Products Description

What is boiler tube sheet?

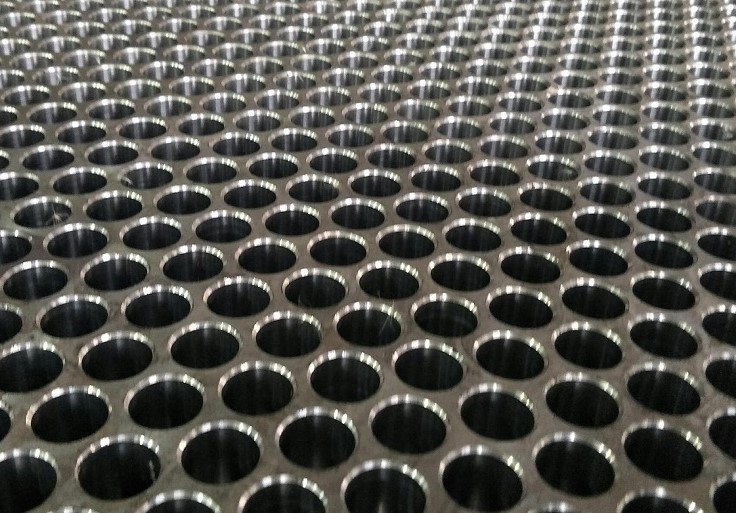

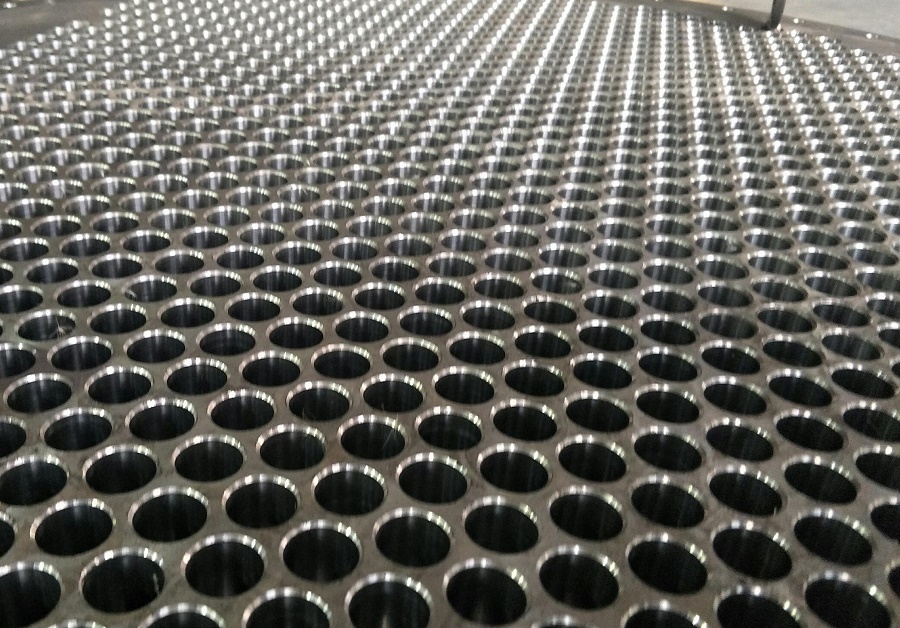

Boiler tube sheets are typically made of materials that are strong, durable, and resistant to heat and corrosion. A boiler tube sheet is a plate, usually made of metal, that forms a part of the main body of a boiler. It is used to support the tubes that carry water or steam through the boiler and is typically located near the top or bottom of the boiler. The tube sheet is an important component of the boiler, as it helps to ensure that the tubes are held securely in place and that there are no leaks between the tubes and the surrounding structure.

What kind of material use for boiler tube sheet?

A boiler tube sheet is a component of a boiler or heat exchanger that acts as a support and sealing mechanism for the boiler tubes. It is a flat, circular plate that is typically made of a durable and heat-resistant material. The tube sheet contains holes or bores through which the boiler tubes are inserted and secured. Common materials used include carbon steel, stainless steel, and various alloys such as Inconel and Hastelloy. The choice of material depends on factors such as the operating conditions of the boiler, the type of fuel being burned, and the expected lifespan of the equipment.

The choice of material for the boiler tube sheet depends on various factors, including the operating temperature, pressure, and the type of fluid or gas being processed in the boiler. Commonly used material grades for boiler tube sheets include:

1. Carbon Steel (ASTM A516 Gr.70, A285 Gr.C): Carbon steel is a widely used material for boiler tube sheets due to its good mechanical properties and relatively low cost.

2. Stainless Steel (ASTM A240, A182): Stainless steel is chosen for applications requiring high corrosion resistance or when the fluid being processed is corrosive in nature. Grades such as 304, 316, and 321 are commonly used.

3. Alloy Steel (ASTM A387, A213): Alloy steel provides excellent strength and resistance to high temperatures and pressure. Grades such as P11, P22, and P91 are commonly used in boiler tube sheets for elevated temperature applications.

The main size of boiler tube sheet?

The sizes of boiler tube sheets can vary depending on the specific design and requirements of the boiler or heat exchanger. Typically, tube sheets have diameters ranging from a few inches to several feet. The number and arrangement of tube holes also vary, depending on the design and heat transfer requirements. Its important to note that the actual sizes and specifications of boiler tube sheets are determined by engineering calculations and standards specific to each application.