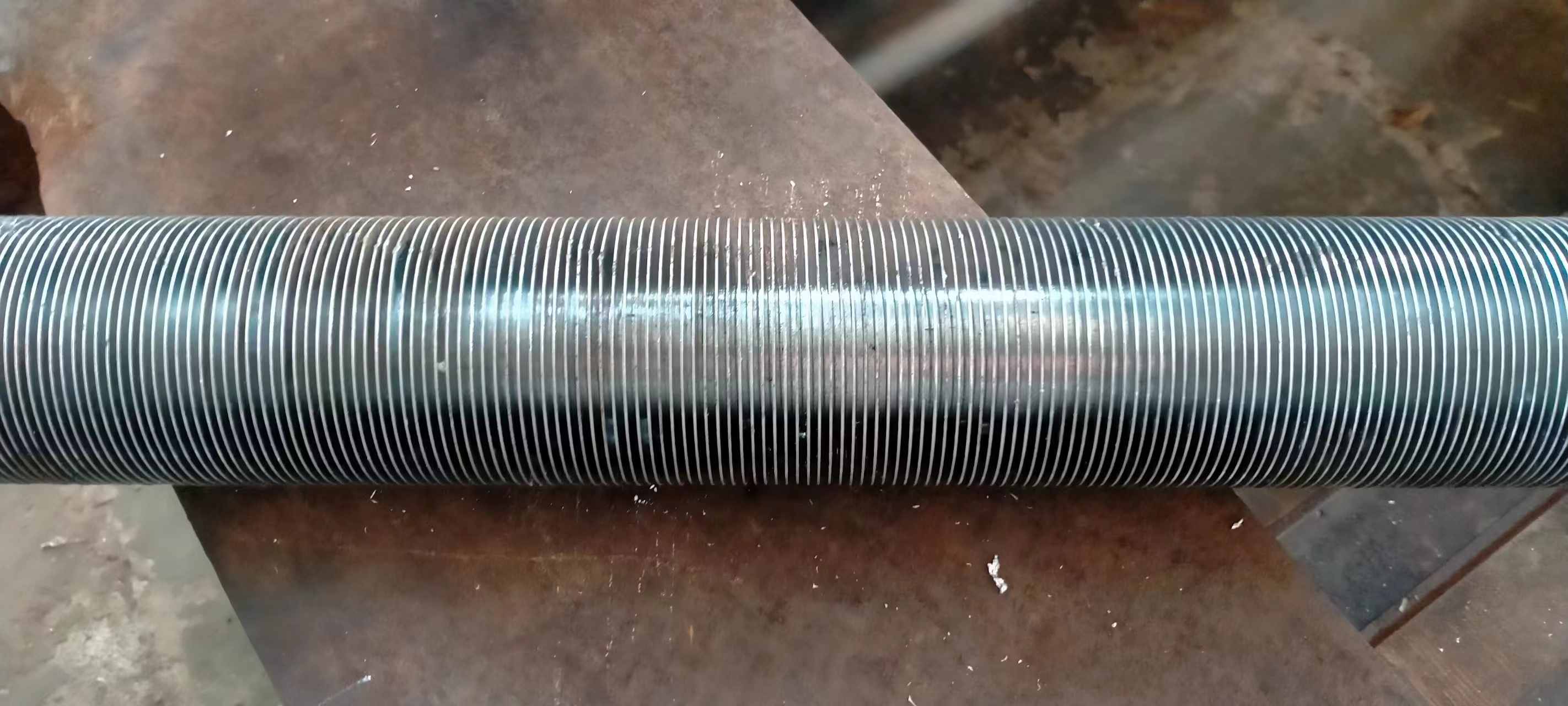

Galvanized Fin Tubes

Galvanized fin tubes represent a significant advancement in heat exchange technology, combining zinc-coated steel tubes with precision-engineered aluminum or copper fins. This comprehensive analysis examines their design principles, performance characteristics, and industrial applications, supported by empirical data and comparative studies.

Industry Insights

Market analysis indicates a 23% annual growth in galvanized fin tube adoption across industrial sectors, driven by increasing demand for corrosion-resistant heat exchange solutions in harsh operating environments.

Galvanized Fin Tubes Technical Superiority

The manufacturing process involves hot-dip galvanizing where steel tubes are immersed in molten zinc at 450°C, creating a metallurgical bond that provides exceptional corrosion protection. The fin attachment process increases heat transfer surface area by 35-45% compared to bare tubes.

Traditional Bare Tubes

- Limited corrosion resistance

- Lower heat transfer efficiency

- Frequent maintenance requirements

- Shorter service life (3-5 years)

- Higher lifecycle costs

Galvanized Fin Tubes

- Superior corrosion protection

- Enhanced thermal performance

- Reduced maintenance frequency

- Extended service life (12-15+ years)

- Lower total cost of ownership

Performance Metrics Comparison

| Performance Parameter | Bare Steel Tubes | Stainless Steel Tubes | Galvanized Fin Tubes |

|---|---|---|---|

| Corrosion Resistance Rating | Poor (C3-C4 environment) | Excellent | Very Good (C4-C5 environment) |

| Heat Transfer Coefficient (W/m²K) | 85-110 | 90-115 | 125-155 |

| Service Life (Years) | 3-5 | 8-12 | 12-18 |

| Maintenance Interval | 6-12 months | 18-24 months | 36-48 months |

| Initial Cost per Meter ($) | 15-25 | 45-65 | 28-42 |

| 10-Year Total Cost ($/meter) | 85-120 | 65-85 | 45-60 |

Galvanized Fin Tubes Industrial Applications

Chemical Processing Plant - Gulf Coast Facility

Challenge: Frequent tube failures due to chloride-induced corrosion in cooling systems, causing unplanned shutdowns costing $85,000 per incident.

Solution: Installation of Galvanized Fin Tubes with enhanced zinc coating (100-120 microns).

Results:

68% Reduction in Downtime 32% Improvement in Heat Transfer ROI: 14 Months

Coastal Hotel HVAC System - Miami Beach

Challenge: Rapid corrosion of copper tubes in salt-laden atmosphere, requiring replacement every 4-5 years.

Solution: Retrofit with galvanized fin tube heat exchangers in main HVAC units.

Results:

12+ Year Service Life $142,000 Lifecycle Savings Zero Maintenance Issues

Material Specifications & Standards

Base Tube Material: Carbon Steel ASTM A179 / A214

Zinc Coating: 80-120 microns (ASTM A123 compliance)

Fin Material: Aluminum 1100 / Copper C12200

Fin Types: Spiral wound, extruded, embedded

Quality Standards: ISO 9001:2015, ASME BPVC, ASTM A123

Galvanized Fin Tubes Manufacturing

The production of high-performance Galvanized Fin Tubes follows rigorous quality protocols:

- Material Selection: Premium carbon steel tubes with controlled chemical composition

- Surface Preparation: Acid cleaning and flux application for optimal zinc adhesion

- Hot-Dip Galvanizing: Immersion in molten zinc at 445-465°C for uniform coating

- Fin Attachment: Mechanical bonding or welding with precise fin spacing

- Quality Verification: Coating thickness measurement, adhesion testing, pressure testing

Performance Under Extreme Conditions

| Environmental Condition | Test Standard | Performance Rating | Expected Service Life |

|---|---|---|---|

| Marine Atmosphere (C5-M) | ISO 9227 | Excellent (2,000+ hours salt spray) | 10-12 years |

| Industrial Environment (C4) | ASTM B117 | Very Good (1,500 hours) | 12-15 years |

| Chemical Exposure (pH 3-10) | ASTM G31 | Good (limited chemical resistance) | 8-10 years |

| High Temperature (up to 400°C) | ASTM E119 | Good (zinc coating stability) | 7-9 years |

Galvanized Fin Tubes Future Applications

Renewable Energy Systems: Galvanized Fin Tubes are increasingly used in biomass boilers and waste heat recovery systems, where corrosion resistance and thermal efficiency are critical.

Data Center Cooling: Major technology companies are adopting galvanized fin tube heat exchangers for their superior performance in high-humidity environments, achieving 18-22% energy savings in cooling systems.

Automotive Industry: Heavy-duty vehicle manufacturers report 25% improvement in radiator efficiency and extended service life in road salt environments.

Expert Recommendation

For optimal performance, specify zinc coating thickness of 80+ microns and verify compliance with ASTM A123 standards. Regular inspection intervals of 24-36 months are recommended for critical applications.

Galvanized Fin Tubes Economic Benefits

The economic benefits of Galvanized Fin Tubes extend beyond initial cost savings:

| Cost Factor | Traditional Tubes | Galvanized Fin Tubes | Savings |

|---|---|---|---|

| Initial Installation | $100,000 | $125,000 | -$25,000 |

| Annual Maintenance | $18,000 | $6,000 | $12,000 |

| Replacement Costs (5-year) | $85,000 | $0 | $85,000 |

| Energy Savings (Annual) | $0 | $8,500 | $8,500 |

| 5-Year Total Cost | $275,000 | $163,500 | $111,500 |

Return on Investment: Most industrial applications achieve payback within 18-30 months, with continued savings throughout the 12+ year service life.

Galvanized Fin Tubes

Our thermal engineering specialists are available to review your specific application requirements and provide customized recommendations.

Contact Our Engineering Team

Technical Disclaimer: Performance data based on industry averages and specific application testing. Actual results may vary based on operating conditions, maintenance practices, and environmental factors. Consult with qualified engineers for project-specific recommendations.