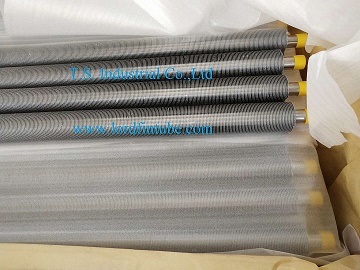

Lord Fin Tube-Extruded Duplex Steel Fin Tube

Extruded Duplex Steel Fin Tube: A Durable and Reliable Solution

When it comes to selecting the right material for a fin tube, durability and reliability are crucial factors to consider. Extruded Duplex Steel Fin Tube is a top choice for many industries due to its unique properties and exceptional performance.

Base Tube Material: SA789-S31803

SA789-S31803 is a type of Duplex Stainless Steel that is widely used in various applications due to its excellent corrosion resistance and high strength. It is a two-phase microstructure that consists of both austenitic and ferritic stainless steels, making it highly resistant to stress corrosion cracking, pitting, and crevice corrosion.

Extruded Duplex Steel Fin Tube

Extruded Duplex Steel Fin Tube is a type of heat exchanger tube that has fins extruded on its outer surface. The fins increase the surface area of the tube, which enhances heat transfer efficiency. The extrusion process creates a strong bond between the fins and the tube, making it highly durable and resistant to mechanical damage.

Extruded Duplex Steel Fin Tube Applications

Extruded Duplex Steel Fin Tube is widely used in various industries, including petrochemical, chemical, power generation, and offshore oil and gas. It is commonly used in heat exchangers, air coolers, condensers, and boilers due to its exceptional thermal conductivity and resistance to corrosion.

Heat Exchangers: Used in various types of heat exchangers, including air coolers, condensers, and economizers.

Chemical Processing: Suitable for use in chemical plants where resistance to aggressive chemicals is required.

Marine Applications: Ideal for marine environments due to its resistance to seawater corrosion.

Power Plants: Utilized in power generation facilities for cooling and heat recovery processes.

Extruded Duplex Steel Fin Tube Advantages

One of the main advantages of Extruded Duplex Steel Fin Tube is its exceptional resistance to corrosion. It can withstand harsh environments and corrosive media, making it ideal for use in offshore oil and gas applications. Additionally, its high strength and durability make it resistant to mechanical damage, ensuring a long service life.

Enhanced Heat Transfer Efficiency: The extrusion process ensures a seamless bond between the tube and the fins, maximizing thermal performance.

Corrosion Resistance: The duplex stainless steel provides superior resistance to various forms of corrosion, extending the life of the tubes.

Strength and Durability: The high mechanical strength of duplex stainless steel makes these tubes suitable for high-pressure and high-temperature applications.

Versatility: Suitable for a wide range of industries and applications, from chemical processing to power generation and marine environments.

Extruded Duplex Steel Fin Tube Typical size

|

Extruded Duplex Steel SA789-S31803 Fin Tube |

||||

|

Base Tube Material |

Fin Material |

Tube Length (mm) |

Fin length (mm) |

Fin Tube Quantity (Pc) |

|

SA789-S31803 |

SB209 1060 |

5490 |

5400 |

1248 |

|

Base Tube O.D (mm) |

Base Tube Thickness (mm) |

Fin Height (mm) |

Fin Thickness (mm) |

Fin Pitch |

|

25.4 |

1.65 |

15.88 |

0.4 |

394FPM |

|

ASTM A789 is a Standard Specification for Seamless and Welded Ferritic / Austenitic Stainless Steel Tubing for General Service. |

||||

Extruded Duplex Steel Fin Tube:

Extruded Duplex Steel Fin Tubes are a specialized type of heat exchanger tube designed to provide excellent thermal performance and corrosion resistance. These tubes are widely used in applications that require high strength, resistance to stress corrosion cracking, and superior thermal conductivity.