ASTM B111 C12200 Evaporator Tube

C12200 Evaporator Tube

As heat exchange equipment experts, we delve into the technical specifics of C12200 evaporator tubes, a critical component in refrigeration and air conditioning systems. This article provides original, in-depth content to help engineers, manufacturers, and technicians understand and optimize the use of these tubes.

C12200 Evaporator Tube Composition

C12200 is a phosphorus-deoxidized copper alloy with high purity, offering exceptional thermal conductivity and corrosion resistance. The table below details its chemical composition, which directly influences performance in evaporator applications.

| Element | Composition (%) |

|---|---|

| Copper (Cu) | 99.90 min |

| Phosphorus (P) | 0.015 - 0.040 |

| Arsenic (As) | 0.04 - 0.06 |

Table 1: C12200 copper alloy chemical composition, ensuring high thermal efficiency and durability.

C12200 Evaporator Tube Properties

The unique properties of C12200 make it ideal for evaporator tubes. Key characteristics include:

- Thermal Conductivity: Excellent heat transfer rates, crucial for efficient evaporation in cooling systems.

- Corrosion Resistance: Withstands moisture and refrigerants, reducing maintenance needs.

- Mechanical Strength: Good ductility and fatigue resistance for long-term operation.

- Weldability: Easily joined using standard techniques, facilitating installation.

C12200 Evaporator Tube Applications

These tubes are widely used in various cooling systems, from residential air conditioning systems to industrial refrigeration. Applications include:

- HVAC evaporators and condensers

- Commercial refrigeration units (e.g., supermarkets, cold storage)

- Industrial heat exchangers in chemical processing

- Renewable energy systems like geothermal heat pumps

C12200 Evaporator Tube Performance Comparison

To highlight advantages, compare C12200 with other common evaporator tube materials. The table below summarizes key metrics.

| Material | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Cost Index | Best For |

|---|---|---|---|---|

| C12200 Copper Alloy | 390 | Excellent | 1.0 (Reference) | High-efficiency HVAC, industrial cooling |

| C10200 Oxygen-Free Copper | 401 | Good | 0.9 | Basic refrigeration, low-moisture environments |

| Aluminum Alloy | 237 | Moderate | 0.7 | Lightweight systems, cost-sensitive applications |

| Stainless Steel 316 | 16 | Outstanding | 2.5 | Aggressive chemical environments |

Table 2: Performance comparison of evaporator tube materials. C12200 balances high thermal conductivity with corrosion resistance.

C12200 Evaporator Tube Design Considerations

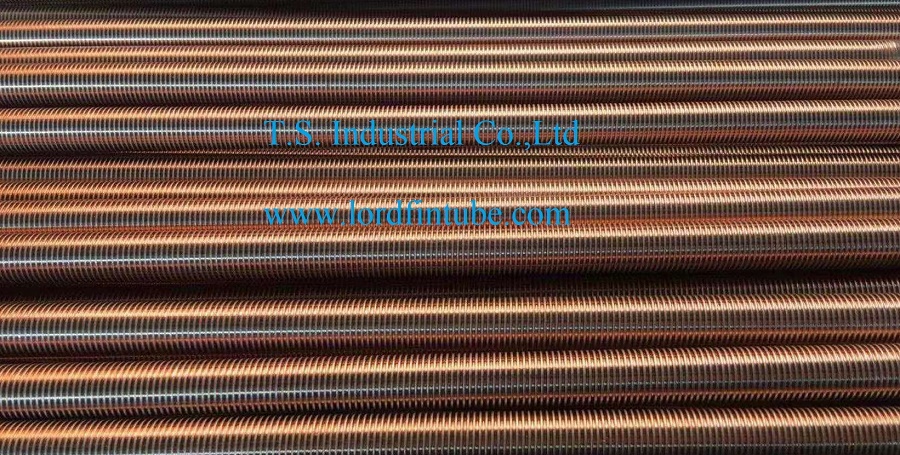

When designing with C12200 evaporator tubes, consider factors like tube diameter, wall thickness, and fin configuration. For enhanced performance, pairing with evaporator tubes with fins can increase surface area and heat transfer efficiency.

Figure 1: C12200 evaporator tubes integrated into a finned-tube heat exchanger for optimal cooling.

C12200 Evaporator Tube Maintenance and Longevity

Proper maintenance extends tube life. Regular inspections for scaling or corrosion, using compatible refrigerants, and ensuring clean systems can prevent failures. C12200s inherent resistance reduces downtime, supporting sustainable operations.

C12200 Evaporator Tube Selection

Select tubes based on system requirements. Use the guide below to match C12200 specifications to application needs.

| System Type | Recommended Tube Diameter (mm) | Wall Thickness (mm) | Key Benefit |

|---|---|---|---|

| Residential AC | 9.52 - 12.7 | 0.35 - 0.5 | Cost-effective efficiency |

| Commercial Refrigeration | 15.88 - 19.05 | 0.5 - 0.7 | Durability under cyclic loads |

| Industrial Chillers | 22.2 - 25.4 | 0.7 - 1.0 | High heat transfer for large scales |

Table 3: C12200 evaporator tube selection guide for optimized system design.

C12200 evaporator tubes are a premium choice for efficient and reliable heat exchange. By understanding their composition, properties, and applications, engineers can leverage these tubes for sustainable cooling solutions. For more details, explore our resource on C12200 Evaporator Tube technology.