Lord Fin Tube-ASTM A210 A1 G Type Fin Tube

What is ASTM A210 A1 G Type fin tube?

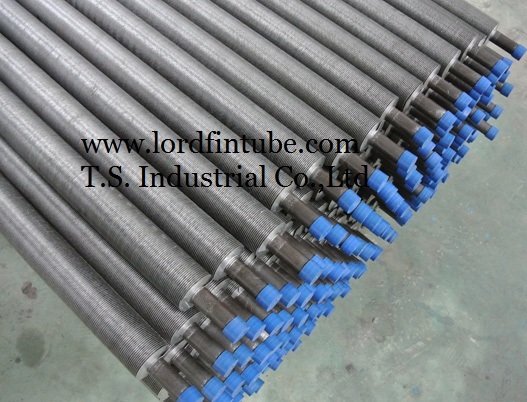

ASTM A210 A1 G Type Fin Tube refer to base tube inASTM A210 A1 and embedded aluminum strip as G type fins. The base tube is ASTM A210 A1 boiler tube and outside embedded G type fins. SA210 A1 is a seamless medium carbon steel boiler tube ideal for use in a variety of high-demand applications, including super heaters, heat exchangers, condensers, and marine environments. Its also suitable for refineries, paper pulping, petrochemicals, pressure vessels, and general engineering tasks. Additionally, this material finds application in coal, thermal, and oil power generation plants. SA210 A1 steel can be obtained in two finishes: hot finished (HF) and cold drawn (CD), and is produced using a killed steel process to enhance its properties.

1. ASTM A210 A1 G Type fin tube Definition:

- ASTM A210 A1: ASTM A210 A1 is a standard specification for seamless medium-carbon steel boiler and superheater tubes. It specifies the requirements for tubes used in high-temperature applications, such as boilers and superheaters.

- G Type Fin Tube: G Type Fin Tubes are characterized by the presence of integral fins on the outside surface of the tube. These fins are typically helical or spiral in shape, providing increased surface area for enhanced heat transfer.

2. Advantages of ASTM A210 A1 G Type fin tube:

- Improved heat transfer: The integral G type fins on the tube greatly increase the surface area available for heat exchange. This results in improved heat transfer efficiency, allowing for more effective heating or cooling processes.

- Compact design: The enhanced surface area achieved through G type fins allows for more compact heat exchanger designs. This is particularly beneficial when space is limited, as it allows for the efficient utilization of available area.

- Resistance to fouling: The design of G type fins helps minimize the accumulation of dirt, debris, or fouling agents on the finned surface. This reduces the risk of reduced heat transfer efficiency over time and can result in longer intervals between maintenance or cleaning procedures.

- Enhanced strength: The presence of integral fins on the tube enhances its structural integrity and mechanical strength. This makes the ASTM A210 A1 G Type Fin Tube more robust and capable of withstanding higher pressures and external forces.

- Cost-effective: G Type Fin Tubes offer a cost-effective solution for heat transfer applications. By maximizing heat transfer efficiency and utilizing less material compared to other methods, they provide an economical choice for various industries.

3. Application of ASTM A210 A1 G Type fin tube:

ASTM A210 A1 G Type Fin Tubes find application in a range of industries and processes, including:

- Power generation: They are commonly used in power plants for boilers, superheaters, and economizers, where the efficient transfer of heat is critical for power generation.

- Petrochemical industry: G Type Fin Tubes are utilized in heat exchangers, condensers, and process heaters within refineries and petrochemical plants, facilitating efficient heat exchange in various processes.

- HVAC systems: They are employed in air conditioning and refrigeration systems, allowing for effective heat transfer between the refrigerant and the surrounding air.

- Waste heat recovery: G Type Fin Tubes are used in thermal energy recovery systems to capture and utilize waste heat from industrial processes, improving overall energy efficiency.