Copper Nickel 90/10 Elliptical Fin Tubes

In power generation and marine engineering, efficient heat transfer with exceptional corrosion resistance is critical. Copper Nickel 90/10 Elliptical Fin Tubes represent a specialized solution developed specifically for these challenging environments. As a manufacturer with decades of experience, we engineer these components to deliver reliable performance in seawater-cooled power station generators and other critical systems.

Key Manufacturing Insight

Unlike standard round tubes, the elliptical profile of the base tube creates a streamlined external geometry. This shape fundamentally alters the fluid dynamics around the tube bundle, reducing airside or waterside pressure drop by an average of 15-25% compared to equivalent round tube arrangements. This efficiency gain allows for more compact heat exchanger design without sacrificing thermal performance.

Copper Nickel 90/10 Elliptical Fin Tubes Performance Comparison

The selection of heat exchanger tubing involves balancing multiple factors. The table below provides a clear comparison between Copper Nickel 90/10 elliptical fin tubes and other common materials, based on data collected from field applications and manufacturer testing.

| Property / Material | Copper Nickel 90/10 Elliptical | Carbon Steel Round Finned | Stainless Steel 316 Round | Aluminum Elliptical |

|---|---|---|---|---|

| Seawater Corrosion Resistance | Excellent | Poor | Good (risk of crevice corrosion) | Fair (requires coating) |

| Thermal Conductivity (W/m·K) | 45 - 50 | 45 - 50 | 16 - 20 | 200 - 240 |

| Typical External Pressure Drop | Low (elliptical advantage) | High | High | Low |

| Biofouling Tendency in Seawater | Low (CuNi surface inhibits growth) | High | Medium | High |

| Material Cost Index | High | Low | Medium-High | Medium |

| Optimal Application | Seawater coolers, offshore platforms, power stations | Air heaters, economizers (non-corrosive gas) | Chemical processes, freshwater cooling | Air conditioning, low-temp gas cooling |

Copper Nickel 90/10 Elliptical Fin Tubes Design Advantages

The combination of the 90/10 copper-nickel alloy with an elliptical finned design creates unique benefits that are not achievable with traditional round tubes. These advantages are why engineers specify them for critical cooling duties.

- Compact Heat Exchanger Layout: The elliptical footprint allows tubes to be arranged with tighter transverse and longitudinal pitch. This increases the heat transfer surface area per unit volume of the exchanger shell, reducing the overall equipment footprint—a crucial factor in space-constrained installations like offshore platforms or ship engine rooms.

- Reduced Fluid Resistance: The aerodynamic/ hydrodynamic shape of the elliptical tube presents a lower drag coefficient to cross-flowing fluids (air or water). This translates directly to lower pumping or fan power consumption, reducing the operational cost of the heat exchanger system over its 20+ year lifespan.

- Enhanced Heat Transfer Periphery: For two tubes with the same cross-sectional flow area, the elliptical tube has a longer external perimeter. This provides more primary surface for fin attachment and direct heat transfer, boosting efficiency before the fin contribution is even calculated.

- Robust Mechanical Design: The rectangular or square fins (typically carbon steel, stainless, or CuNi) are wound under high tension and often welded or embedded. This creates a rigid, durable structure resistant to fin vibration and frost damage in exposed, low-temperature environments.

- Manufacturing Flexibility: The fin spacing (fins per inch) and height can be precisely varied along the tube length or between tube rows to optimize thermal and pressure drop performance for specific duty points, a service we frequently provide as a manufacturer.

Copper Nickel 90/10 Elliptical Fin Tubes Manufacturing Process

Producing a reliable elliptical finned tube requires precision and control at each stage. Our manufacturing protocol ensures every tube meets the stringent requirements for marine and power applications.

Material Selection and Tube Formation

We start with seamless CuNi 90/10 (UNS C70600) base tubes, certified to ASTM B466 or equivalent standards. The elliptical shape is formed via a cold-drawing process that ensures uniform wall thickness and precise major/minor axis dimensions. This is more complex than round tube production but is essential for consistent performance.

Fin Application and Bonding

The fins—commonly carbon steel for mechanical strength or aluminum for maximum heat transfer—are spirally wound onto the elliptical tube using proprietary tensioning equipment. The key is achieving a consistent, tight mechanical bond (ML-fin) or proceeding with a brazing or welding process (G-fin, L-fin) to ensure zero contact resistance, which is critical for heat transfer efficiency.

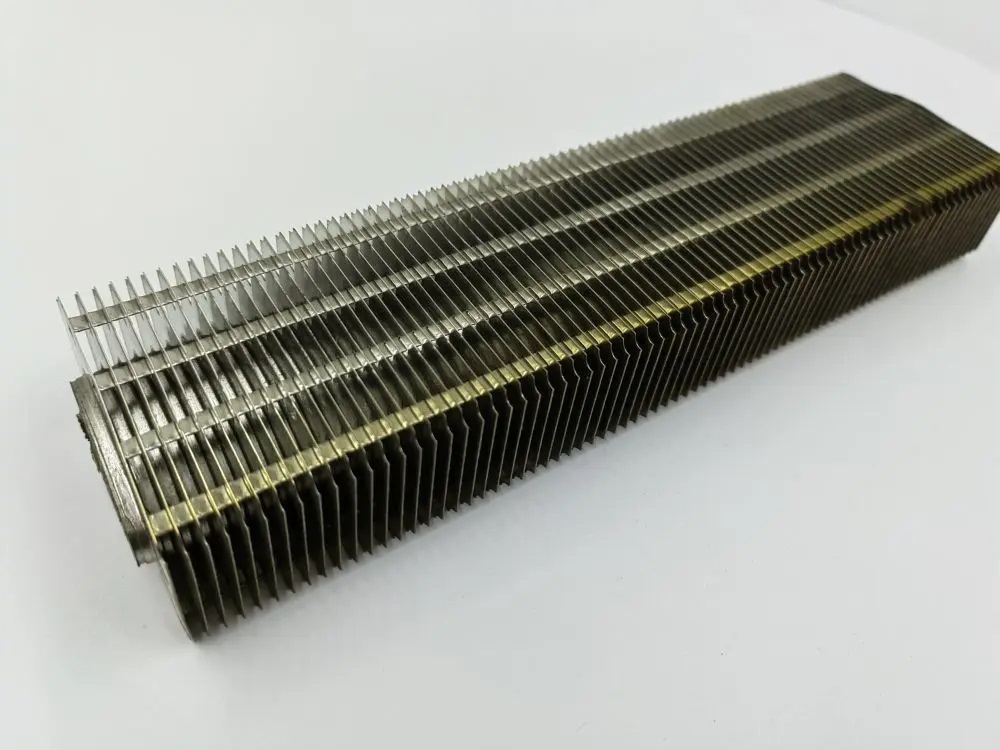

Elliptical Fin Tubes during final inspection, highlighting the tight spiral wrap and uniform fin spacing.

Quality Assurance and Testing

Every batch undergoes dimensional checks, pressure testing, and sample destructive testing. We perform pull tests to verify fin bond strength and often conduct thermal performance tests in our pilot-scale wind tunnel to validate heat transfer and pressure drop coefficients against design specifications.

Copper Nickel 90/10 Elliptical Fin Tubes Applications

The specific properties of these tubes make them the preferred choice in several high-value industrial sectors. Their longevity in harsh conditions often results in a lower total cost of ownership despite a higher initial investment.

Seawater-Cooled Power Station Condensers

Used as generator coolers and auxiliary system coolers where seawater is the primary coolant. The CuNi alloy resists chloride-induced pitting and stress corrosion cracking common in brackish water.

Offshore Oil & Gas Platform Cooling

Critical for cooling hydraulic power units, compressor intercoolers, and closed-loop cooling water systems on platforms, where space is premium and reliability is non-negotiable.

Marine Engine Jacket Water Coolers

In ship propulsion systems, these tubes handle the transition between high-temperature freshwater engine loops and raw seawater cooling, withstanding thermal cycling and microbial corrosion.

Desalination Plant Heat Rejection Sections

In multi-stage flash (MSF) or thermal vapor compression (TVC) plants, they manage heat rejection in sections with aggressive saline atmospheres and high-temperature brine.

Manufacturers Technical Advisory

When designing a bundle with Copper Nickel 90/10 Elliptical Fin Tubes, consider the rear row effect. The compact arrangement increases thermal interaction between rows. A common practice is to increase the fin spacing in the second and subsequent rows to manage overall pressure drop. We recommend a maximum of 4-6 tube rows for optimal balance between compactness and efficiency. Contact our engineering team for specific bundle layout assistance or to request a performance calculation for your duty conditions.

Copper Nickel 90/10 Elliptical Fin Tubes Specifications

Standard manufacturing ranges are listed below. Custom dimensions, fin materials (including cupronickel fins for all-CuNi construction), and special coatings for anti-fouling are available upon request.

| Parameter | Standard Range | Common Specification |

|---|---|---|

| Base Tube Material | CuNi 90/10 (UNS C70600) | ASTM B466, ASME SB466 |

| Elliptical Tube Dimensions (Major x Minor Axis) | 30mm x 15mm to 80mm x 40mm | Custom sizes available |

| Tube Wall Thickness | 1.2mm to 3.0mm | 1.5mm typical for seawater |

| Fin Material | Carbon Steel, Stainless Steel, Aluminum, CuNi | Selected based on service environment |

| Fin Height | 8mm to 20mm | 12.7mm (0.5") common |

| Fins Per Inch (FPI) | 3 to 7 | 5 FPI balanced for gas/air, 3 for liquid |

| Standard Length | Up to 12 meters | Cut to bundle drawing requirements |

The longevity and performance of Elliptical Finned Tubes in corrosive service depend as much on precise manufacturing as on material selection. As a dedicated manufacturer, we control the entire process from alloy verification to final inspection, ensuring that the tubes we ship meet the exacting standards required for power station generator coolers and other critical heat transfer applications. For engineers dealing with seawater, brackish water, or other challenging coolants, the elliptical design paired with CuNi 90/10 offers a proven, reliable solution that optimizes both space and energy consumption over the long term.