Lord Fin Tube-Titanium low finned tube

What is titanium low finned tube?

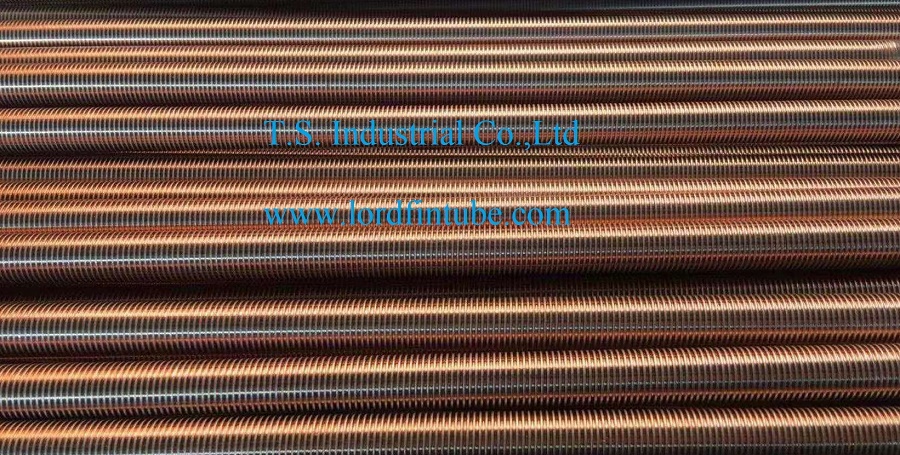

Titanium low finned tube is an extruded tubing made up of small low fins. The low fin tube is similar to the extruded "high fin" types, but it has the same diameter as the base tube. Low Fin Enhanced tubes are suitable for use in standard shell and tube baffles as well as tube sheets. The primary advantage of low fin tubes is that they provide surface enhancement and superior heat transfer over smooth tubing. Titanium low finned tube normally produced by standard ASTM B338 Gr.2.

Fin material is tightly wound around the outside of the tube during the manufacturing process to ensure metal-to-metal contact of the fins base with the tube.

Titanium low finned tube has the advantage of improving the thermal performance of a Heat Exchanger without changing the shell size, flow arrangement, or piping positioning. The external surface of the tube is increased by the direct extrusion of "low fins" from the material of the base tube.

Titanium low finned tube Advantage:

The external surface area of a titanium low finned tube is 2.5 to 3 times that of a bare tube.

This has numerous advantages for heat transfer equipment.

Capital cost savings for new equipment

Because of the increased heat exchange efficiency, less Fine-Fin tubing is required to achieve the same heat transfer as a bare tube.

Retrofitting costs for existing equipment are reduced.

Fine-Fin can improve the performance of an existing heat exchanger without having to build new shells, heads, nozzles, piping, and foundations.

Space, weight & structural savings

In offshore production or high elevation distillation columns, reduced plot space and weight can be extremely valuable. Fine-Fin technology reduces the size of large shell and tube heat exchangers.

Fine-Fin tubing is available in a wider range of alloys than traditional low-fin tubing, which is limited to soft metals. This opens up a whole new world of possibilities for enhanced tubing in corrosive service. The greater the cost savings of Fine-Fin, the more expensive the tube material.

Lower maintenance and life cycle costs

With Fine-Fin, proper material selection can eliminate costly downtime and maintenance. For example, coastal refineries that use once-through seawater cooling systems can benefit from Titanium Fine-Fin tubing instead of traditional copper nickel tubing. Titanium Fine-Fin is highly resistant to corrosion and erosion caused by seawater.

Titanium low finned tube application:

Integral low fin tubes are commonly used in chemical processes. Particularly useful between air or other gases on the fin side and a fluid on the tube side.

When Should You Consider an Integral Low Fin Tube?

Shell side heat transfer is in charge.

Expensive building materials are required.

Decoupling an existing exchanger.

Upgrade or retrofit with new tube material.

Meeting a strict space or weight limit.