Knowledge about tube sheet drilling

Tube Sheet Drilling: Technology and Industrial Applications

Precision drilling solutions for heat exchangers, boilers, and industrial equipment

Introduction to Tube Sheet Drilling

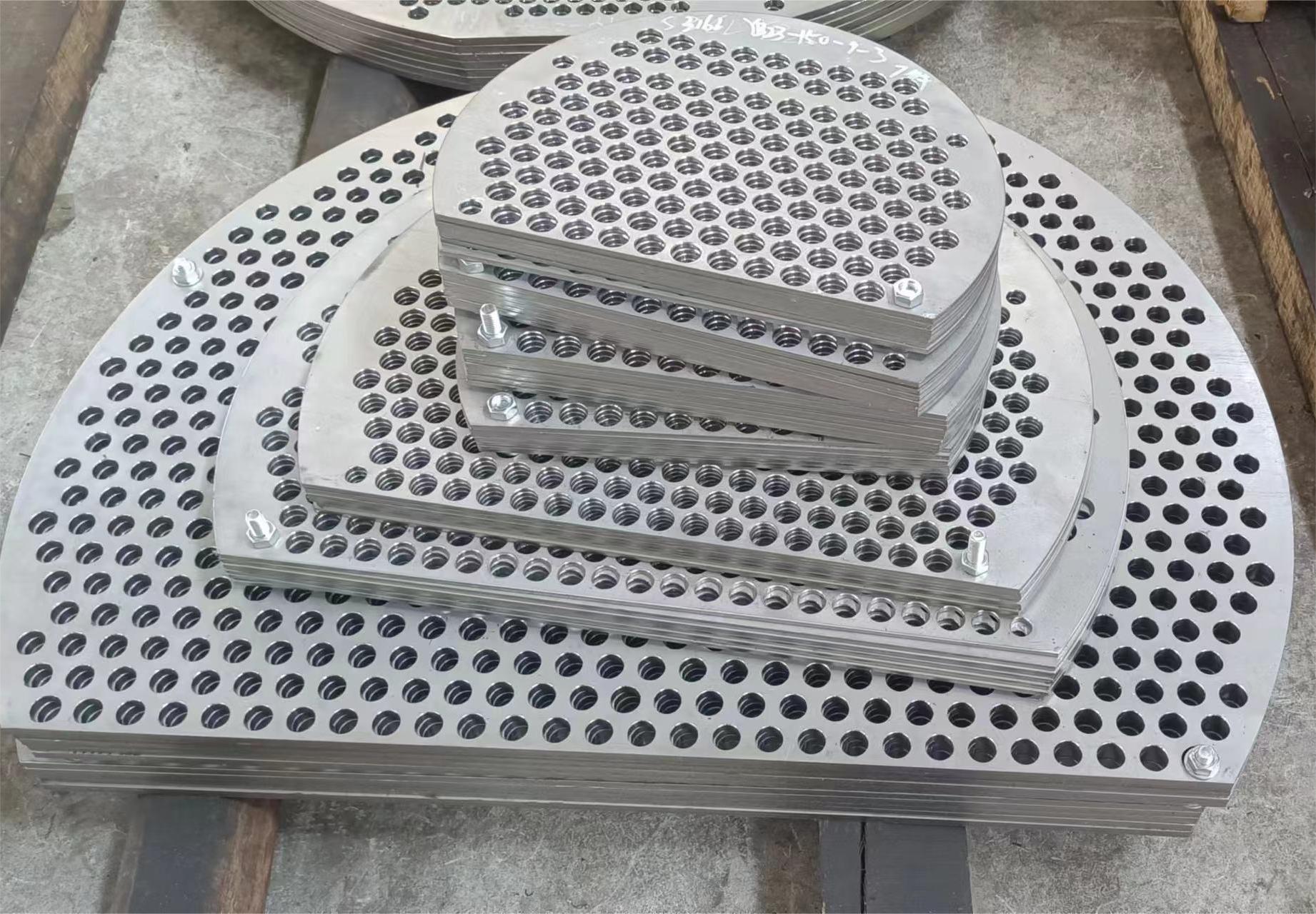

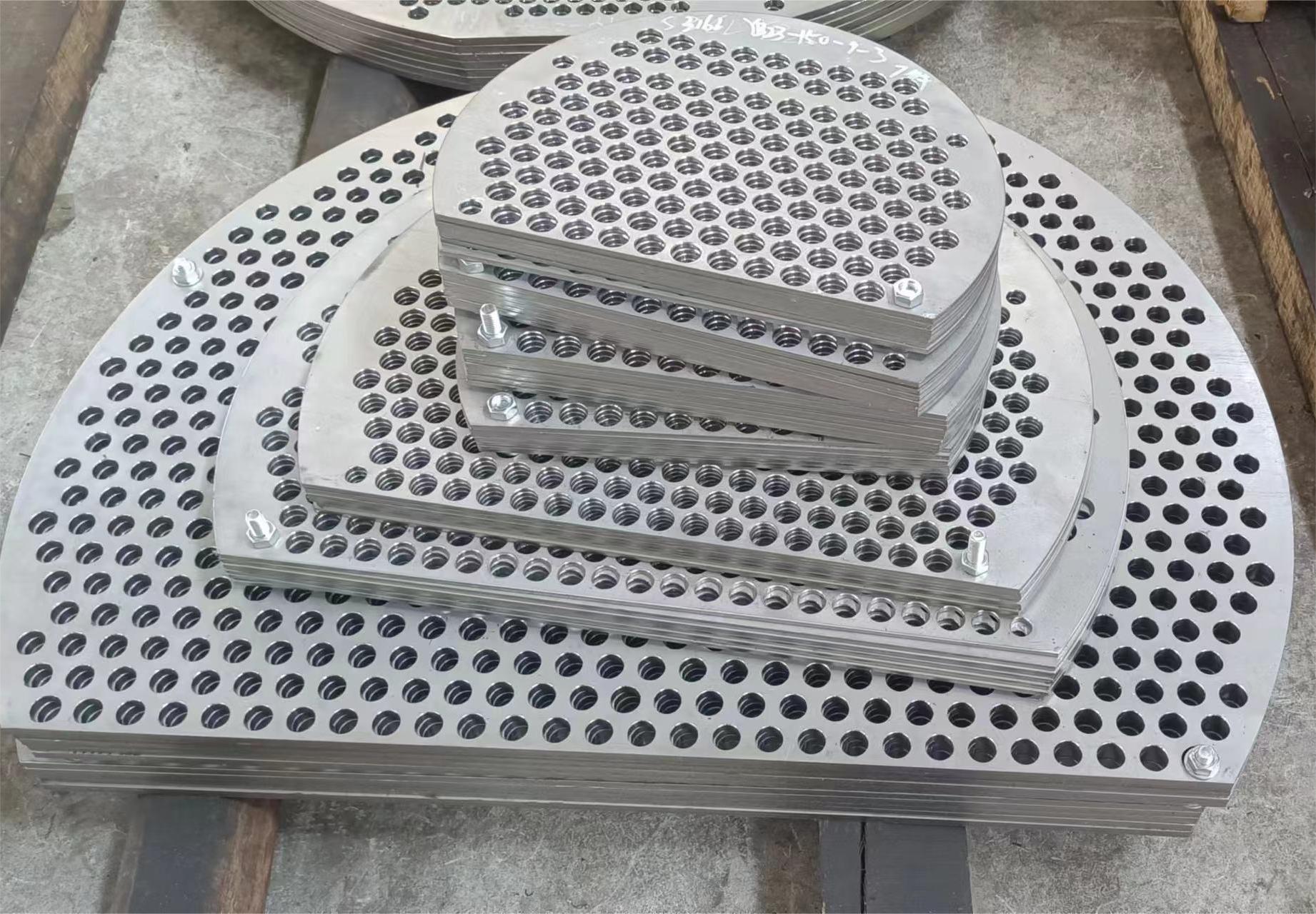

Tube sheet drilling is a critical precision machining process in industrial manufacturing, primarily used in the production of heat exchangers, boilers, steam turbines, and other thermal equipment. As the core component for supporting and fixing metal tubes, tube sheets require accurate processing of hundreds or even thousands of holes on thick steel plates. The precision requirements include exact hole dimensions, precise positioning, perfect verticality, and specific surface roughness specifications.

This process is particularly challenging when working with large diameter, high thickness, and high-strength metal materials. With increasing demand for large tube sheets in nuclear power, seawater desalination, power plants, and other advanced industries, tube sheet drilling services have evolved into an essential high value-added in the industrial supply chain.

Tube Sheet Drilling Technology

1. Drilling Methods

Traditional Mechanical Drilling

Equipment: Radial drilling machines, vertical drilling machines

Features: Suitable for small batch production, offers operational flexibility, but accuracy and efficiency depend heavily on operator skill and experience.

Process Steps: Marking and positioning → Center hole pre-drilling → Stage drilling (such as step drilling) → Reaming for finish.

CNC Drilling

Equipment: CNC drilling machines, machining centers

Features: High automation level, ideal for mass production, achieves hole position accuracy up to ±0.05mm, supports complex hole types (including angled holes and threaded holes).

Advantages: Automated drilling path generation through programming minimizes human error, supports multi-axis linkage for complex operations.

Laser Drilling

Equipment: High-power laser cutting machines

Features: Suitable for thin plates or special materials (titanium alloys, composites), eliminates tool wear, but involves higher equipment costs.

Water Jet Drilling

Equipment: High-pressure water jet cutting machines

Features: No heat-affected zone, ideal for heat-sensitive materials, though with slightly lower aperture accuracy compared to other methods.

2. Drilling Tools

Drill Bit Types

- Twist drills: General-purpose drills suitable for carbon steel, stainless steel, etc. Available in high-speed steel (HSS) or carbide materials (tungsten steel).

- Deep hole drills: Specialized for deep hole processing with aspect ratios > 10:1, feature internal cooling structures to address chip evacuation challenges.

- Step drills: Create multiple diameter holes in a single operation, significantly reducing tool change time.

- Reamers: Used for precision finishing to improve hole wall surface quality (achieving Ra ≤ 1.6μm).

- Chamfering tools: Remove burrs from hole openings and create guide bevels.

Auxiliary Tools

- Fixtures: Hydraulic or mechanical clamping systems to secure tube sheets firmly, preventing vibration-induced deviations.

- Cooling systems: Deliver cutting fluid (emulsion, oil-based coolant) through internal or external cooling to reduce temperature and provide lubrication.

- Guide sleeves: Ensure drill bit verticality and minimize runout errors.

Detection and Measurement Tools

- Measuring instruments: Digital calipers, height gauges, plug gauges (for hole diameter verification), coordinate measuring machines (CMM).

- Centering tools: Edge finders, laser centering instruments (specifically for CNC equipment).

Industry Applications of Tube Sheet Drilling

Energy and Power Generation

Nuclear power plant steam generators: Tube sheets must withstand extreme temperatures and pressures. Laser-mechanical composite processing ensures aperture consistency and reduces residual stress.

Offshore wind power heat exchangers: 316L stainless steel tube sheets require corrosion resistance for seawater applications, often needing electrolytic polishing after drilling operations.

Chemical and Petrochemical

Hydrogenation reactors: Duplex steel tube sheets require post-drilling penetrant testing (PT) and ultrasonic testing (UT) to ensure absence of crack defects and maintain structural integrity.

Heat exchangers for refineries: High-pressure applications demand precise tube sheet drilling with strict tolerance controls.

Emerging Technology Fields

Hydrogen energy storage and transportation equipment: Composite tube sheet drilling requires specialized techniques to avoid delamination. Ultrasonic vibration-assisted processing reduces cutting forces and improves results.

Solar thermal systems: Growing applications in concentrated solar power plants require precision-drilled tube sheets for efficient heat transfer.

Application Fields and Market Demand

Core Application Scenarios

- Energy industry: Nuclear power, thermal power, and petrochemical equipment have substantial tube sheet requirements, especially for high-temperature and high-pressure resistant alloy materials.

- Environmental protection: Seawater desalination equipment tube sheets require exceptional corrosion resistance, with increasing emphasis on environmental aspects of drilling processes (reducing waste emissions, improving sustainability).

- High-end manufacturing: Aerospace and precision instrument sectors show growing demand for micro-hole and special-shaped hole processing, driving adoption of laser and EDM (electrical discharge machining) technologies.

Market Driving Factors

- Infrastructure development: Global urbanization accelerates demand for heat exchangers and pressure vessels in water conservancy, transportation, and construction sectors.

- Policy support: Initiatives like Chinas "14th Five-Year Plan" emphasize high-end equipment manufacturing and green industry development, promoting drilling technology upgrades and environmental equipment investment.

- Energy transition: Shift toward renewable energy systems creates new applications for precision tube sheets in geothermal, biomass, and energy storage systems.

Tube sheet drilling

Tube sheet drilling represents a sophisticated manufacturing process that continues to evolve with advancing technologies. As industrial equipment demands greater efficiency, higher pressure tolerance, and enhanced corrosion resistance, precision drilling techniques must correspondingly advance. The future of tube sheet drilling will likely see increased automation, more sophisticated CNC systems, and growing adoption of hybrid processing methods that combine multiple technologies for optimal results across different materials and applications.