Tubesheet application

Tubesheet application

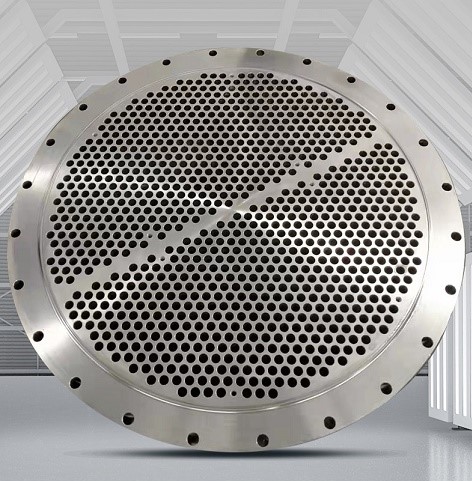

A tube sheet is a component that is used in shell-and-tube heat exchangers and other types of pressure vessels. It provides a support structure for the tubes, as well as a sealing surface for the tube ends. The tube sheet is typically a thick, circular plate with holes drilled into it for the tubes to pass through.

In an application, the tube sheet is used to keep the tubes in place and to provide a surface for sealing them to prevent leakage. It is also used to distribute the fluid being heated or cooled across the tubes, ensuring that the heat transfer process is efficient. Tube sheets are commonly used in industries such as chemical processing, power generation, and oil and gas refining.

The selection of the appropriate material for the tube sheet is critical, as it must be able to withstand high temperatures, pressures, and corrosive substances. Common materials used for tube sheets include stainless steel, carbon steel, and various alloys. Additionally, the design of the tube sheet and the arrangement of the tubes must be carefully considered to ensure optimal heat transfer and efficiency.

some more details on tube sheet applications:

1. Tube sheets are used in various types of heat exchangers, including shell-and-tube, double-pipe, and plate heat exchangers. In each of these applications, the tube sheet plays a critical role in ensuring efficient heat transfer.

2. In shell-and-tube heat exchangers, the tube sheet is typically located at both ends of the shell, and it is the point at which the tubes are attached. The tubes are often expanded into the holes drilled in the tube sheet to create a strong and reliable seal.

3. Tube sheets can also be used in other types of pressure vessels, such as distillation columns, condensers, and boilers. In these applications, the tube sheet is used to provide support for the tubes and to prevent them from moving under pressure.

4. The thickness of the tube sheet depends on various factors, such as the diameter and number of tubes, the design pressure, and the material properties. The thickness is typically determined by using industry standards and calculations to ensure that the tube sheet can withstand the pressure and stress it will be subjected to during operation.

5. Tube sheets can be manufactured using various methods, including forging, casting, and machining. The method used depends on factors such as the material, the size and shape of the tube sheet, and the desired finish.

6. Tube sheets are an important component in many industrial applications, and their proper design and selection can significantly impact the performance and efficiency of the equipment. It is important to consult with an experienced engineer or supplier to ensure that the tube sheet is properly designed and fabricated for the intended application.