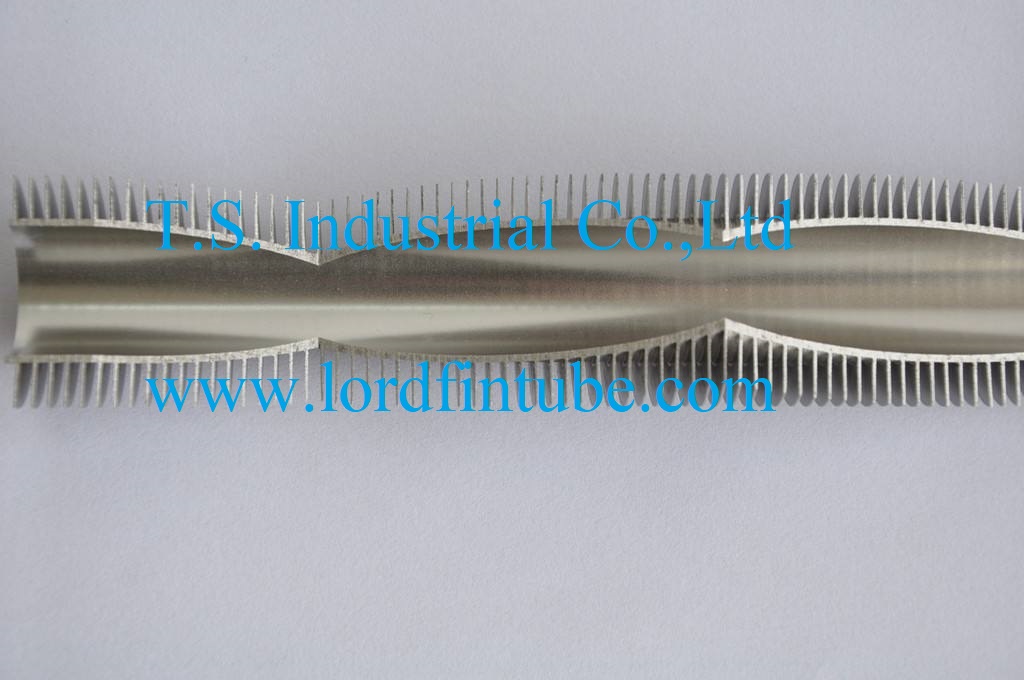

Laser welding spiral finned tube

2021-05-12Leave a message

The welding equipment of laser welding spiral finned tube is composed of a high-power automatic laser welding machine, full-automatic numerical control fixture, automatic feeder and other auxiliary equipment.

The five characteristics of spiral finned tube laser welding:

1: the thickness of base tube can be 0.8-1.5 mm, the thickness of fin can be 0.3-1 mm, which greatly saves the material cost compared with other processes. 2: High penetration rate can prevent gap corrosion, prolong service life and reduce heat transfer resistance. 3: Breaking through the limitation of materials, different materials can be used for processing. 4: Easy to secondary processing, can be directly coil and elbow. 5: The welding heat affected zone is small and the metallographic change is small, which makes it possible to process the small diameter finned tube.

The quality control of laser welded spiral finned tube is as follows

The quality control of laser welded spiral finned tube is as follows1. CCD monitoring system is used in the production process to monitor the whole welding area. 2. First article approval, use metallographic analysis system to get welding status, and ensure product quality before continuous production. 3. Select high quality and high specification materials and start from the source to ensure the quality of products. 4: Breaking through the limitation of materials, different materials can be used for processing. 5: Easy to secondary processing, can be directly coil and elbow. 6: The welding heat affected zone is small and the metallographic change is small, which makes it possible to process the small diameter finned tube. 7: The thickness of base tube and fin can be 0.8-1.5 mm and 0.3-1 mm respectively, which greatly saves the material cost compared with other processes.

The heat exchanger is the key equipment of the thermal system.

The tube fin heat exchanger is a kind of heat exchanger structure with high technology and complex production process. The cross flow heat transfer between the cold and hot fluid, the refrigerant in the tube, and the air outside the tube. The phase change heat transfer is the main body in the tube, the tube is usually multi tube, and the fin is divided into single, double or multi row structure. This kind of heat exchanger is widely used in petrochemical, aviation, vehicle, power machinery, air separation, cryogenic, atomic energy, aerospace and other industrial fields. For example, superheater, economizer, air preheater, condenser, deaerator, feed water heater, cooling tower, etc; Hot blast stove, air or gas preheater, waste heat boiler in metal smelting system, etc; Evaporator, condenser and regenerator in refrigeration and cryogenic system; Heating and cooling equipment widely used in petrochemical industry, sugar evaporator and pulp evaporator in sugar industry and paper industry are a large number of examples of heat exchanger application.