Lordfintube-Finned Tube Air-Cooled Heat Exchanger

An air cooled heat exchanger is typically composed of major components such as tube bundles, headers, fans, louvers, and a structural frame. It is the most widely used type of heat exchange equipment for condensation and cooling applications in petroleum, chemical, and gas processing industries.

The air cooler is a key piece of equipment for energy conservation and consumption reduction in modern industry. The core of its performance lies in the efficient and reliable finned tubes. In numerous industrial sectors such as petroleum & chemicals, power generation, and metallurgy, the substantial waste heat generated during production processes is often efficiently, economically, and environmentally removed using air coolers.

Application of Air Coolers in the Power Industry

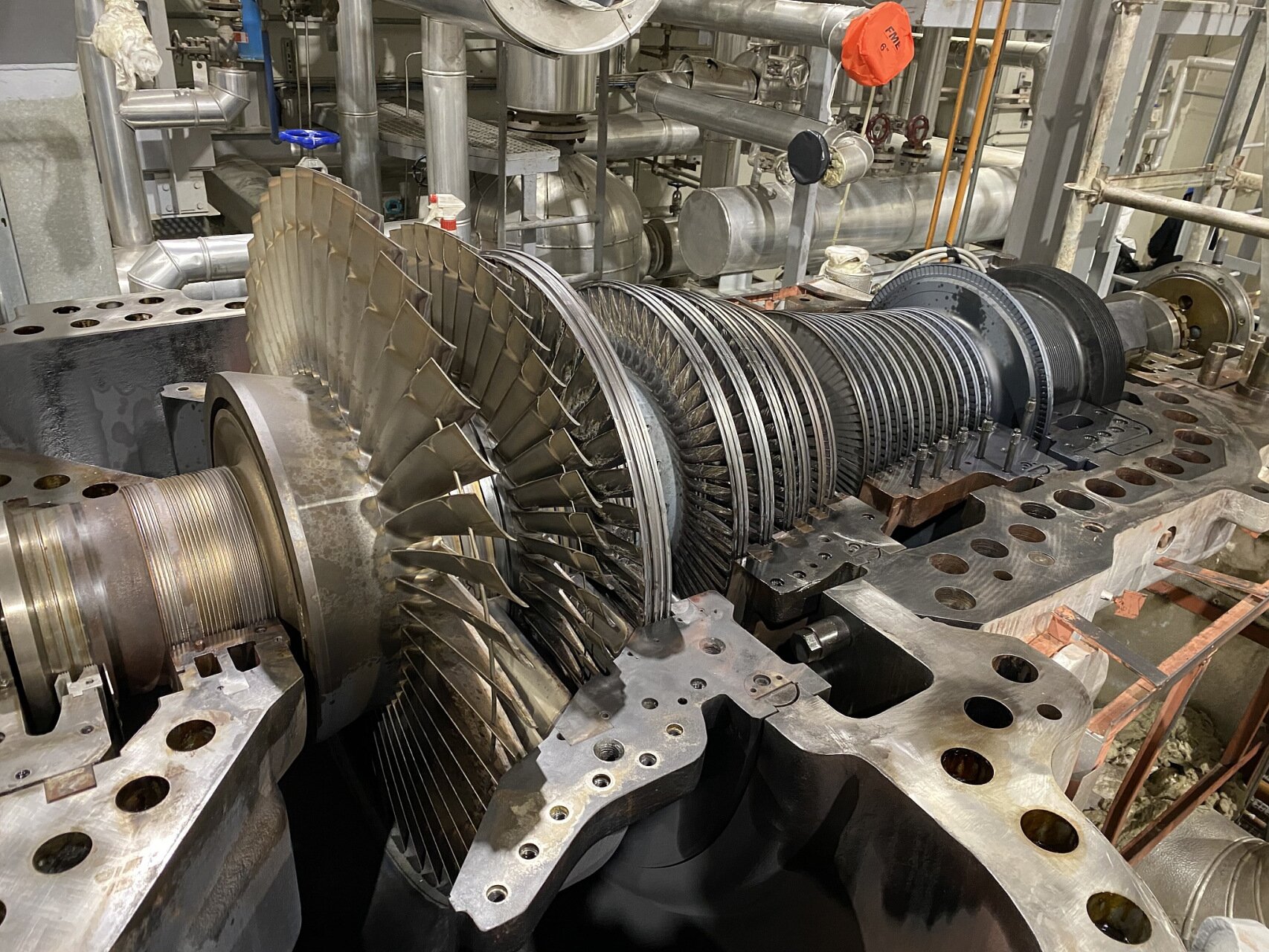

In power plants (especially thermal and nuclear), the core function of an air cooler is to condense the exhaust steam from turbines to create a vacuum, which is a crucial link for improving the efficiency of the thermal cycle.

The traditional method uses circulating water for cooling in condensers, whereas air coolers use air instead.

This is a direct air-cooling method. A large air-cooled condenser (composed of dozens or even hundreds of finned tube modules) directly condenses the high-temperature exhaust steam from the low-pressure cylinder into water (condensate), thereby establishing and maintaining a high vacuum at the turbine exhaust. The higher the vacuum, the greater the available enthalpy drop of the steam, and thus the higher the power generation efficiency.

This is an indirect air-cooling method. In a hybrid (or mixing) condenser, exhaust steam is condensed by direct contact with sprayed cooling water. The heated cooling water is then pumped to an air cooler where it is cooled by air before being recirculated back to the condenser. The system is completely closed, with no evaporative losses.

In power plants, air coolers are also used for cooling auxiliary boiler systems, such as turbine/generator bearing lubricating oil, hydrogen in hydrogen-cooled generators, boiler feed pump motors, etc. It is essential to ensure these critical auxiliary operate at optimal temperatures to prevent equipment damage, efficiency loss, or fire risks due to overheating.

Application of Air Coolers in the Petrochemical Industry

- Condensation of overhead vapors and product cooling in refinery units such as Atmospheric and Vacuum Distillation Towers, Catalytic Cracking, Hydrotreating, etc.

- Condensation of cracked gases like ethylene and propylene.

From the above applications, the importance of air coolers in modern industry is evident. Now, lets understand what an air cooler is.

What is an Air Cooler?

An efficient heat exchanger that uses ambient air to cool or condense high-temperature process fluids inside tubes.

Working Principle: The process fluid requiring cooling flows inside the finned tubes, while ambient air driven by fans flows transversely or is forced over the external surface of the finned tube bundle. Through the finned tubes, an efficient heat transfer element, heat from the fluid inside the tubes is transferred to the air outside, thereby achieving cooling.

Cooling Medium

Air

Cooled Medium

Process fluids, circulating water, turbine exhaust steam.

Main Structure

- Core Heat Transfer Element: Finned Tubes

- Other Components: Fans, Structural Frame, Louvers, Plenum (Air Box), and other parts forming the tube bundle.

Finned Tubes for Air Cooled Heat Exchanger

As a professional finned tube manufacturer, we understand that finned tubes are the core determinant of an air coolers efficiency and service life. Their primary function is to extend the external heat transfer area, significantly enhancing heat transfer.

Based on manufacturing processes and performance characteristics, they are mainly classified as follows:

A metal strip (typically aluminum) is tension-wound around the base tube (carbon steel, stainless steel) surface, with the foot forming an "L" shape.

Advantages: Most cost-effective, longest application history.

Disadvantages: Relatively high contact thermal resistance, moderate heat transfer efficiency. Risk of loosening under vibration or thermal cycling.

Also employs a wound fin method, but the fin strip foot has a special "LL" shaped structure for a tighter mechanical interlock.

Characteristics: Compared to L-type, provides greater contact area and stronger mechanical bond, reducing contact thermal resistance and offering better resistance to loosening and vibration.

During the winding process, the "L" shaped foot of the fin is simultaneously knurled/rolled, creating a tight interlock with a pre-treated base tube surface.

An aluminum sleeve is fitted over the outer wall of a liner tube. Then, it is synchronously rolled to form fins from the aluminum layer while achieving a metallurgically tight bond with the liner tube.

Spiral grooves are pre-rolled onto the base tube surface. The foot of the fin strip is embedded into these grooves and rolled tight, forming a mechanical interlock.

Consists of a base tube with a flat cross-section and continuous serpentine aluminum fins brazed onto its two external sides.

Design Features: The flat base tube increases contact area. The serpentine fins disturb airflow, enhancing heat transfer.

Types of Air Coolers

1. Classification by Ventilation Method

This classification is based on the relative position of the fan to the tube bundle, determining airflow organization and operational/maintenance characteristics.

| Type | Forced-Draught Air-Cooled Exchanger | Induced-Draught Air-Cooled Exchanger |

|---|---|---|

| Fan Position | Fan located below the tube bundle, blowing air onto it. | Fan located above the tube bundle, drawing air through it. |

| Advantages | Fan operates in cool air, favorable motor conditions, easier maintenance; Tube bundle upstream, less fin fouling. | Uniform air distribution; Smooth hot air exhaust, minimal hot air recirculation (~70% lower), slightly higher efficiency; Tube bundle protected from rain/snow. |

| Disadvantages | Slightly uneven air distribution; More susceptible to weather (rain/snow). | Fan operates in hot exhaust stream, harsh environment for motor and drive components, higher maintenance requirements. |

| Application | Suitable for clean air, dry climates. Most common form in petrochemical industry. | Suitable for high-temperature, windy, space-constrained sites, or where strict control of hot air recirculation is required, e.g., large power plant direct air-cooled systems. |

2. Classification by Tube Bundle Layout

This classification is based on the installation angle of the tube bundle, directly affecting footprint, heat transfer efficiency, and freeze protection.

Structural Feature: Tube bundle placed horizontally, airflow passes vertically.

Advantages: Simple structure, easiest maintenance (e.g., cleaning); Lower cost.

Disadvantages: Largest footprint; Requires special attention to condensate drainage and freeze protection in winter.

Application: Suitable for cooling/condensing most media. Most widely used.

Structural Feature: Tube bundle placed in an inclined "A" shape.

Advantages: Smaller footprint (~40% of horizontal type); Excellent gravity-driven condensate drainage, beneficial for winter freeze protection; Combines advantages of horizontal and vertical types.

Application: Particularly suitable for condensing turbine exhaust steam.

3. Classification by Cooling Process

This classification is based on whether evaporative cooling is introduced to enhance heat transfer, determining cooling capacity and environmental adaptability.

| Type | Dry Air Cooler | Wet (Evaporative) Air Cooler | Dry-Wet Combined Air Cooler |

|---|---|---|---|

| Principle | Uses only sensible heat of air for cooling. | Enhances cooling by spraying water on fins, utilizing evaporative heat absorption. | Dry section handles base load. Wet section activates during hot seasons for peak cooling. |

| Advantages | 100% water saving, simple O&M, no water pollution. | High cooling capacity. Outlet temp can approach ambient wet-bulb temp, much lower than dry type. | Combines advantages of both. Ensures water savings most of the time while handling extreme heat for process stability. |

| Disadvantages | Cooling capacity limited by ambient dry-bulb temp; efficiency drops in summer heat. | Water consumption. Risk of scaling, corrosion. Requires water treatment system. | Complex system, higher investment, demanding control requirements. |

| Application | Suitable for water-scarce regions, areas with consistently moderate temps, or where final cooled temp requirement is not strict. | Suitable for low humidity environments, applications requiring large cooling ΔT, and where water is relatively available. | Suitable for critical processes with strict cooling temp requirements and significant seasonal temperature fluctuations. An optimal balance for energy/water savings. |

Dry-wet combined air coolers integrate the zero water consumption of dry air coolers with the high efficiency of wet cooling towers.

The upper section is a finned air cooler where the high-temperature circulating medium is pre-cooled in the dry system. If the water temperature drop is insufficient for process requirements, it proceeds to the second-stage wet system, entering smooth-tube heat exchanger coils. Spray water is cascaded from above, absorbing latent heat of vaporization through evaporation, consuming spray water, and further lowering the temperature of the circulating medium inside the coils.

Header Types for Air Coolers

The headers of an air cooler are responsible for distributing and collecting the process medium. Their structural form directly determines the equipments pressure capability, reliability, maintainability, and manufacturing cost.

1. Plug Header

Each finned tube end has a threaded plug (screw plug), facilitating tube expansion during assembly and tube bundle cleaning during maintenance. Due to simple manufacturing, this is the basic type widely used for medium and low-pressure tube bundles.

Allowable Working Pressure: ≤20 MPa

2. Cover Plate Header

The header end is sealed by a large cover plate flange using bolts and gaskets.

Characteristics: Excellent maintainability; Facilitates welding operations, ensuring high-quality tube-to-header welds.

Allowable Working Pressure: ≤6.4 MPa

3. Manifold (Pipe) Header

Uses large-diameter pipe headers instead of a rectangular box. Heat exchanger tubes (or U-tubes) are directly welded onto the headers.

Advantages: High pressure capability, relatively compact structure, saves steel.

Allowable Working Pressure: ≤35 MPa

4. Half-Round Pipe Header

The header is fully welded with no removable parts like plugs or cover plates, making it suitable for tube bundles requiring very high leak-tightness. However, as a welded thin steel plate component, it cannot withstand excessive pressure.

This type is typically used for tube bundles under vacuum, such as in turbine exhaust air-cooled condenser bundles.

Allowable Working Pressure: ≤6.4 MPa

Perhaps you are interested in Power Plant Air Cooling Systems?

In the field of power plant air-cooling technology, Direct Air Cooling (DAC) and Indirect Air Cooling (IAC) are two core technological approaches. Both belong to the category of "Power Plant Air Cooling Systems" or "Water-Saving Thermal Power Generation Technology." Their core purpose is to use air to replace large volumes of cooling water in water-scarce regions for condensing turbine exhaust steam.

| Type | Air Cooled Condenser (ACC) | Indirect Air Cooling System (IACS) |

|---|---|---|

| Core Principle | Turbine exhaust steam goes directly into the Air-Cooled Condenser (ACC) to be cooled by air. | Turbine exhaust steam first exchanges heat with cooling water in a condenser. The heated cooling water is then cooled by air in an air-cooling tower. |

| System Components | Turbine Exhaust Duct → Steam Distribution Pipes → Air-Cooled Condenser (ACC) → Fans | Turbine Exhaust → Hybrid (Mixing) Condenser → Circulating Water Pumps → Air Cooling Tower (with internal heat exchangers/radiators) → Return Water |

| Operating Features | High and fluctuating backpressure, sensitive to ambient wind speed/temperature, high fan power consumption. | Lower and more stable backpressure, operation closer to water-cooled systems, lower fan power consumption, but requires circulating water pump power. |

| Freeze Protection | More difficult to control. Requires significant hot air recirculation or precise fan control in winter. | Better. Can be controlled by adjusting circulating water flow and louvers. |

| Suitable Unit Size | Commonly used for units up to 600MW, flexible layout. | More suitable for large units (300MW, 600MW, even 1000MW). |

| Representative Tech | ACC (Air Cooled Condenser) | IDCS (Indirect Dry Cooling System), subdivided into Hamon type (surface condenser) and Heller type (hybrid/mixing condenser). |