ASTM B338 Titanium Alloy Tubes

ASTM B338 is Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers

1. ASTM B338 Scope

1.1 This specification covers the requirements for 28 grades of titanium and titanium alloy tubing intended for surface condensers, evaporators, and heat exchangers, as follows:

1.1.1 Grade 1—UNS R50250. Unalloyed titanium,

1.1.2 Grade 2—UNS R50400. Unalloyed titanium,

1.1.2.1 Grade 2H—UNS R50400. Unalloyed titanium (Grade 2 with 58 ksi (400 MPa) minimum UTS),

1.1.3 Grade 3—UNS R50550. Unalloyed titanium,

1.1.4 Grade 7—UNS R52400. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.4.1 Grade 7H—UNS R52400. Unalloyed titanium plus 0.12 to 0.25 % palladium (Grade 7 with 58 ksi (400 MPa) minimum UTS),

1.1.5 Grade 9—UNS R56320. Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.6 Grade 11—UNS R52250. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.7 Grade 12—UNS R53400. Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.8 Grade 13—UNS R53413. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.9 Grade 14—UNS R53414. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.10 Grade 15—UNS R53415. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.11 Grade 16—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.11.1 Grade 16H—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium (Grade 16 with 58 ksi (400 MPa) minimum UTS),1.1.12 Grade 17—UNS R52252. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.13 Grade 18—UNS R56322. Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.04 to 0.08 % palladium,

1.1.14 Grade 26—UNS R52404. Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.14.1 Grade 26H—UNS R52404. Unalloyed titanium plus 0.08 to 0.14 % ruthenium (Grade 26 with 58 ksi (400

MPa) minimum UTS),

1.1.15 Grade 27—UNS R52254. Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.16 Grade 28—UNS R56323. Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.08 to 0.14 % ruthenium,

1.1.17 Grade 30—UNS R53530. Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.18 Grade 31—UNS R53532. Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.19 Grade 33—UNS R53442. Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.20 Grade 34—UNS R53445. Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.21 Grade 35—UNS R56340. Titanium alloy (4.5 % aluminum, 2 % molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 % silicon),

1.1.22 Grade 36—UNS R58450. Titanium alloy (45 % niobium),

1.1.23 Grade 37—UNS R52815. Titanium alloy (1.5 % aluminum),

1.1.24 Grade 38—UNS R54250. Titanium alloy (4 % aluminum, 2.5 % vanadium, 1.5 % iron), and

1.1.25 Grade 39—UNS R53390. Titanium alloy (0.25 % iron, 0.4 % silicon).conversions to SI units that are provided for information only and are not considered standard.

2. ASTM B338 Referenced Documents

2.1 ASTM Standards: 3

A370 Test Methods and Definitions for Mechanical Testing of Steel Products E8 Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E1409 Test Method for Determination of Oxygen and Nitrogen in Titanium and Titanium Alloys by Inert Gas Fusion

E1447 Test Method for Determination of Hydrogen in Titanium and Titanium Alloys by Inert Gas Fusion Thermal

Conductivity/Infrared Detection Method

E1941 Test Method for Determination of Carbon in Refractory and Reactive Metals and TheirAlloys by Combustion

Analysis

E2371 Test Method for Analysis of Titanium and Titanium Alloys by Direct Current Plasma and Inductively Coupled

Plasma Atomic Emission Spectrometry (Performance Based Test Methodology)

E2626 Guide for Spectrometric Analysis of Reactive and Refractory Metals

3. ASTM B338 Terminology

3.1 Lot Definitions:

3.1.1 castings, a lot shall consist ofall castings produced from the same pour.

3.1.2 ingot, no definition required.

3.1.3 rounds, flats, tubes, and wrought powder metallurgical products (single definition, common to nuclear and non nuclear standards), n—a lot shall consist of a material of the same size, shape, condition, and finish produced from the same ingot or powder blend by the same reduction schedule and the same heat treatment parameters. Unless otherwise agreed between manufacturer and purchaser, a lot shall be limited to the product of an 8 h period for final continuous anneal, or to a single furnace load for final batch anneal.

3.1.4 sponge, n—a lot shall consist of a single blend produced at one time.

3.1.5 weld fittings, n—definition is to be mutually agreed upon between manufacturer and the purchaser.

4. ASTM B338 Ordering Information

4.1 Orders for material to this specification shall include the following information, as required:

4.1.1 Quantity,

4.1.2 Grade number (Section 1),

4.1.3 Diameter and wall thickness (Note 2) (Section 12),

4.1.4 Length (Section 12),

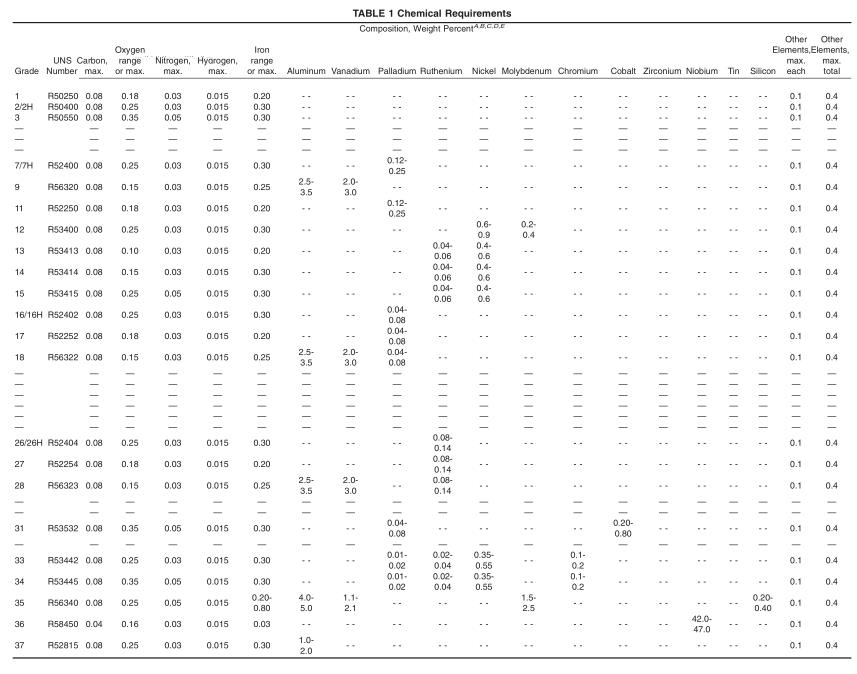

4.1.5 Method ofmanufacture and finish (Sections 5 and 13),4.1.6 Restrictive chemistry, if desired (Section 6 and Table 1),

4.1.7 Product analysis, if desired (Section 7 and Table 2),

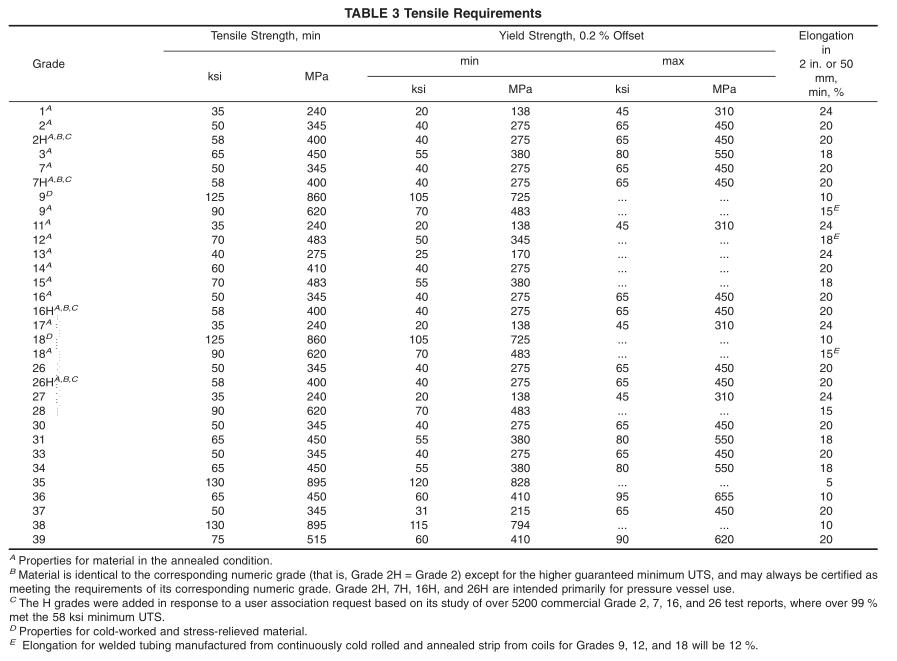

4.1.8 Special mechanical properties, if desired (Section 8 and Table 3),

4.1.9 Nondestructive tests (Section 11),

4.1.10 Packaging (Section 23),

4.1.11 Inspection (Section 17), and

4.1.12 Certification (Section 21).

Note 2—Tube is available to specified outside diameter and wall thickness. Average OD and wall are the standard. Maximum or minimum OD or wall should be stated.

5. ASTM B338 Materials and Manufacture

5.1 Seamless tube shall be made from hollow billet by any cold reducing or cold drawing process that will yield a product meeting the requirements ofthis specification. Seamless tube is produced with a continuous periphery in all stages of manufacturing operations.

5.2 Welded tube shall be made from annealed, flat-rolled product by an automatic arc-welding process or other method of welding that will yield a product meeting the tensile requirements found in Table 3 of this specification. Welded tubing shall be heat treated by at least a stress relief after forming and welding. Use of filler material is not permitted.

5.3 Welded/cold worked tube (WCS) shall be made from welded tube manufactured as specified in 5.2. The welded tube shall be sufficiently cold worked to final size in order to transform the cast weld microstructure into a typical equiaxed microstructure in the weld upon subsequent heat treatment. The product shall meet the requirements for seamless tube of this specification.

5.4 Grades 9, 18 and 28, which, at the option of the purchaser, can be furnished in either the annealed or the cold worked and stress relieved condition, defined as at a minimum temperature of 600°F (316°C) for not less than 30 min.

6. ASTM B338 Chemical Requirements

6.1 The titanium shall conform to the chemical requirements prescribed in Table 1.

6.1.1 The elements listed in Table 1 are intentional alloy additions or elements that are inherent to the manufacture of titanium sponge, ingot, or mill product.

6.1.2 Elements intentionally added to the melt must be identified, analyzed, and reported in the chemical analysis.

6.2 When agreed upon by the producer and the purchaser and requested by the purchaser in the written purchase order, chemical analysis shall be completed for specific residual elements not listed in this specification.

7. ASTM B338 Product Analysis

7.1 When requested by the purchaser and stated in the purchase order, product analysis for any elements listed in Table 1 shall be made on the completed product.

7.1.1 Elements other than those listed in Table 1 are deemed to be capable ofoccurring in the grades listed in Table 1 by, and only by way of, unregulated or unanalyzed scrap additions to the ingot melt. Therefore, product analysis for elements not listed in Table 1 shall not be required unless specified and shall be considered to be in excess of the intent of this specification.

7.2 Product analysis tolerances, listed in Table 2, do not broaden the specified heat analysis requirements, but cover variations between different laboratories in the measurement of chemical content. The manufacturer shall not ship the finished product that is outside the limits specified in Table 1 for the applicable grade.

8. ASTM B338 Tensile Requirements

8.1 The room temperature tensile properties of the tube in the condition normally supplied shall conform to the requirements prescribed in Table 3. Mechanical properties for conditions other than those given in this table may be established by agreement between the manufacturer and the purchaser. (See Test Methods E8.)

9. ASTM B338 Flattening Test

9.1 Tubing shall withstand, without cracking, flattening under a load applied gradually at room temperature until the distance between the load platens is not more than H in.

10. ASTM B338 Flaring Test

10.1 For tube 3 1 ⁄ 2 in. (88 mm) in outside diameter and smaller, and 0.134 in. (3.4 mm) in wall thickness and thinner, a section of tube approximately 4 in. (102 mm) in length shall withstand being flared with a tool having a 60° included angle until the tube at the mouth of the flare has been expanded in accordance with Table 4. The flared end shall show no cracking or rupture visible to the unaided eye. Flaring tests on larger diameter tube or tubing outside the range of Table 4 shall be as agreed upon between the manufacturer and the purchaser.

11. ASTM B338 Keywords

8.1 seamless titanium tubing; titanium tube; titanium alloy tube; welded/cold worked titanium alloy tube tubing; welded titanium alloy tubing.

Standard ASTM B338/B338M download Links