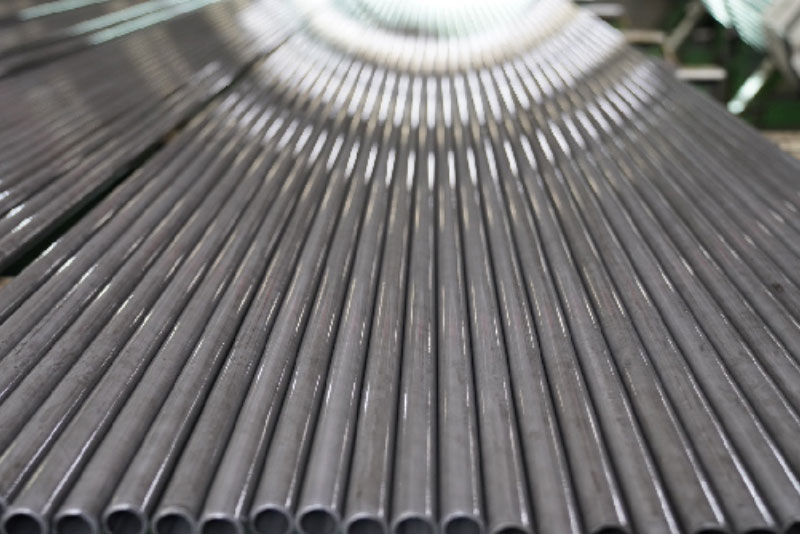

ASTM A178 Boiler Tube|ASTM A178 Tubing

|

Element % |

ASTM A178 Gr A / SA178A |

ASTM A178 Gr C / SA178C |

ASTM A178 Gr D / SA178D |

|

Low carbon steel |

Medium Carbon Steel |

Manganese Steel |

|

|

C |

0.06-0.18 |

0.35 Max |

0.27 Max |

|

Mn |

0.27-0.63 |

0.80 Max |

1.00-1.50 |

|

P |

0.035 |

0.035 |

0.03 |

|

S |

0.035 |

0.035 |

0.015 |

|

Si |

... |

... |

0.10 Min. |

|

Item |

ASTM A178 Gr.A / SA178A |

ASTM A178 Gr.C / SA178C |

ASTM A178 Gr.D / SA178D |

|

Tensile strength, min, ksi [MPa] |

47[325] |

60[415] |

70[485] |

|

Yield strength, min, ksi [MPa] |

26[180] |

37[255] |

40[275] |

|

Elongation in 2 in. or 50mm, min, % |

35 |

30 |

30 |

|

For longitudinal strip tests a deduction for |

1.50A |

1.50A |

1.50A |

|

Each1⁄32-in[0.8mm] decrease in wall thickness below 5⁄16in. [8mm] |

|||

|

From the basic minimum elongation of the following percentage points shall be made |

|||

|

Outside Diameter tolerance |

Wall thickness tolerance |

||

|

OD < 50 |

±0.05mm |

S < 4mm |

±12.5% |

|

OD > 50 |

±1% |

4--20mm |

-120 |

|

|

|

S≧20mm |

±12.5% |

ASTM A178 Condenser steel tube