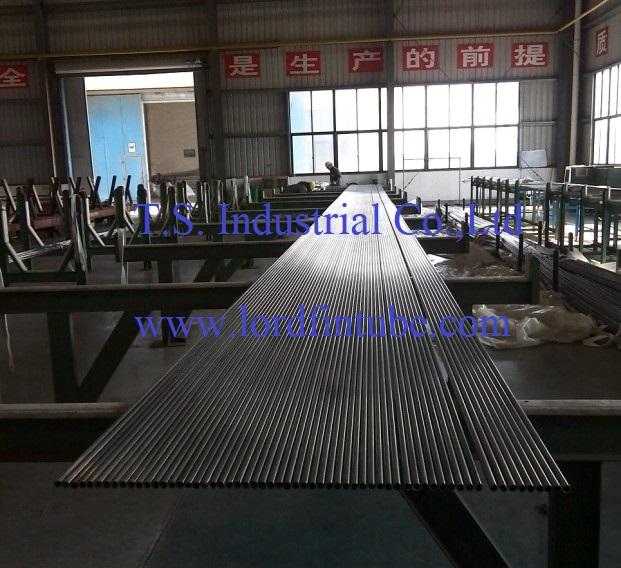

Lord Fin Tube-Ultra-long stainless steel tube

Ultra-Long Stainless Steel Tubes

Discover how ultra-long stainless steel tubes are transforming industries with their exceptional durability, corrosion resistance, and seamless performance in demanding environments.

Ultra-Long Stainless Steel Tubes

Ultra-long stainless steel tubes represent a specialized category of tubular products characterized by their exceptional length, typically exceeding standard industry measurements. While theres no universally defined threshold, these tubes generally measure several meters to tens of meters in length, with some specialized applications requiring tubes exceeding 20 meters.

Characteristics

These tubes maintain dimensional stability and material integrity across their entire length, featuring precise wall thickness consistency, superior surface finish, and excellent mechanical properties that remain uniform regardless of length.

Manufacturing Excellence

The production of ultra-long stainless steel tubes involves advanced manufacturing techniques including continuous welding processes, specialized heat treatment, and precision cold drawing. Modern manufacturers employ sophisticated quality control systems with automated ultrasonic testing and eddy current inspection to ensure flawless performance across extended lengths.

Industrial Applications of Ultra-Long Stainless Steel Tubes

Oil & Gas Industry

Ultra-long tubes serve as critical components in offshore drilling platforms, subsea pipelines, and deep-water exploration systems. Their extended length reduces connection points, minimizing potential leak paths and installation time in challenging marine environments.

Petrochemical Processing

In refinery applications, these tubes enable the construction of longer heat exchanger bundles and reactor coils, improving thermal efficiency and reducing maintenance downtime in corrosive chemical processing environments.

Power Generation

Ultra-long stainless steel tubes are essential in power plant boiler systems, condenser units, and heat recovery steam generators, where extended single-length tubes enhance thermal transfer efficiency and reduce system complexity.

Infrastructure Development

Modern architectural projects utilize these tubes for structural supports in bridges, tunnels, and high-rise buildings, where their length provides superior load distribution and reduces construction joints.

Technical Specifications and Material Properties

| Property | Standard Grades | Premium Grades | Applications |

|---|---|---|---|

| Maximum Length | Up to 12 meters | 12-25+ meters | Varies by application requirements |

| Common Alloys | 304, 304L, 316, 316L | 321, 347, 904L, Duplex | Selected based on corrosion resistance needs |

| Temperature Range | -200°C to 400°C | -270°C to 800°C | High-temperature applications |

| Pressure Rating | Standard pressure | High-pressure capable | Critical for safety systems |

Advantages of Ultra-Long Stainless Steel Tubes

Enhanced Performance

The reduced number of joints in ultra-long tube installations significantly decreases potential failure points, enhancing system reliability and reducing maintenance requirements. This is particularly crucial in applications where accessibility is limited or repair costs are substantial.

Cost Efficiency

While initial material costs may be higher, the total installed cost often proves more economical due to reduced welding requirements, fewer fittings, and decreased installation time. Lifecycle cost analysis typically shows significant savings over conventional tube systems.

Improved Flow Characteristics

Continuous ultra-long tubes provide smoother internal surfaces with minimal disruptions, resulting in improved fluid dynamics, reduced pressure drops, and enhanced system efficiency in both liquid and gas transportation applications.

Installation and Handling Considerations

Specialized equipment and techniques are required for the proper handling and installation of ultra-long stainless steel tubes. Transportation logistics must account for the exceptional length, while installation crews require specific training to prevent deformation or damage during placement.

Best Practices

Proper support spacing, controlled bending radii, and specialized joining techniques are essential for maintaining tube integrity. Professional engineering consultation is recommended for all ultra-long tube applications to ensure optimal performance and safety.