Manufacturing Process of Condenser Finned Tubes

2023-10-28Leave a message

Manufacturing Process of Condenser Finned Tubes

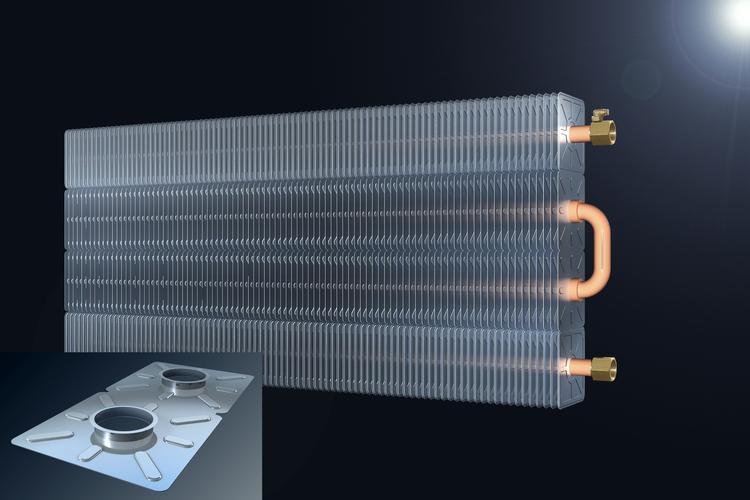

Condenser finned tubes are a common type of heat exchanger widely used in the fields of air conditioning, cold storage, refrigerated vehicles, and more. The manufacturing process typically involves the following steps:

1. Condenser finned tubes Fin Production:

Fins are a crucial component of condenser finned tubes, as they serve to increase the heat exchange surface area and enhance heat exchange efficiency. Fins are typically made from aluminum or copper sheets and are formed through mold stamping. Subsequent processes include cutting, bending, and other fabrication techniques to obtain fins with specific shapes and dimensions.

2. Condenser finned tubes Tube Production:

Tubes are another essential component of condenser finned tubes, responsible for conveying refrigerants or cooling agents to facilitate the heat exchange process. Copper or aluminum tubes are commonly used and are shaped through processes such as stretching and rolling to achieve the desired diameter and length.

3. Assembly of Fins and Tubes:

The pre-made fins and tubes are assembled using methods such as mechanical or manual tube winding. Fins are wrapped around the tubes, creating the finned tube. During the winding process, attention is paid to the spacing and angles of the fins to ensure optimal heat exchange efficiency and fluid flow resistance.

4. Condenser finned tubes Welding:

The assembled finned tubes are welded together, typically using methods like argon arc welding or resistance welding, to securely connect the fins and tubes. During the welding process, temperature and time are carefully controlled to ensure welding quality and the service life of the finned tubes.

5. Condenser finned tubes Surface Treatment:

The welded finned tubes undergo surface treatment, which often involves methods such as spray painting or electrophoretic coating. A layer of anti-corrosive or protective paint is applied to the surface of the finned tubes to prevent corrosion and oxidation.

The manufacturing process of condenser finned tubes includes fin production, tube production, assembly, welding, and surface treatment, with each step requiring strict control of process parameters and quality requirements to guarantee the performance and longevity of the finned tubes.