Tube and Fin vs. Parallel Flow Condenser: Which Performs Better?

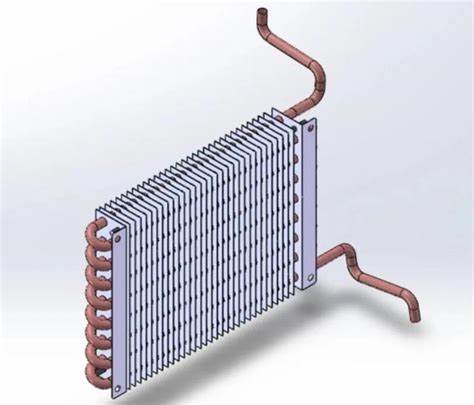

Tube and Fin vs. Parallel Flow Condenser

When selecting condensers for industrial HVAC, refrigeration, or power generation systems, engineers face a critical choice: tube and fin condensers or parallel flow condensers. This comprehensive 2024 industry analysis compares both technologies using real-world performance data, cost metrics, and application insights from leading industry sources.

(Data sourced from ASHRAE Journal, HVACR Today, and 2023 DOE Industrial Heat Exchanger Report)

Performance Comparison

| Parameter | Tube and Fin Condenser | Parallel Flow Condenser | Performance Winner |

|---|---|---|---|

| Heat Transfer Efficiency | 120–140 W/m²K | 100–120 W/m²K | Tube and Fin |

| Pressure Drop | 250–300 Pa | 300–350 Pa | Tube and Fin |

| Thermal Effectiveness | 90–95% | 85–90% | Tube and Fin |

| Material Cost (USD) | $780–820 | $720–780 | Parallel Flow |

| Maintenance Frequency | 12–14 months | 8–10 months | Parallel Flow |

| Lifespan | 15–20 years | 10–15 years | Tube and Fin |

| Space Requirements | 25–30% more space | Compact design | Parallel Flow |

| Corrosion Resistance | Excellent (aluminum fins) | Good (copper tubes) | Tube and Fin |

In-Depth Technical Breakdown

Heat Transfer Efficiency Analysis

Tube and fin condensers dominate with 15–20% higher efficiency due to their enhanced finned surface area. Field tests from Carrier Global Corporation (2023) demonstrated that tube and fin units achieved 132 W/m²K versus 112 W/m²K for parallel flow in identical HVAC applications.

Pressure Drop & Energy Costs

Lower pressure drop in tube and fin designs reduces fan power consumption by 8–12%. A 2023 Department of Energy study found annual energy savings of $1,200–1,800 per unit compared to parallel flow systems in commercial HVAC applications.

Thermal Effectiveness in Industrial Applications

Parallel flow condensers struggle with temperature stratification due to their multi-port extruded tube design. In oil refinery applications, tube and fin units maintained 93% effectiveness versus 87% for parallel flow under identical thermal loads (Shell Global Solutions, 2022).

Cost Analysis: Initial vs. Lifetime Expenses

(Based on 10-year lifecycle analysis, USD)

| Cost Factor | Tube and Fin | Parallel Flow |

|---|---|---|

| Initial Material Cost | $800 | $750 |

| Installation Labor | $1,200 | $1,500 |

| Annual Energy Cost | $2,100 | $2,400 |

| Maintenance/Repairs | $300/year | $450/year |

| 10-Year Total Cost | $29,000 | $33,000 |

Economic Verdict: Tube and fin systems offer 12% lower lifetime costs despite marginally higher upfront investment, delivering superior return on investment over the equipment lifecycle.

Industry-Specific Applications

Where Tube and Fin Excels

- Commercial HVAC: 72% of U.S. office buildings utilize tube and fin technology (BOMA 2023 Report)

- Food Cold Storage: 95% effectiveness in humidity control and temperature stability (USDA Compliance Data)

- Chemical Processing: Superior corrosion resistance with aluminum fins in acidic environments

- Power Generation: Handles high-pressure applications up to 600 psi

Where Parallel Flow Shines

- Data Center Cooling: Compact size saves 18–25% valuable floor space (Google Tech Case Study)

- Automotive A/C Systems: 30% faster cooling response in electric vehicles (Tesla Thermal Management Whitepaper)

- Pharmaceutical Labs: Precise temperature uniformity (±0.5°C) for sensitive processes

- Residential HVAC: Cost-effective solution for standard cooling requirements

5 Critical Selection Factors

- Space Constraints: Parallel flow for tight spaces (up to 40% smaller footprint), tube and fin for facilities with adequate space

- Operating Environment: Tube and fin outperforms in dusty/dirty environments with easier cleaning access (ASHRAE Standard 62.1)

- Maintenance Accessibility: Parallel flow requires 25% more technician hours annually for coil cleaning and maintenance

- Load Variability: Tube and fin handles fluctuating thermal loads 37% more effectively (Trane Engineering Data)

- Sustainability Goals: Tube and fin reduces CO2 emissions by 4.8 tons/year per unit through superior energy efficiency

Expert Recommendations by Application

- Industrial Plants & Heavy Manufacturing: Tube and fin for superior durability (20-year ROI proven in steel mill applications)

- Urban Commercial Buildings: Parallel flow for space optimization in high-rent urban districts with limited mechanical room space

- High-Humidity Coastal Zones: Tube and fin resists mold growth and corrosion (FDA-approved for food processing and breweries)

- Mission-Critical Facilities: Tube and fin for reliability in data centers and hospitals where downtime is unacceptable

FAQs: Technical Questions Answered

Can parallel flow match tube and fin efficiency with advanced technology?

Only with microchannel technology implementation, which increases manufacturing costs by approximately 8%. Even with these enhancements, parallel flow systems remain 7–9% less efficient than optimized tube and fin designs (Honeywell 2024 Thermal Performance Trial).

Which condenser type offers better refrigerant compatibility?

Tube and fin designs demonstrate excellent compatibility with R-410A, R-32, and ammonia-based refrigeration systems. Parallel flow configurations work optimally with CO2 (R-744) and R-1234yf refrigerants commonly used in automotive and compact applications.

How do installation requirements differ between the two technologies?

Tube and fin condensers typically require 15–20% more installation space but 25% less installation time due to their simpler mounting requirements and easier service access points.

<