Products Description

What is a Corrugated Furnace Tube?

A corrugated furnace is a critical component in oil-fired boilers, serving as an indispensable element. Acting as the boilers combustion chamber, it is directly exposed to radiation from high-temperature flames and scouring by hot flue gases. Its axial expansion and contraction capabilities mitigate thermal stresses generated in the boiler shell, tube sheets, and the furnace itself. More importantly, this design alleviates stress concentrations caused by furnace elongation at the junction between the furnace and tube sheets.

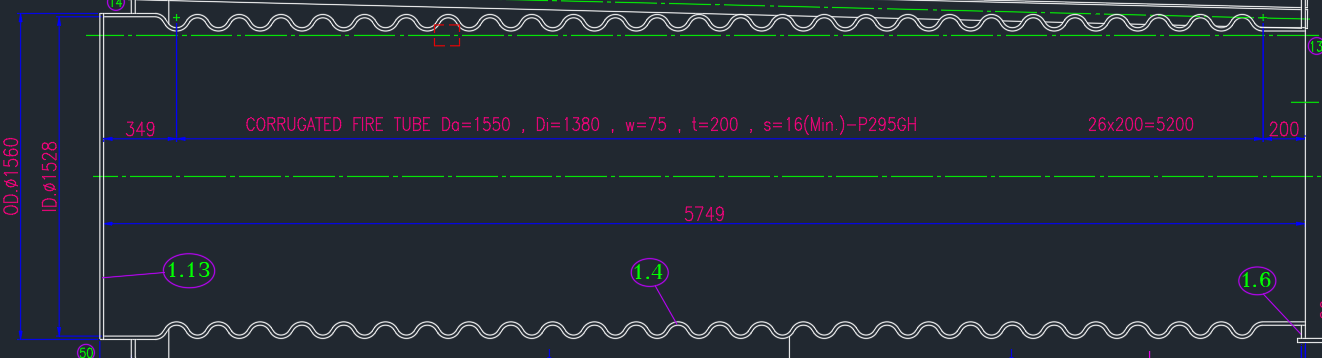

Corrugated Furnace Tube Structure Description

The corrugated furnace is a cylindrical metal shell with annular corrugations on its outer wall. Its diameter typically ranges from 0.8 to 2 meters, and its length can extend to several meters.

Functions of the Corrugated Fire Tube Design

Enhance flue gas turbulence Increase radiative heat transfer area Improve structural stiffness Mitigate thermal expansion stress

Corrugated Fire Tube Manufacturing Process

The corrugated furnace is generally formed by spinning process 1. Cylinder Rolling A cylindrical shell is rolled to the maximum diameter specified in the design. Post-rolling operations: Welding and circularity correction. 2. Spinning Forming Setup: Mount the pre-formed cylinder on a spinning machine. Rotation: The cylinder rotates slowly (driven by a motor via a gearbox and chuck). Heating & Forming: Heat the target section to >600°C using diesel flames. Apply compressed air to press a wave-shaped rolling die against the rotating cylinder. Repeat rotational extrusion until the corrugated profile meets specifications. 3. Stress Relief Annealing Purpose: Eliminate residual stresses from welding and spinning to ensure dimensional stability. Procedure: Heat treatment before assembly welding with front/rear tube sheets and smoke chambers.

Corrugated Fire Tube Material Options

Stainless Steel: SA304, SA316L...For corrosive environments Carbon Steel: ASTM SA 516 Gr60, SA516 Gr70, Cost-effective choice for general industrial applications

Advantages of Boiler Corrugated Furnace Tube

1.High Strength The boiler furnace is constructed from pressure vessel-grade steel, offering exceptional strength and pressure resistance to withstand high-temperature, high-pressure operating environments. 2.Superior Corrosion Resistance The interior of the boiler furnace undergoes specialized treatment, providing excellent corrosion resistance. It effectively resists degradation under high-temperature, high-pressure conditions, significantly extending the boiler’s service life. 3.Excellent Thermal Conductivity The boiler furnace exhibits outstanding heat transfer performance, efficiently transferring thermal energy from combustion to the working medium, thereby enhancing the boiler’s thermal efficiency. 4.Rational Structural Design The furnace’s well-engineered structure ensures stable combustion and uniform heat distribution, optimizing both thermal efficiency and operational safety. 5.Ease of Maintenance The furnace’s simplified design facilitates easy maintenance and cleaning, reducing upkeep costs and minimizing labor intensity for personnel.

Corrugated Furnace Tube Applications

The corrugated furnace, leveraging its unique wave-like structure and superior performance, is widely used in industrial and civil applications requiring efficient and stable heat exchange, Chemical Industry, Paper Manufacturing, Biopharmaceuticals, Energy Sector.