Why Fin Tube Using Temperature is Important?

Fin Tube Use Temperature

Finned tubes are essential components in heat exchangers, designed to improve heat transfer efficiency across a variety of industrial applications. One crucial factor in selecting the appropriate finned tube is understanding its temperature range capabilities.

Why Is Fin Tube Use Temperature Important?

The operating temperature of a finned tube determines its efficiency, durability, and safety in various applications. High temperatures can impact the bonding between the fin and the base tube, leading to decreased performance or potential failure. Hence, selecting a fin tube that matches your application’s temperature range is critical for optimal performance.

Types of Finned Tubes and Their Temperature Ranges

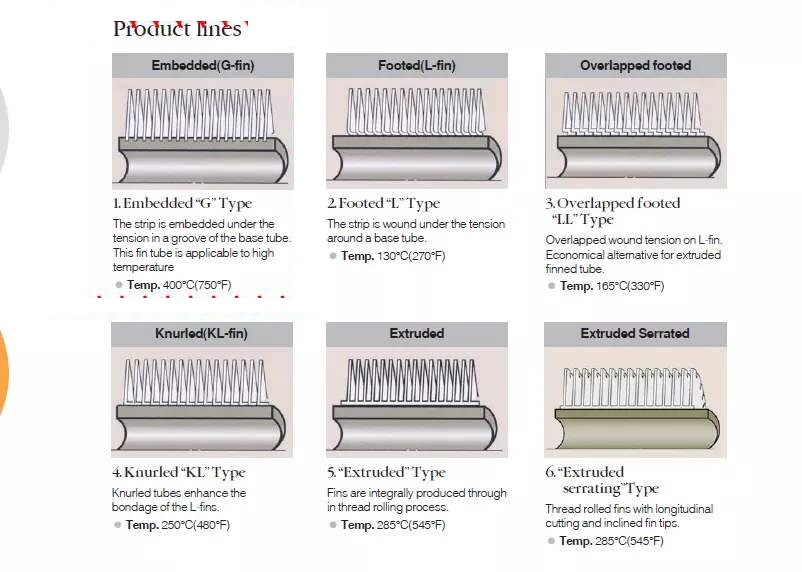

⇒Embedded "G" Type Finned Tubes

Description: The fin strip is embedded under tension in a groove on the base tube.

Temperature Range: Up to 400°C (750°F).

Applications: Suitable for high-temperature applications like boilers, power plants, and industrial heat exchangers.

⇒Footed "L" Type Finned Tubes

Description: The fin strip is wound under tension around the base tube.

Temperature Range: Up to 130°C (270°F).

Applications: Ideal for low-temperature heat transfer systems, such as HVAC units and small-scale heat recovery systems.

⇒Overlapped Footed "LL" Type Finned Tubes

Description: The fins are overlapped and wound tightly, providing increased durability and resistance.

Temperature Range: Up to 165°C (330°F).

Applications: A cost-effective option for moderate-temperature systems in chemical processing and industrial dryers.

⇒Knurled "KL" Type Finned Tubes

Description: Knurling enhances the bonding between the fin and the base tube, ensuring better stability.

Temperature Range: Up to 250°C (480°F).

Applications: Commonly used in medium-temperature systems, including heat recovery units and economizers.

⇒Extruded Finned Tubes

Description: Fins are integrally formed through a thread rolling process, providing seamless construction.

Temperature Range: Up to 285°C (545°F).

Applications: Frequently used in high-efficiency heat exchangers for industrial and chemical processes.

⇒Extruded Serrated Finned Tubes

Description: These tubes feature thread-rolled fins with longitudinal cuts and inclined tips for improved heat transfer.

Temperature Range: Up to 285°C (545°F).

Applications: Perfect for systems requiring enhanced heat transfer performance, such as gas turbines and thermal oil heaters.

Choosing the Right Finned Tube

The application type should align with the tube’s characteristics, such as durability and cost-efficiency, to meet specific system requirements. Material compatibility is also essential, particularly in corrosive or high-humidity environments where corrosion-resistant materials enhance longevity. Understanding the temperature capabilities of different finned tubes helps maximize heat exchanger efficiency and lifespan—high-temperature "G" type tubes are ideal for industrial boilers, while cost-effective "L" type tubes work well for HVAC systems, ensuring optimal heat transfer and reduced maintenance costs.