Applications of Finned Pipes

2023-11-01Leave a message

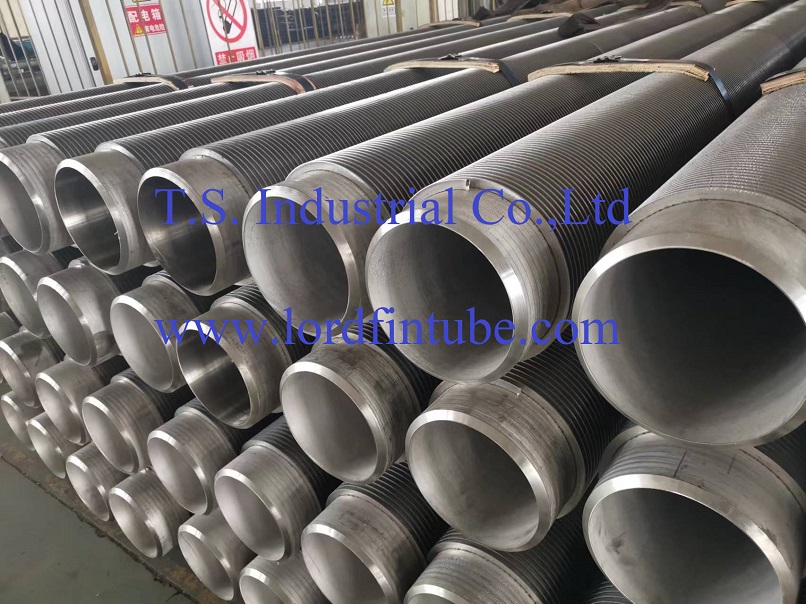

Applications of Finned Pipe in Air Preheaters

Finned Pipes Used in Air Preheaters:

The application involves absorbing waste heat from flue gases to heat the combustion air, thereby reducing fuel consumption and improving combustion conditions to achieve energy savings. It can also absorb waste heat from flue gases to heat other gas media, such as natural gas.

Advantages of Finned Pipe Air Preheater Equipment:

High heat transfer efficiency as it involves gas-to-gas heat exchange with finned tubes on both sides, which is 5-8 times more efficient than a regular air preheater.

Flue gas heat exchange outside the tubes is advantageous for ash removal.

Each heat tube is an independent heat transfer component, making it easy to disassemble and allowing for free expansion.

Wall temperature can be adjusted through design to avoid dew point corrosion.

Structural Types:

There are two common structural types: vertical placement of heat tubes with counter-flow of flue gas and air, as shown in Figure 1, and inclined placement of heat tubes with counter-flow of flue gas and air in the vertical direction.

Finned Pipes Used in Economizers

Usage in Economizers:

This involves absorbing heat from flue gases to heat feedwater, and the heated water can return to the boiler (as an economizer) or be used separately (as a water heater) to increase energy utilization and achieve energy savings.

Advantages of Finned Pipe Economizer Equipment:

Finned tubes on the flue gas side and smooth tubes on the water side result in high heat transfer efficiency.

Proper design can increase wall temperature to avoid dew point corrosion.

It effectively prevents the mixing of cold and hot fluids due to tube wall damage.

Structural Types:

Based on different methods of heating on the water side, there are two common structural types: integral heating tank (often using vertically placed heat tubes) and convection heating tank (often using inclined heat tube placement).

Finned Pipes Used in Waste Heat Boilers (Evaporators)

Usage in Waste Heat Boilers:

This application uses heat pipes as heat transfer elements to absorb high-temperature waste heat from flue gases to generate steam. The produced steam can be merged into a steam pipeline (meeting pipeline pressure requirements) or used for power generation (for large steam quantities and stable heat sources). This is a popular form of waste heat utilization for steel mills, petrochemical plants, and industrial furnaces.

Advantages of Finned Pipe Waste Heat Boiler Equipment:

Each heat pipe is an independent heat transfer unit, allowing for design based on different temperature levels.

Easy-to-disassemble heat pipe structures can be chosen as needed for convenient maintenance and installation.

Heat pipes completely isolate the heat source and cold source, preventing the mixing of cold and hot fluids.

Flue gas heat exchange occurs outside the tubes, making ash removal easy.

Structural Types:

There are two structural types: direct boiling within the steam drum, where the cooling section of the heat pipe extends directly into the steam drum to generate boiling, and boiling within a jacket, where the cooling section of the heat pipe is surrounded by a water jacket, causing water inside the jacket to boil in a flowing state, with the resulting steam merging into the steam drum.