ASTM A498 Heat-Exchanger Integral Finned Tubes

ASTM A498/A498M-2014 establishes the specifications for Seamless and Welded Carbon Steel Heat-Exchanger Tubes with Integral Fins, ensuring high-quality performance in heat exchange applications.

4. Material and Manufacture of ASTM A498 Heat-Exchanger Integral Finned Tubes

4.1 The production of finned tubes necessitates the utilization of plain tubes meeting the rigorous standards outlined in Specifications A179/A179M, A214/A214M, or A334/A334M. These specifications guarantee the requisite quality and durability of the base material for the finned tubes.

4.2 It is noteworthy that any mandatory tests mandated in the specifications for plain tubes, which are conducted on unfinned tube lengths as per ASTM A498, are exempt from repetition on the plain tube. This exemption streamlines the manufacturing process while ensuring consistent quality.

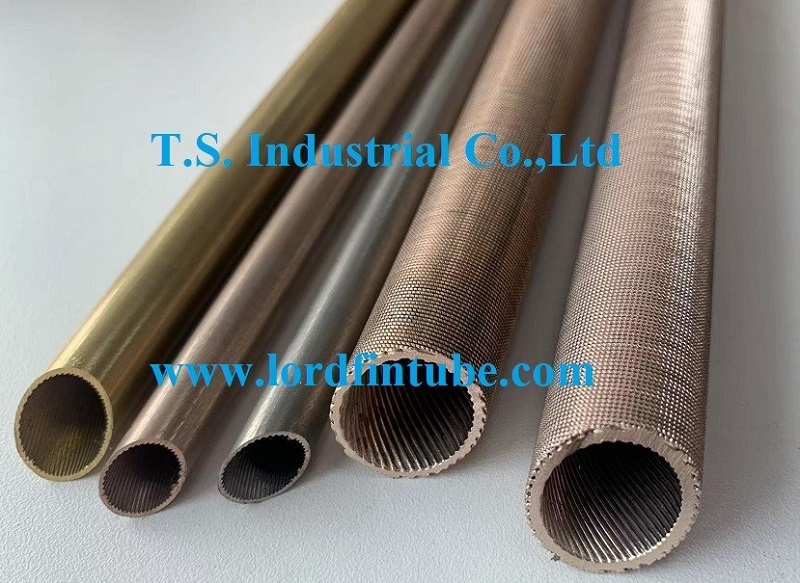

4.3 The formation of fins involves the cold shaping of prime-surface steel tubes. This process demands uniformity in both the fin and tube materials to meet the stringent requirements of the specification. Homogeneity is vital for achieving the desired structural integrity and performance of the finned tubes.

4.4 While finned tubes are typically supplied with unfinned ends, the specification allows for the provision of finned ends upon specific request. This flexibility accommodates diverse application needs and installation requirements.

5. Heat Treatment of ASTM A498 Heat-Exchanger Integral Finned Tubes

5.1 Following the finning process, tubes are delivered in either the annealed or as-fabricated condition, as specified by the purchaser. The choice between these conditions depends on factors such as the intended application and the desired mechanical properties of the tubes.

5.2 The annealed condition entails subjecting both the finned and unfinned portions of the tube to the appropriate heat-treatment regimen prescribed by the governing ASTM specification for the steel tube analysis involved. This treatment optimizes the material properties for enhanced performance and longevity.

5.3 Conversely, the as-fabricated condition refers to the state wherein the finned portions of the tube retain the characteristics attained during the finning operation, such as the as-finned or cold-worked state. Meanwhile, the unfinned or plain tube sections of the finned tube are in the as-fabricated condition, suitable for subsequent rolling-in operations. This condition ensures that the tubes are ready for further processing or installation as per the requirements of the application.

6. Chemical Composition of ASTM A498 Heat-Exchanger Integral Finned Tubes

6.1 The chemical composition of the steel used in manufacturing the finned tubes must conform to the stringent requirements specified in the governing plain-tube specification. Adherence to these requirements ensures the desired material properties and performance characteristics essential for heat-exchanger applications.

7. Tensile Requirements of ASTM A498 Heat-Exchanger Integral Finned Tubes

7.1 Prior to the finning operation, or in the case of unfinned portions of the finned tube, compliance with the prescribed tensile properties outlined in the governing plain-tube specification is mandatory. This requirement ensures that the tubes possess the necessary mechanical strength and resilience to withstand the rigors of operation and environmental factors encountered in heat-exchanger applications.