A Guide to Helical Thermal Oil Coil

Helical Thermal Oil Coils

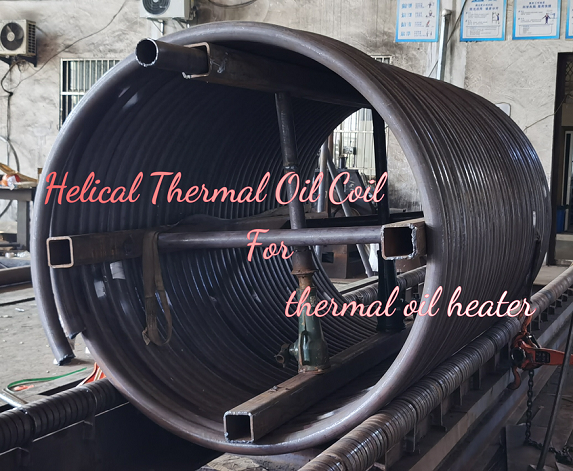

Helical thermal oil coils are essential components in thermal oil heating systems, offering exceptional efficiency in heat transfer applications across various industries. This comprehensive guide explores the design, functionality, manufacturing process, and applications of helical thermal oil coils to help engineers and industry professionals understand their critical role in industrial heating systems.

What is a Helical Thermal Oil Coil?

A helical thermal oil coil is a specialized heat exchange element used in thermal oil heating systems. It serves as the primary pressure-bearing component within these systems, responsible for transferring thermal energy from combustion sources to heat transfer oil in a closed-loop configuration.

Unlike conventional straight-tube heat exchangers, helical coils feature a spiral design that maximizes surface area for enhanced heat transfer efficiency. This innovative configuration creates turbulent flow within the thermal oil, significantly improving heat transmission rates compared to linear pipe arrangements.

Helical Thermal Oil Coil - Advanced Heat Transfer Component

These coils are typically fabricated from high-grade seamless steel pipes, with material selection based on operational temperature requirements and the specific characteristics of the thermal oil medium. Common materials include carbon steel for standard applications and stainless steel for corrosive environments or higher temperature operations.

Working Principle of Helical Thermal Oil Coils

The operational principle of helical thermal oil coils revolves around efficient heat transfer in a closed-loop system:

- Heat Absorption: The outer surface of the coil absorbs thermal energy generated by fuel combustion (gas, oil, biomass, or electric elements)

- Heat Transfer: This thermal energy is conducted through the pipe wall to the thermal oil circulating inside the coil

- Fluid Circulation: A high-temperature circulating pump maintains continuous flow of thermal oil through the coil system

- Heat Distribution: The heated thermal oil transfers its energy to process equipment through secondary heat exchangers

- Return Cycle: After heat transfer, the cooled thermal oil returns to the coil for reheating, completing the closed-loop cycle

The helical design induces secondary flow patterns (Dean vortices) that significantly enhance heat transfer coefficients by 20-40% compared to straight tubes, while simultaneously reducing fouling tendencies.

Design Structure and Configuration

Helical thermal oil coils feature sophisticated engineering designs optimized for maximum thermal efficiency and structural integrity:

Inner Coil Design

Located closest to the heat source, inner coils typically feature tighter spiral patterns to maximize heat absorption from high-temperature combustion gases.

Outer Coil Configuration

Positioned further from the heat source, outer coils often have larger diameters and are designed to capture residual heat, improving overall system efficiency.

Spiral Coil Arrangement

The characteristic spiral design increases surface area by 30-50% compared to equivalent straight tubes, while the curved flow path enhances turbulence and heat transfer.

Technical Specifications and Design Parameters

Helical thermal oil coils are manufactured to precise specifications tailored to specific application requirements:

- Pipe Size Options:

- Outside Diameter: 60.3mm, 88.9mm, 101.6mm, 114.3mm, 127mm, 133mm, 141.3mm, 152mm, 168.3mm, 219.1mm, 273.1mm

- Wall Thickness: Customized based on pressure and temperature requirements

- Geometric Parameters:

- Bending diameter and radius

- Pipe spacing and pitch optimization

- Center-to-center and end-to-end height specifications

- Number of turns and coil orientation

- Configuration Options:

- Single pipe coils for standard applications

- Double pipe arrangements for increased capacity

- Triple and quadruple pipe configurations for high-demand systems

Manufacturing Process of Helical Coils

The production of high-quality helical thermal oil coils involves a meticulous multi-stage manufacturing process:

1. Material Selection

High-quality seamless steel pipes (carbon steel or stainless steel) are selected based on temperature, pressure, and corrosion resistance requirements.

2. End Preparation

Pipe ends are precisely notched at 30° angles using specialized equipment to ensure perfect weld joint alignment and penetration.

3. Welding Process

Prepared pipes are welded end-to-end using qualified welding procedures to maintain structural integrity and pressure containment.

4. Coil Formation

The straight pipe assembly is fed into precision coil bending machines that form the helical shape according to design specifications.

5. Quality Assurance

Comprehensive inspection including dimensional verification, weld integrity testing, and alignment confirmation.

6. Structural Reinforcement

Strategic welding of steel plates between coil turns to prevent deformation during thermal expansion and extend service life.

Measurement Techniques for Helical Coils

Proper measurement is critical for installation, replacement, and performance optimization of helical thermal oil coils. This video demonstrates industry-standard measurement methodologies:

Measurement parameters include coil diameter, pitch distance, tube alignment, and overall dimensions to ensure compatibility with existing thermal oil heating systems.

Industrial Applications

Helical thermal oil coils serve critical functions across diverse industrial sectors:

- Petroleum Refining: Heating crude oil and process streams in distillation columns and heat exchangers

- Chemical Production: Maintaining precise temperatures in reactors, evaporators, and distillation units

- Food Processing: Providing indirect heating for cooking oils, chocolate tempering, and sterilization processes

- Plastic Manufacturing: Heating polymer melts and maintaining temperature in extrusion and molding equipment

- Metal Processing: Heat treatment applications including annealing, tempering, and stress relieving

- Textile Industry: Heating dye baths and finishing chemicals in textile manufacturing processes

- Pharmaceuticals: Maintaining precise temperatures in reaction vessels and drying equipment

- Renewable Energy: Thermal energy storage systems and biomass processing applications

Performance Advantages

Helical thermal oil coils offer significant benefits over alternative heat exchanger designs:

Enhanced Heat Transfer

The spiral configuration creates turbulent flow that improves heat transfer coefficients by 25-40% compared to straight tubes.

Compact Design

Higher surface-area-to-volume ratio allows for more compact heat exchanger designs, saving valuable floor space.

Reduced Thermal Stress

The helical shape naturally accommodates thermal expansion, minimizing stress concentrations and extending service life.

Lower Fouling Tendency

Turbulent flow conditions reduce sediment deposition and fouling, maintaining efficiency over extended operational periods.

Operational Safety

Closed-loop design eliminates pressure-related risks associated with steam systems while operating at lower pressures.

Energy Efficiency

Superior heat transfer characteristics translate to reduced fuel consumption and lower operating costs.

Helical Thermal Oil Coil

Helical thermal oil coils represent a sophisticated engineering solution for industrial heating applications, combining exceptional heat transfer efficiency with robust construction and operational safety. Their unique spiral design maximizes surface area while inducing beneficial flow patterns that enhance thermal performance. With applications spanning multiple industries and the ability to operate at high temperatures with minimal pressure, these coils continue to be the preferred choice for efficient, reliable thermal oil heating systems.

Proper design, manufacturing, and maintenance of helical thermal oil coils are essential for optimizing performance, ensuring operational safety, and extending equipment service life in demanding industrial environments.