Lord Fin Tube-ASTM B444 UNS N06625 Tube

What is ASTM B444 Standard?

ASTM B444 Standard Nickel-Chromium-Molybdenum-Columbium Alloys (UNS N06625 and UNS N06852) and Nickel-Chromium-Molybdenum-Silicon Alloy (UNS N06219) Pipe and Tube

1.1 This specification 2 covers nickel-chromium-molybdenum-columbium alloys (UNS N06625 and UNSN06852) and nickel-chromium-molybdenum-silicon alloy(UNS N06219) 3 in the form of cold-worked seamless pipe and tube. The general requirements for pipe and tube are covered by Specification B829.

1.1.1 UNS N06625 products are furnished in two grades of different heat-treated conditions:

1.1.1.1 Grade 1 (annealed)—Material is normally employed in service temperatures up to 1100°F (593°C).

1.1.1.2 Grade 2 (solution annealed)—Material is normally employed in service temperatures above 1100°F (593°C) when resistance to creep and rupture is required.

N OTE 1—Hot-working or reannealing may change properties significantly, depending on working history and temperatures.

1.1.2 Alloys UNS N06219 and UNS N06852 are supplied in the solution annealed condition only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

2. ASTM B444 Referenced Documents

2.1 ASTM Standards:

B829 Specification for General Requirements for Nickel and Nickel Alloys Seamless Pipe and Tube

E112 Test Methods for Determining Average Grain Size

G28 Test Methods for Detecting Susceptibility to Inter-granular Corrosion in Wrought, Nickel-Rich, Chromium-Bearing Alloys

G48 Test Methods for Pitting and Crevice Corrosion Resis-tance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution

3. ASTM B444 General Requirement

3.1 Material furnished under this specification shall con-form to the applicable requirements of Specification B829 unless otherwise provided herein.

4. ASTM B444 Ordering Information

4.1 Orders for material to this specification shall include information with respect to the following:

4.1.1 Alloy name or UNS number,

4.1.2 ASTM designation,

4.1.3 Condition (temper) (see 1.1.1, 1.1.2, Section 6, and Appendix X1 and Appendix X2),

4.1.3.1 If neither grade of N06625 is specified, Grade 1 will be supplied.

4.1.4 Finish

4.1.5.1 Tube—Specify outside diameter and nominal or minimum wall,

4.1.5.2 Pipe—Specify standard pipe size and schedule,

4.1.5.3 Length—Cut to length or random,

4.1.6 Quantity—Feet (or metres) or number of pieces,

4.1.7 Hydrostatic Test or Nondestructive Electric Test—Specify type of test (see 6.2),

4.1.8 Hydrostatic Pressure Requirements—Specify test pressure if other than required by 9.1.1,

4.1.9 Certification—State if certification is required,

4.1.10 Samples for Product (Check) Analysis—State whether samples for product (check) analysis should be fur-nished (see 5.2),

4.1.11 Purchaser Inspection—If purchaser wishes to witness tests or inspection of material at place of manufacture, the purchase order must so state indicating which tests or inspections are to be witnessed

4.1.12 Small-Diameter and Light-Wall Tube (Converter Sizes)—See Appendix X1 and Table 1.

4.1.13 Supplementary Ordering Requirements: Grain Size Test (S1): Intergranular Corrosion Test (S2); Pitting and Crevice Corrosion Test (S3) may be ordered as an option by the purchaser in the purchase order indicating which tests are to be included.

5. ASTM B444 Chemical Composition

5.1 The material shall conform to the composition limits specified in Table 2. One test is required for each lot as defined in Specification B829.

5.2 If a product (check) analysis is performed by the purchaser, the material shall conform to the product (check) analysis variations in Table 2 of Specification B829.

6. ASTM B444 Mechanical Properties and Other Requirements

6.1 Tension Test—The material shall conform to the tensile properties specified in Table 1. The sampling and specimen preparation are as covered in Specification B829.

7. ASTM B444 Dimensions and Permissible Variations

7.1 Permissible variations for material specified as small diameter and light-wall tube (converter size) shall conform to the permissible variations prescribed in Table X1.1 and Table X1.2.

8. ASTM B444 Number of Tests

8.1 Chemical Analysis—One test per lot.

8.2 Tension—One test per lot.

8.3 Hydrostatic or Nondestructive Electric Test—Each piece in each lot.

9. ASTM B444 Test Methods

9.1 Hydrostatic Test—Each pipe or tube with an outside diameter 1 ⁄ 8in. (3 mm) and larger and with wall thickness of 0.015 in. (0.38 mm) and over shall be tested in accordance with Specification B829. The allowable fiber stress for material in the condition furnished, is as follows:

UNS N06625:

Grade 1—30 000 psi (207 MPa)

Grade 2—25 000 psi (172 MPa)

UNS N06219:

All—24 000 psi (165 MPa)

UNS N06852:

All—21 000 psi (145 MPa)

9.1.1 When so agreed upon by the manufacturer and purchaser, pipe or tube may be tested to 1 1 ⁄ 2 times the allowable fiber stress given above.

9.1.2 If any pipe or tube shows leak during hydrostatic testing, it shall be rejected.

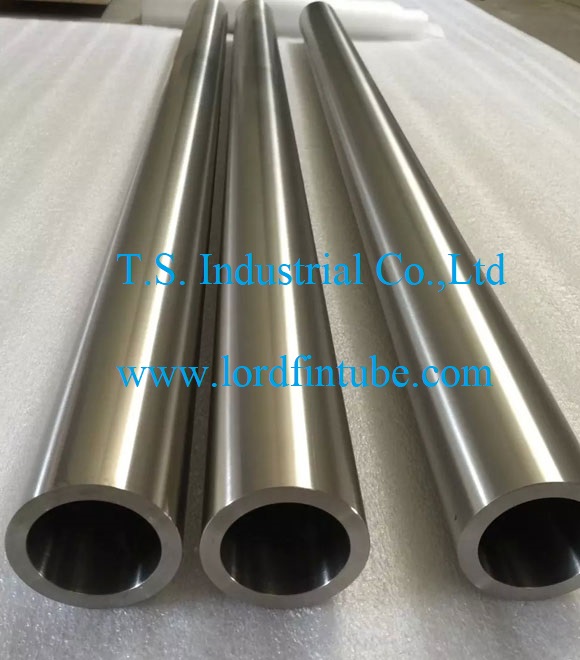

ASTM B444 UNS N06625 is a specification for nickel-chromium-molybdenum-columbium alloy (UNS N06625) seamless and welded tubes. This alloy is also commonly known as Inconel 625.

The ASTM B444 specification covers tubes in various sizes and wall thicknesses, with the option for either seamless or welded construction. These tubes are intended for general corrosion-resistant and heat-resistant applications, including high-temperature service.

The mechanical properties of ASTM B444 UNS N06625 tubes are typically excellent, with high tensile strength, good ductility, and good fatigue resistance. Additionally, these tubes have excellent corrosion resistance in a range of environments, including seawater and acidic environments.

Typical applications for ASTM B444 UNS N06625 tubes include chemical processing equipment, aerospace components, and marine applications. These tubes are also commonly used in oil and gas production, as well as in power generation and other high-temperature applications where corrosion resistance and strength are critical.

Its important to note that the ASTM B444 specification only covers the requirements for the tubes themselves, and not any associated fittings or components.