ASTM B171/B171M Tube Sheet Copper-Alloy Plate and Sheet

ASTM B171/B171M Tube Sheet Standard Specification for Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers.

ASTM B171/B171M Tube Sheet Scope:

ASTM B171/B171M Tube Sheet establishes the requirements for copper-alloy plate, sheet, and circles cut from plate and sheet for pressure vessels, condensers, and heat exchangers. The following alloys are covered:

Copper Alloy Previously Used Designation

C36500 Leaded Muntz Metal

C44300 Admirality, Arsenical

C44400 Admirality, Antimonial

C44500 Admirality, Phosphorized

C46400 Naval Brass, Uninhibited

C46500 Naval Brass, Arsenical

C61300 Aluminum Bronze

C61400 Aluminum Bronze D

C63000 10 % Aluminum-Nickel Bronze

C63200 9 % Aluminum-Nickel Bronze

C70600 90-10 Copper Nickel

C70620 90-10 Copper Nickel -(modified for welding)

C71500 70-30 Copper Nickel

C71520 70-30 Copper Nickel-(modified for welding)

C72200

ASTM B171/B171M Tube Sheet Referenced Documents

2.1 ASTM Standards:

B248 Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled Bar

B248M Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled Bar (Metric)

B601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

B846 Terminology for Copper and Copper Alloys

E8/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E54 Test Methods for Chemical Analysis of Special Brasses and Bronzes (Withdrawn 2002) 4

E62 Test Methods for Chemical Analysis of Copper and CopperAlloys (Photometric Methods) (Withdrawn 2010) 4

E255 Practice for Sampling Copper and Copper Alloys for the Determination of Chemical Composition

E478 Test Methods for Chemical Analysis of Copper Alloys

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3. ASTM B171/B171M Tube Sheet Terminology

3.1 For definitions of terms related to copper and copper alloys, refer to Terminology B846.

4. ASTM B171/B171M Tube Sheet Ordering Information

4.1 Include the following information when placing orders for product under this specification, as applicable:

4.1.1 ASTM designation and year of issue,

4.1.2 Whether inch-pound or SI units are applicable (see1.2),

4.1.3 Copper Alloy UNS. No. (see Section 6, Table 1),

4.1.4 Whether the alloy ordered will be used in applications requiring it to be welded (see Table 1, footnotes B and C for UNS Nos. C61300 and C72200, respectively, and UNS Nos. C70620 and C71520 in place of UNS Nos. C70600 and C71500),

4.1.5 Whether plate is to be machined (see 9.1.3),

4.1.6 How tolerance is specified (Table 2 Footnote A)

4.1.7 Certification, if required (Section 17),

4.1.8 Weight (total for each size),

4.1.9 Mill test report, if required (Section 18),

4.1.10 Special marking, if required (Section 19), and

4.1.11 Whether 0.2 yield offset strength is required.

5. ASTM B171/B171M Tube Sheet Materials and Manufacture

5.1 Material—The material and manufacture shall be cast cake of the Copper Alloy UNS No. specified in the purchase order and shall be of such shape and soundness so as to be suitable for processing into the final product.

5.2 Manufacture—The product shall be manufactured by hot rolling or forging and finished by such cold working and annealing as may be necessary to achieve the required dimensions and properties.

6. ASTM B171/B171M Tube Sheet Chemical Composition

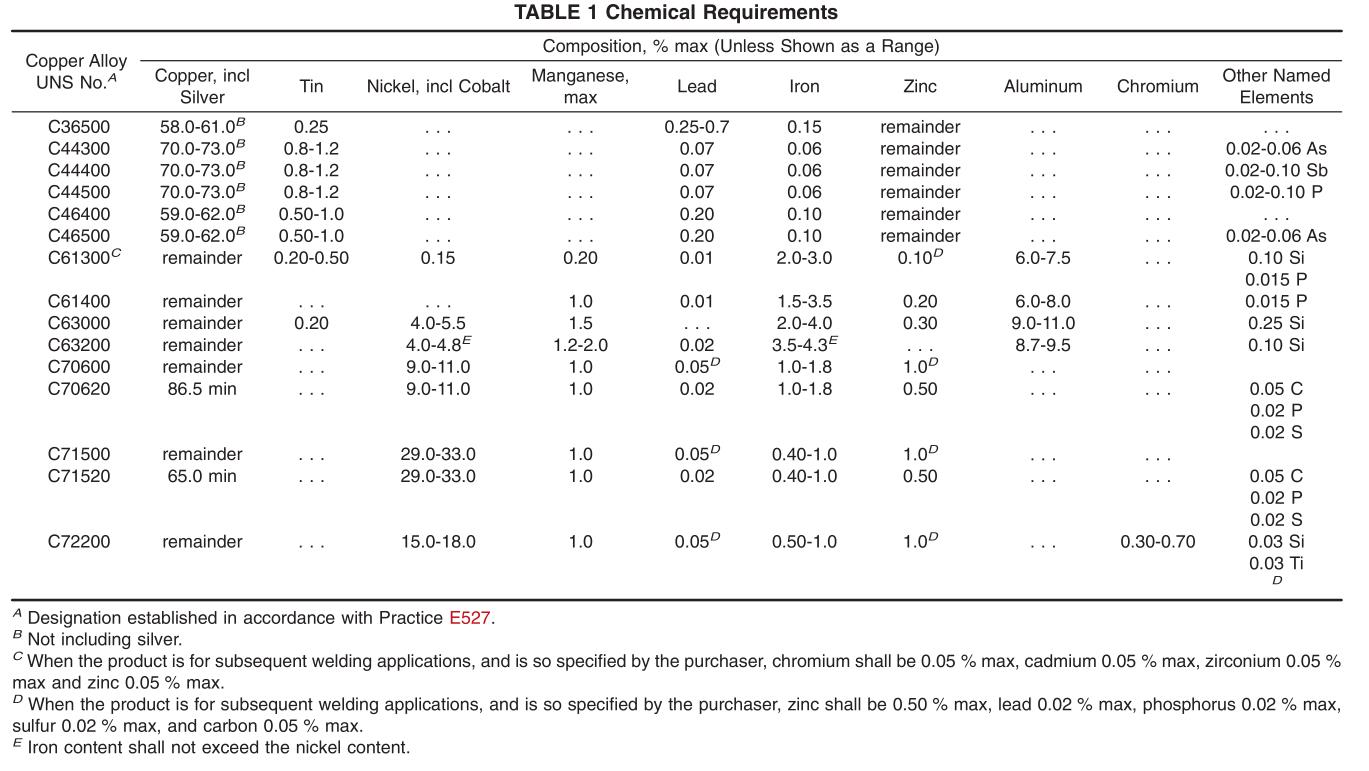

6.1 The materials shall conform to the chemical compositional requirements specified in Table 1 for the copper alloy UNS designations specified in the ordering information.

6.2 These composition limits do not preclude the presence of other elements. Limits for unnamed elements may be established by agreement between manufacturer or supplier and purchaser.

6.3 For the alloys listed below, depending on analytical methodology, either copper or zinc, respectively, may be taken as the difference between the sum of all the elements analyzed and 100 %. When all the elements

6.3.1 For the alloys listed below, copper may be taken as the difference between the sum of all the elements and 100 %. When all of the elements in Table 1 are analyzed, their sum

7. ASTM B171/B171M Tube Sheet Temper

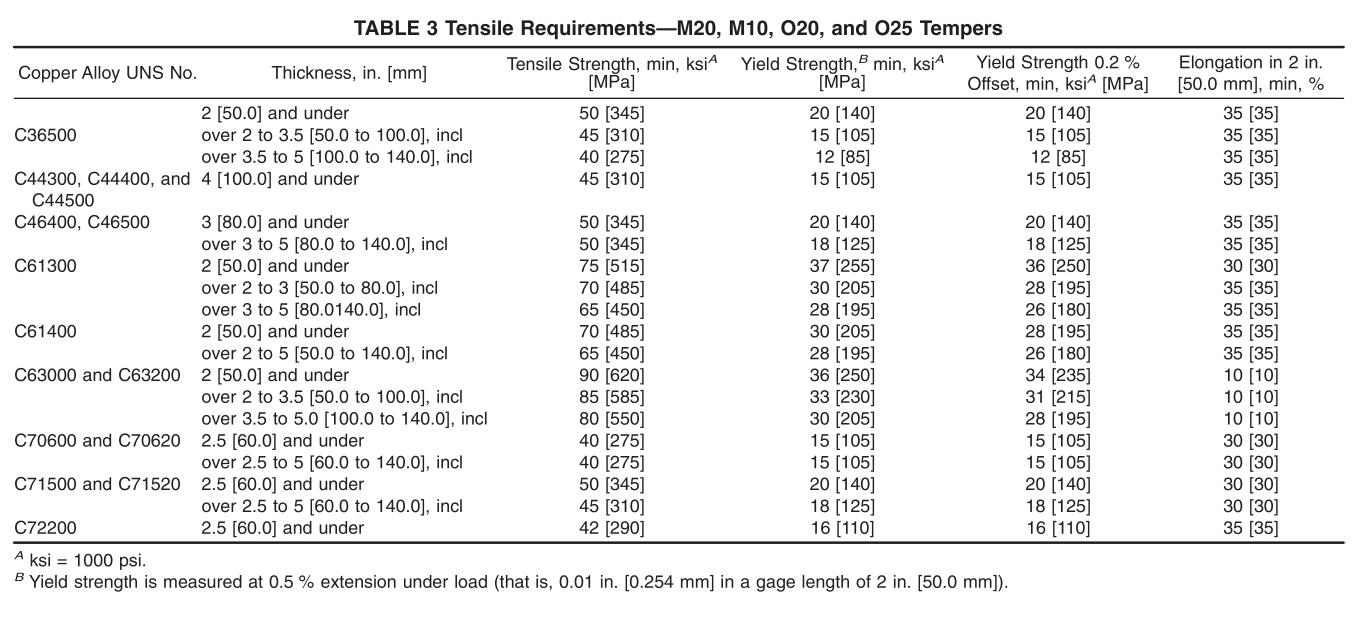

7.1 Tempers available under this specification, and as described in Classification B601, are As Hot Rolled (M20), Hot Rolled and Annealed (O25), Hot Forged and Annealed (O20),and As Hot Forged-Air Cooled (M10) as given in Table 3.

7.1.1 Products manufactured for ASME Boiler and Pressure Vessel Code applications must be certified to the O25 or O20 temper.

7.1.2 Products manufactured for other than ASME Boiler and Pressure Vessel Code applications may be produced in either the M20, M10, O20, or O25 temper.

8. ASTM B171/B171M Tube Sheet Mechanical Property Requirements

8.1 Tensile Strength Requirements :

8.1.1 Product furnished under this specification shall conform to the tensile property requirements prescribed in Table 3, when tested in accordance with Test Method E8/E8M.

9. ASTM B171/B171M Tube Sheet Dimensions, Mass, and Permissible Variations

9.1 Thickness:

9.1.1 The thickness tolerances for plates of Copper Alloy UNS Nos. C36500, C44300, C44400, C44500, C46400, and C46500 shall be as prescribed in Table 2.

9.1.2 The thickness tolerances for plates of Copper Alloy UNS Nos. C61300, C61400, C63000, C63200, C71500, C70620, C71520, and C72200 shall be 25 % greater than those prescribed in Table 2.

9.1.3 If plates are machined, the thickness tolerances shall apply to the machined portion only.

9.1.4 Closer thickness tolerances than those prescribed in Table 2 can be furnished by surface machining. This is a special product and is subject to agreement between the manufacturer and the purchaser. This special product shall apply only when specified by the purchaser in the contract or order.

9.1.5 Unless otherwise agreed to by the manufacturer and the purchaser, the thickness of plate to this specification shall be determined by measuring along the length of the plate up to a distance of 7 in. [180 mm] from the edge.

9.2 Diameters, Lengths, or Widths—The diameters, lengths,or widths of plates shall be not less than those specified. The diameters, lengths, or widths of plates may exceed thosespecified by the amounts shown in Table 4.

9.3 Flatness—The flatness tolerances of individual plates shall not exceed those prescribed in Table 5. The tolerances shown are the total permissible variations for plates as ordered, and do not apply to the 7-in. [180-mm] marginal area at the edge of the plate. Inspection for flatness shall be made by placing the plate on a flat surfaced table with the side marked “Straight Side” up, applying a 72-in. [2-m] straightedge when the size permits, or a shorter one equal to the dimensions to be inspected, and measuring the depth ofarc between the straight edge and the plate.

9.4 Plate and Sheet Lot Weight for Pressure Vessels—When plate or sheet of Copper Alloy UNS Nos. C70600, C70620,C71500, C71520, or C72200 are ordered for pressure vessels exclusively, the maximum lot weight restriction in Table 6 shall apply in addition to the thickness tolerance requirement of Table 2. The weight of each lot of five or more plates or sheets shall not exceed the nominal weight by more than the amount prescribed in Table 6. Plate and sheet of lots of less than five shall be governed solely by the thickness tolerances ofTable 2. For purposes of calculating weights, the densities used shall be as listed in Table 7.

10. ASTM B171/B171M Tube Sheet Workmanship, Finish, and Appearance

10.1 The product shall be free of defects, but blemishes of a nature that do not interfere with the intended application are acceptable.

11. ASTM B171/B171M Tube Sheet Sampling

11.1 The lot size, portion size, and selection of pieces shall be as follows:

11.1.1 Lot Size—10 000 lbs [4550 kg] or less material of the same mill form, alloy, temper, and thickness, subject to inspection at one time.

11.1.2 Portion Size—Four individual sample pieces shall be selected as representative of each lot. If the lot consists of less than four pieces, samples shall be selected so as to be representative of each piece.

11.2 Chemical Analysis—A sample for chemical analysis shall be taken and prepared in accordance with Practice E255. Drillings, millings, and so forth, shall be taken in approximately equal weight from each ofthe sample pieces selected in accordance with 11.1.2 and combined into one composite sample. The minimum weight of the composite sample that is to be divided into three equal parts shall be 150 g.

11.2.1 Instead of sampling in accordance with Practice E255, the manufacturer shall have the option of determining conformance to chemical composition by analyzing samples taken at the time castings are poured or samples taken from the semi-finished product. If the manufacturer determines the chemical composition of the material during the course of manufacture, he shall not be required to sample and analyze the finished product. The number of samples taken for determination of chemical composition shall be as follows:

11.2.1.1 When samples are taken at the time the castings are poured, at least one sample shall be taken for each group of castings poured simultaneously from the same source of molten metal.

11.2.1.2 When samples are taken from the semi-finished product, a sample shall be taken to represent each 10 000 lbs [4550 kg] or fraction thereof, except that not more than one sample shall be required per piece.

11.2.2 Because of the discontinuous nature of the processing ofcastings into wrought products, it is not practical to keep specific casting analysis identified with a specific quantity of finished material.

11.2.3 In the event that heat identification or traceability is required, the purchaser shall specify the details desired.

12. ASTM B171/B171M Tube Sheet Number of Tests and Retests

12.1 Tests:

12.1.1 Chemical Analysis—Chemical composition shall be determined as the per element mean ofresults from at least two replicate analyses of the sample(s), and the results of each replication shall meet the requirements of the product specification.

12.2 Other Tests—For other tests, a specimen shall be taken from two of the sample pieces selected in accordance with 11.1.2. The required tests shall be made on each of the specimens so selected.

12.3 Retests:

12.3.1 If any test specimen shows defective machining or develops flaws, it may be discarded and another specimen substituted.

12.3.2 If the percent elongation of any test specimen is less than that specified, and any part of the fracture is outside the middle two-thirds ofthe gage length, or in a punched or scribed mark within the reduced section, a retest shall be allowed.

12.3.3 If one of the tests made to determine any of the mechanical properties fails to meet a specified limit, this test shall be repeated on two of the remaining pieces selected in accordance with 11.1.2, and the results of both of these tests shall comply with the specified requirements.

12.3.4 If the chemical analysis fails to conform to the specified limits, analysis shall be made on a new composite sample prepared from the pieces selected in accordance with 11.1.2. The results ofthis retest shall comply with the specified requirements.

13. ASTM B171/B171M Tube Sheet Test Methods

13.1 The properties and chemical compositions enumerated in this specification shall, in case of disagreement, be determined in accordance with the following ASTM test methods:

13.1.1 Tension—E8/E8M.

13.1.2 ASTM B171/B171M Tube Sheet Chemical Analysis

13.2 In case ofdisagreement, the sulfur content ofthe alloys covered in this specification shall be determined in accordance with the method given in the annex to Specification B248 or B248M.

14. ASTM B171/B171M Tube Sheet Significance of Numerical Limits

14.1 For purposes of determining compliance with the specified limits for requirements of the properties listed in the following table and for dimensional tolerances, an observed or a calculated value shall be rounded as indicated in accordance with the rounding method of Practice E29: Property Rounded Unit for Observed or Calculated Value

Chemical composition nearest unit in the last right hand significant digit used in expressing the limiting value

Tensile strength nearest ksi [nearest 5 MPa]

Yield strength nearest ksi [nearest 5 MPa]

Elongation of 5 % and over nearest 1 %

15. ASTM B171/B171M Tube Sheet Inspection

15.1 The manufacturer shall inspect and perform the tests necessary to verify that the product furnished conforms to the requirements of this specification.

15.2 If, in addition, source inspection of the material by the purchaser is agreed upon by the manufacturer and the purchaser as part of the purchase contract, the nature of the facilities needed to satisfy the inspector representing the purchaser that the product is being furnished in accordance with this specification shall be included in the agreement. All tests and the inspection shall be conducted so as not to interfere unnecessarily with the operation of the works.

15.3 The manufacturer and the purchaser, by mutual agreement, may accomplish the final inspection simultaneously.

16. ASTM B171/B171M Tube Sheet Rejection and Rehearing

16.1 Rejection—Material that fails to conform to the requirements ofthis specification when inspected or tested by the purchaser or his agent may be rejected. Rejections shall be reported to the manufacturer or supplier promptly. In addition, a written notification or rejection shall follow.

16.2 Rehearing—In case of dissatisfaction with the results of the test, the manufacturer or supplier may make claim for rehearing.

17. ASTM B171/B171M Tube Sheet Certification

17.1 When specified on the purchase order or contract, the manufacturer shall furnish to the purchaser a certificate stating that each lot has been sampled, tested, and inspected in accordance with this specification and has met the requirements.

17.2 When material is specified to meet the requirements of ASME Boiler and Pressure Vessel Code, the certification requirements are mandatory.

18. ASTM B171/B171M Tube Sheet Test Report

18.1 When specified in the contract or purchase order, a report of test results shall be furnished.

19. ASTM B171/B171M Tube Sheet Packaging and Package Marking

19.1 Packaging:

19.1.1 The product shall be separated by size, composition, and temper, and prepared for shipment in such a manner as to ensure acceptance by common carrier for transportation and to afford protection from the normal hazards of transportation.

19.2 Package Marking:

19.2.1 Each shipping unit shall be legibly marked with the purchase order number, metal or alloy designation, temper, size, shape, gross and net weight, and name of supplier. The specification number shall be shown, when specified.

19.3 Product Identification:

19.3.1 For ASME Boiler and Pressure Vessel Code applications, the name or trademark of the manufacturer and the manufacturer’s lot identification number shall be legibly stamped or stenciled on each finished plate and sheet in two places not less than 12 in. [300 mm] from the edges. Ifthe plate and sheet are too small to locate the markings in this way, the markings may be placed near the center of the plate and sheet. In the case of butt straps, the markings may be placed 12 in. [300 mm] from the end. The plate number and type shall belegibly stamped on each plate and on each test specimen.

20. ASTM B171/B171M Tube Sheet Keywords

20.1 admiralty metal plate and sheet; aluminum bronze plate and sheet; aluminum-nickel bronze plate and sheet; copper nickel plate and sheet; muntz metal plate and sheet; naval brass plate and sheet; plate and sheet for pressure vessels; UNS No. C36500; UNS No. C43300; UNS No. C44400; UNS No. C44500; UNS No. C46400; UNS No. C46500; UNS No. C61300; UNS No. C61400; UNS No. C63000; UNS No. C63200; UNS No. C70600; UNS No. C70620; UNS No. C71500; UNS No. C71520.

Standard ASTM B171/B171M download Links

UploadFiles/File/2022122421270121.pdf