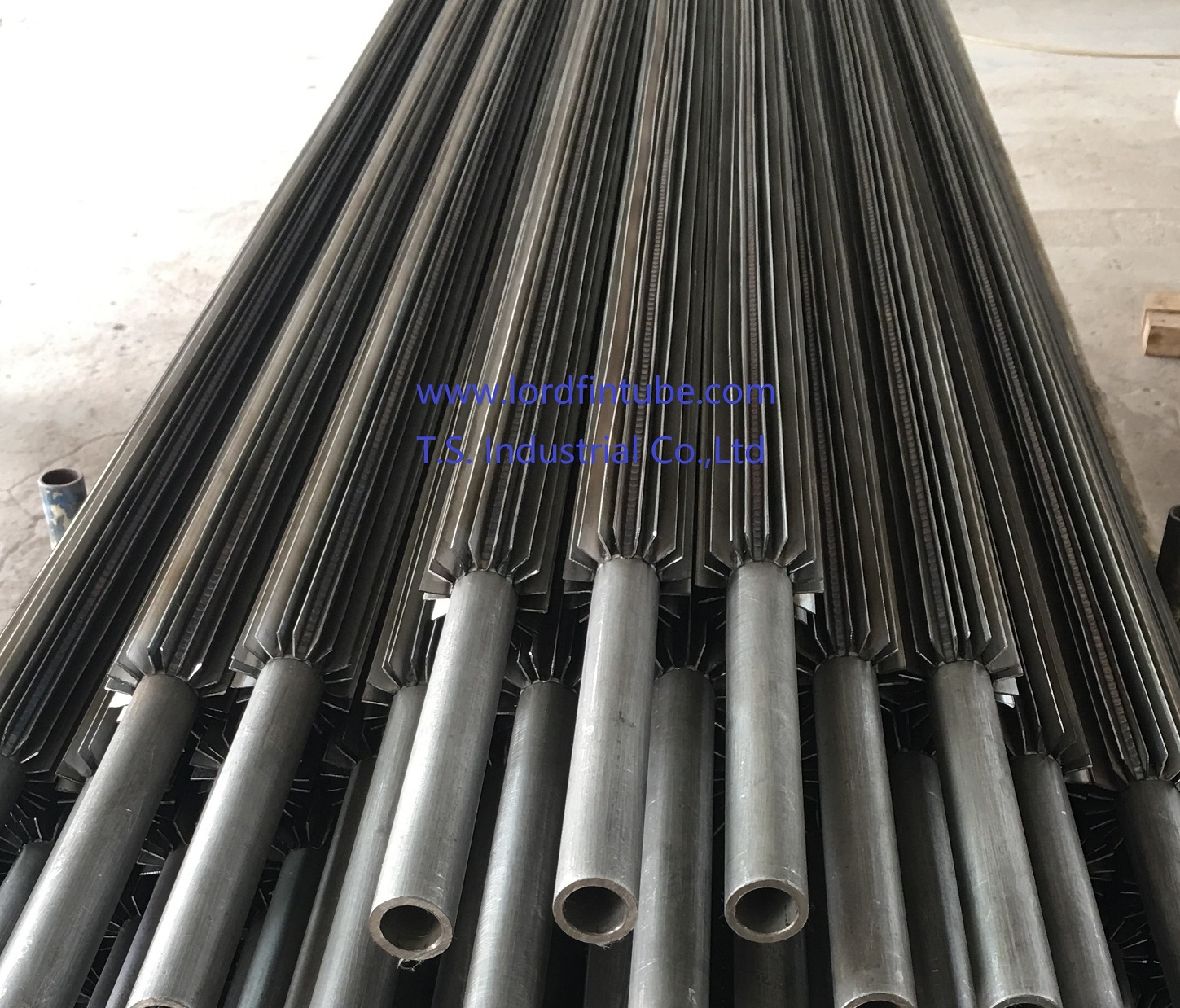

Longitudinally welded fin heat exchange tube

What Are Longitudinal Welded Fin Heat Exchange Tubes?

Longitudinal welded fin heat exchange tubes are critical components in thermal management systems, specifically engineered with fins extending parallel to the tube axis. This configuration maximizes the heat transfer surface area while maintaining efficient fluid flow characteristics.Longitudinally welded fin heat exchange tubes represent an advanced engineering solution for enhancing heat transfer efficiency in various industrial applications. These specialized components feature fins that extend parallel to the tube axis, significantly increasing the heat transfer surface area while maintaining optimal fluid dynamics.

Unlike conventional heat exchange tubes, longitudinally finned tubes offer superior performance in applications requiring:

Longitudinally Fin Tube Manufacturing Process and Technical Innovation

Background and Evolution

Traditional heat exchange solutions including L-shaped finned tubes, spiral finned tubes, and H-shaped finned tubes present significant limitations in high-performance applications. These conventional designs often suffer from excessive flow resistance, reduced heat transfer coefficients, and higher operational costs.

Performance Data: Longitudinal fin tubes demonstrate up to 40% higher heat transfer efficiency compared to traditional spiral fin designs while reducing pressure drop by approximately 25-30% in gas-to-liquid applications.

Advanced Manufacturing Technique

The longitudinally welded fin heat exchange tube employs precision laser welding technology to attach V-shaped longitudinal fins to the core tube. This advanced manufacturing process ensures:

Longitudinally Fin Tube Technical Specifications and Material

| Parameter | Carbon Steel | Stainless Steel | Titanium Alloy |

|---|---|---|---|

| Max Operating Temperature | 450°C | 800°C | 600°C |

| Pressure Rating | Up to 300 bar | Up to 250 bar | Up to 200 bar |

| Thermal Conductivity | 45-65 W/mK | 15-25 W/mK | 15-21 W/mK |

| Corrosion Resistance | Moderate (with coating) | High | Exceptional |

| Typical Applications | Power plants, boilers | Chemical processing, food industry | Marine, aerospace, chemical |

Performance Comparison: Longitudinal vs. Traditional Fin Tubes

| Feature | Longitudinal Fin Tube | Spiral Fin Tube | L-Foot Fin Tube |

|---|---|---|---|

| Heat Transfer Efficiency | High (30-40% improvement) | Medium | Medium-Low |

| Pressure Drop | Low | Medium-High | Medium |

| Fouling Resistance | Excellent | Poor | Fair |

| Manufacturing Complexity | High (precision welding) | Medium | Low |

| Maintenance Requirements | Low | High | Medium |

| Space Efficiency | Excellent | Good | Fair |

Longitudinally Fin Tube Industrial Applications

Power Generation

Used in economizers, air preheaters, and heat recovery systems in thermal power plants for improved energy efficiency.

Chemical Processing

Ideal for reactors, distillation columns, and heat exchangers handling corrosive media at elevated temperatures.

HVAC & Refrigeration

Employed in large-scale industrial chillers, condensers, and heat pumps for superior thermal performance.

Oil & Gas

Critical components in heaters, coolers, and process heat exchangers in refineries and petrochemical plants.

Longitudinally Fin Tube Engineering Advantages

Thermal Performance

The rectangular cross-sectional profile of longitudinally finned tubes creates an optimal balance between heat transfer surface area and fluid dynamics. This configuration allows for:

Structural Integrity

Laser welding creates a metallurgical bond between fins and the core tube, resulting in:

Longitudinally Fin Tube Design Considerations

When implementing longitudinally welded fin tubes, engineers must consider several critical factors:

Longitudinally Fin Tube

Longitudinally welded fin heat exchange tubes represent a significant advancement in thermal engineering, offering superior performance characteristics compared to traditional finned tube designs. Through precision laser welding and optimized geometric configuration, these components deliver enhanced heat transfer efficiency, reduced pressure drop, and exceptional durability in demanding industrial applications.

With material options including carbon steel, stainless steel, and titanium alloys, longitudinally finned tubes can be tailored to specific operational requirements across power generation, chemical processing, HVAC, and oil & gas industries. The elimination of tube plates in bundle configurations further enhances space utilization while simplifying maintenance procedures.