Products Description

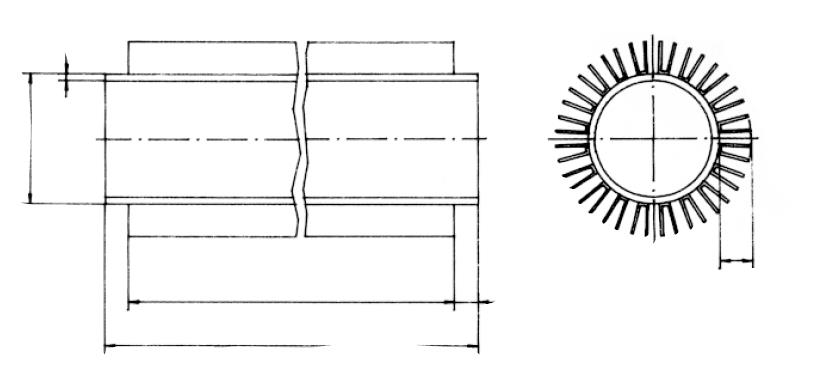

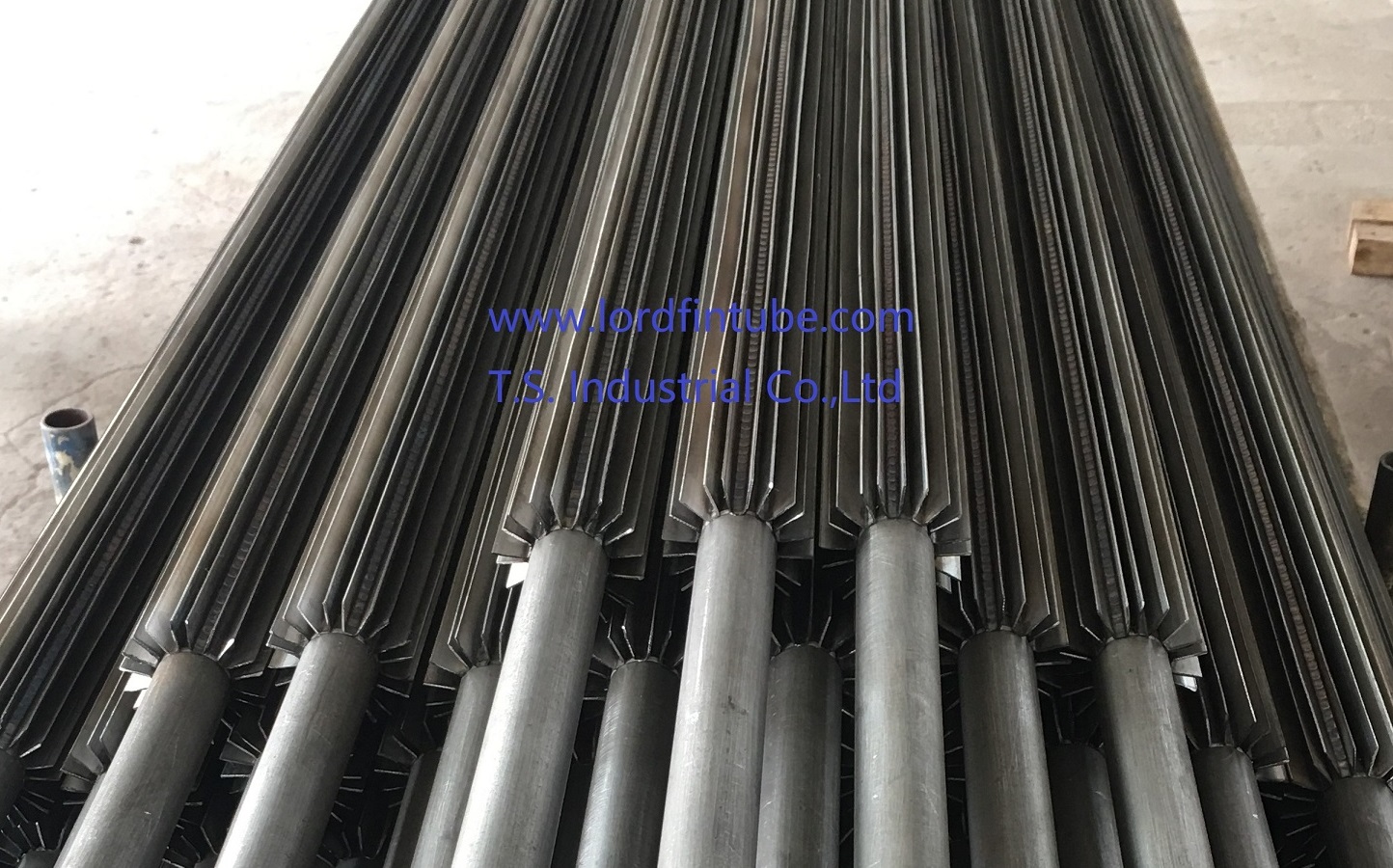

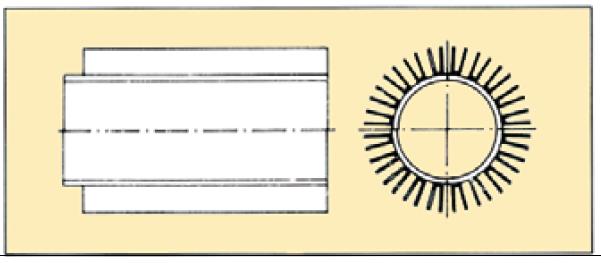

LFW Type Fin Tube| Longitudinal Finned Tube

I/L or U fins welded longitudinally onto the base tube. Also U-Bend execution possible

LFW Type Fin Tube Materials:

LFW Type Fin Tube Materials:

Carbon Steels, Alloy Steels, Stainless Steel, Nickel Alloys, and others

LFW Type Fin Tube Fields of application:

Chemical-, Petrochemical-, Oil-, Power Industry,Heat-Exchangers,Fired Heaters,Gas Coolers and Heaters,Tank Heaters

LFW Type Fin Tube Manufacturing process:

The longitudinal I/L or U fins are welded onto the base tubes by resistance welding or welding with filler metal. U-Bend tubes with LFW, Fins also possible.

LFW Type Fin Tube Advantages

LFW Type Fin Tube increase of heat transfer rates for viscous liquids. Perforated fin type used whenever drainage of liquid from fin channels become a problem. Widely used in horizontal heat-exchangers.

LFW Type Finned Tube Heat Exchanger:

1. Design: The LFW type finned tube heat exchanger typically consists of a set of tubes with external fins. These fins are attached to the outer surface of the tubes, increasing their surface area. The design of the fins can vary, but they are usually spiral or helical in shape.

2. Applications: LFW finned tube heat exchangers are used in a wide range of industries, including HVAC (Heating, Ventilation, and Air Conditioning), power generation, chemical processing, and more. They are particularly suitable for applications where there is a need to transfer heat between two fluids, such as air and a liquid or two different liquids.

3. Efficiency: The fins on the tubes serve to enhance heat transfer by increasing the surface area available for heat exchange. This design allows for more efficient cooling or heating of the fluids passing through the tubes.

4. Materials: The tubes and fins are typically made of materials that are compatible with the specific fluids and temperatures involved in the heat exchange process. Common materials include stainless steel, aluminum, and copper.

5. Maintenance: Regular maintenance is important to ensure the continued efficiency of LFW finned tube heat exchangers. This may involve cleaning the fins and tubes to prevent fouling or corrosion.

6. Cost Considerations: The cost of LFW type finned tube heat exchangers can vary depending on factors such as size, materials, and design specifications. They are often chosen when their efficiency and heat transfer characteristics are critical to the application.

7. Customization: LFW finned tube heat exchangers can be customized to meet specific requirements. Engineers and manufacturers can select the appropriate tube size, fin design, and materials to optimize performance for a particular application.

8. Fluid Compatibility: Its essential to ensure that the materials used in the heat exchanger are compatible with the fluids being processed. This helps prevent corrosion and ensures the longevity of the equipment.

In order to forward you a promt offer we would be pleased to receive you detailed enquiry containing:

• Base tube material and quantity

• Base tube size

• Fin material

• Fin type

• Fin diameter or height

• Fin thickness

• Fins per inch, meter or fin pitch

• Lenght of plain, unfinned ends

(nessesary to roll or weld the tubes into tubeplate or assembly)