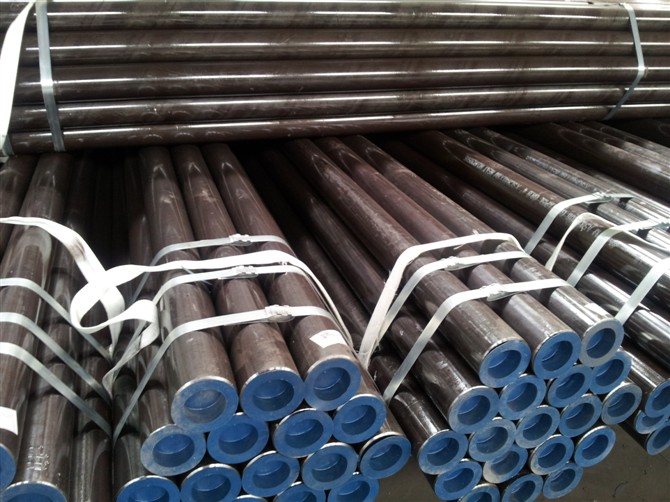

Lord Fin Tube-EN 10216-2 16Mo3 Seamless Steel Boiler Tubes

EN 10216-2 16Mo3 Seamless Steel Boiler Tubes, Boiler tubes for temperatures determined by grades, without determination of pressure level.

EN 10216-2 16Mo3 Tube Application:

- Boiler tubes designed for temperatures determined by grades, without a specific determination of pressure level.

16Mo3 Tube Standards:

- Complies with BS EN 10216, which outlines technical delivery conditions for seamless steel tubes for pressure purposes. This includes both non-alloy and alloy steel tubes with specified elevated temperature properties.

EN 10216-2 16Mo3 Tube Steel Grades:

- EN 10216-2 16Mo3 Seamless Steel Boiler Tubes are made from steel grades 16Mo3/15Mo3.

EN 10216-2 16Mo3 Tube Sizes Range:

- Outer Diameter (OD): 10.2mm-720mm

- Wall Thickness (WT): 1.6mm-100mm

EN 10216-2 16Mo3 Tube Chemical Composition (15Mo3):

- C: 0.12/0.20

- Ni: 0.30

- Si: 0.35

- Mn: 0.40/0.90

- P: 0.025

- S: 0.010

- Cr: 0.030

- N: 0.012

- Mo: 0.25/0.35

- Cu: 0.30

EN 10216-2 16Mo3 Tube Mechanical Properties (15Mo3):

- Yield Strength (R2):

- Wall Thickness <16mm: 280 MPa (minimum)

- Wall Thickness 16mm-40mm: 270 MPa (minimum)

- Wall Thickness 40mm-60mm: 260 MPa (minimum)

- Tensile Strength (Rm): 450-600 MPa

- Elongation (%)(L): 22 (minimum)

- Elongation (%)(T): 20 (minimum)

- Lzod Impact(J) at 20℃(L): 40 (minimum)

- Lzod Impact(J) at 20℃(T): 27 (minimum)

EN 10216-2 16Mo3 Tube Equivalent Standards:

- UNS: K 11562/Grade P12 / T12

- UNS: K 11597/Grade P11 / T11

- AFNOR: 16 Mo3 / EN 10216 (008/2007) (FR)

- BS: 16 Mo3 / EN 10216 (008/2007) (GB)

- ASTM A209/ASME SA 209 T1/ASTM A/ASMESA 209 T1A/ASTM A/ASMESA 209 T1B

EN 10216-2 16Mo3 Tube Additional Information:

- EN Symbol (short): 16Mo3 (alternative: 15Mo3)

The seamless steel boiler tubes in accordance with EN 10216-2 16Mo3 standards are well-suited for high-temperature applications and demonstrate specific mechanical and chemical properties to ensure reliable performance in boiler systems.