, aerospace |

| Hastelloy C276 | 57% Ni, 16% Mo, 15% Cr | Superior | -200°C to 400°C | Severe corrosive environments, chemical reactors |

The selection of appropriate material grade depends on multiple factors including operating conditions, fluid composition, temperature extremes, pressure requirements, and specific corrosion concerns. Nickel alloys like Inconel and Hastelloy are typically reserved for the most demanding environments where exceptional corrosion resistance is paramount.

Pitted Tube Types & Configurations

Type 1: Outer Wall Pattern

Features spiral grooves exclusively on the external surface while maintaining a smooth inner wall. This configuration is ideal for applications where enhanced external heat transfer is the primary requirement while maintaining minimal pressure drop internally.

Applications: Shell and tube heat exchangers, condensers with external phase change

Type 2: Inner & Outer Wall Pattern

Incorporates enhanced surfaces on both internal and external walls, providing maximum heat transfer improvement. This design is suitable for applications requiring balanced heat transfer enhancement on both sides of the tube wall.

Applications: Double-pipe heat exchangers, high-performance cooling systems

Type 3: High Heat Transfer Variant

Combines specialized internal patterns with enhanced external surfaces, optimized for maximum thermal performance. These tubes often feature proprietary groove geometries that create optimal turbulence and surface area expansion.

Applications: Critical heat exchange processes, compact heat exchangers

Performance Comparison by Type

| Tube Type | External Heat Transfer Enhancement | Internal Heat Transfer Enhancement | Pressure Drop Increase | Recommended Flow Conditions |

|---|---|---|---|---|

| Type 1 (External Only) | 40-60% | 0-5% | 10-20% | External boiling/condensation |

| Type 2 (Double-Sided) | 40-60% | 30-50% | 30-60% | Single-phase both sides |

| Type 3 (High Performance) | 50-70% | 40-60% | 40-70% | High-performance applications |

| Standard Smooth Tube | Baseline | Baseline | Baseline | General purpose |

Pitted Tubes Manufacturing Process & Surface Enhancement

The manufacturing of pitted tubes involves sophisticated mechanical deformation processes that transform ordinary smooth-surface heat exchange tubes into high-performance thermal transfer components. The enhancement is achieved through precision extrusion and rolling operations that create specific patterns on the tube surfaces.

Enhancement Techniques

These physical modifications work synergistically to improve the overall heat transfer coefficient of the heat exchange tube. The combination of increased surface area and enhanced fluid dynamics results in significantly improved thermal performance compared to conventional smooth tubes.

Pitted Tubes Applications & Industry Usage

Pitted tubes find extensive application across multiple industries where efficient heat transfer is critical to process performance and energy efficiency.

Key Application Areas

Lithium Bromide Absorption Systems

Widely used in lithium bromide absorption chillers (non-electric air conditioning) where they significantly improve the efficiency of the absorption refrigeration cycle. The enhanced surfaces promote more effective heat and mass transfer in both the generator and absorber sections.

Evaporation Heat Exchange

Employed in various evaporation heat exchange applications including multi-effect evaporators, falling film evaporators, and other phase-change heat transfer systems. The surface enhancements promote nucleation sites for more efficient boiling.

Power Generation

Critical components in power plant heat exchangers, condensers, and feedwater heaters where they contribute to improved thermal efficiency and reduced equipment footprint.

Chemical Processing

Utilized in reactors, reboilers, and process heaters in chemical plants where corrosion-resistant materials combined with enhanced heat transfer provide operational advantages.

HVAC&R Systems

Applied in commercial and industrial heating, ventilation, air conditioning and refrigeration systems to improve energy efficiency and reduce system size.

Marine & Offshore

Specialized applications in shipboard systems and offshore platforms where space constraints and harsh environments demand compact, efficient, and durable heat exchange solutions.

Pitted Tubes Performance & Efficiency Data

Heat Transfer Enhancement Comparison

| Application Scenario | Smooth Tube Performance | Pitted Tube Performance | Improvement Percentage | Material Savings Potential |

|---|---|---|---|---|

| Water-to-Water Heat Exchange | Baseline | 40-50% higher | 40-50% | 25-35% |

| Refrigerant Evaporation | Baseline | 50-70% higher | 50-70% | 30-40% |

| Steam Condensation | Baseline | 45-60% higher | 45-60% | 25-35% |

| Oil Cooling | Baseline | 30-45% higher | 30-45% | 20-30% |

| High-Viscosity Fluids | Baseline | 35-55% higher | 35-55% | 20-35% |

Economic & Environmental Benefits

The implementation of pitted tubes in heat exchange systems typically delivers substantial economic and environmental advantages. Systems utilizing enhanced surface tubes can achieve the same thermal duty with 20-40% less heat transfer area, resulting in reduced material consumption, smaller equipment footprints, and lower initial capital investment. Additionally, the improved thermal efficiency translates to reduced energy consumption during operation, with typical energy savings ranging from 15-30% compared to systems using conventional smooth tubes.

Pitted Tubes

Pitted tubes represent a significant advancement in heat transfer technology, offering substantial improvements in thermal efficiency, material utilization, and overall system performance. The unique surface enhancement techniques employed in these tubes create turbulent flow conditions, increase effective surface area, and disrupt thermal boundary layers, resulting in heat transfer coefficients that are typically 30-70% higher than equivalent smooth tubes.

Available in various configurations including external-only, double-sided, and high-performance variants, pitted tubes can be tailored to specific application requirements across industries including HVAC&R, power generation, chemical processing, and absorption cooling systems. With material options ranging from standard stainless steels to specialized nickel alloys, these enhanced heat transfer components provide reliable performance even in demanding corrosive and high-temperature environments.

The selection of appropriate pitted tube type and material should be based on comprehensive analysis of operating conditions, fluid properties, thermal requirements, and economic considerations. When properly specified and applied, pitted tubes deliver significant value through reduced equipment size, lower energy consumption, and improved process efficiency.

For more detailed technical information about pitted tubes and other enhanced heat transfer surfaces, visit our comprehensive resource on pitted pipe technology and applications.