Why use H type finned tube in boiler economizer?

Why use H type finned tube in boiler economizer?

This article introduces and analyzes the exceptional features of H-type finned tubes used in boiler economizers, focusing on their resistance to ash deposition and wear. The high-efficiency H-type finned tubes are installed on the tail flue of the boiler, offering excellent economy and practicality while significantly improving the thermal efficiency of the boiler economizer. As a result, they have gained wide usage in economizers of large coal-fired industrial boilers. Furthermore, the article explores the application of H-type finned tube economizers in waste heat recovery equipment through an engineering example, providing a calculation formula for heat transfer and resistance of H-type finned tubes.

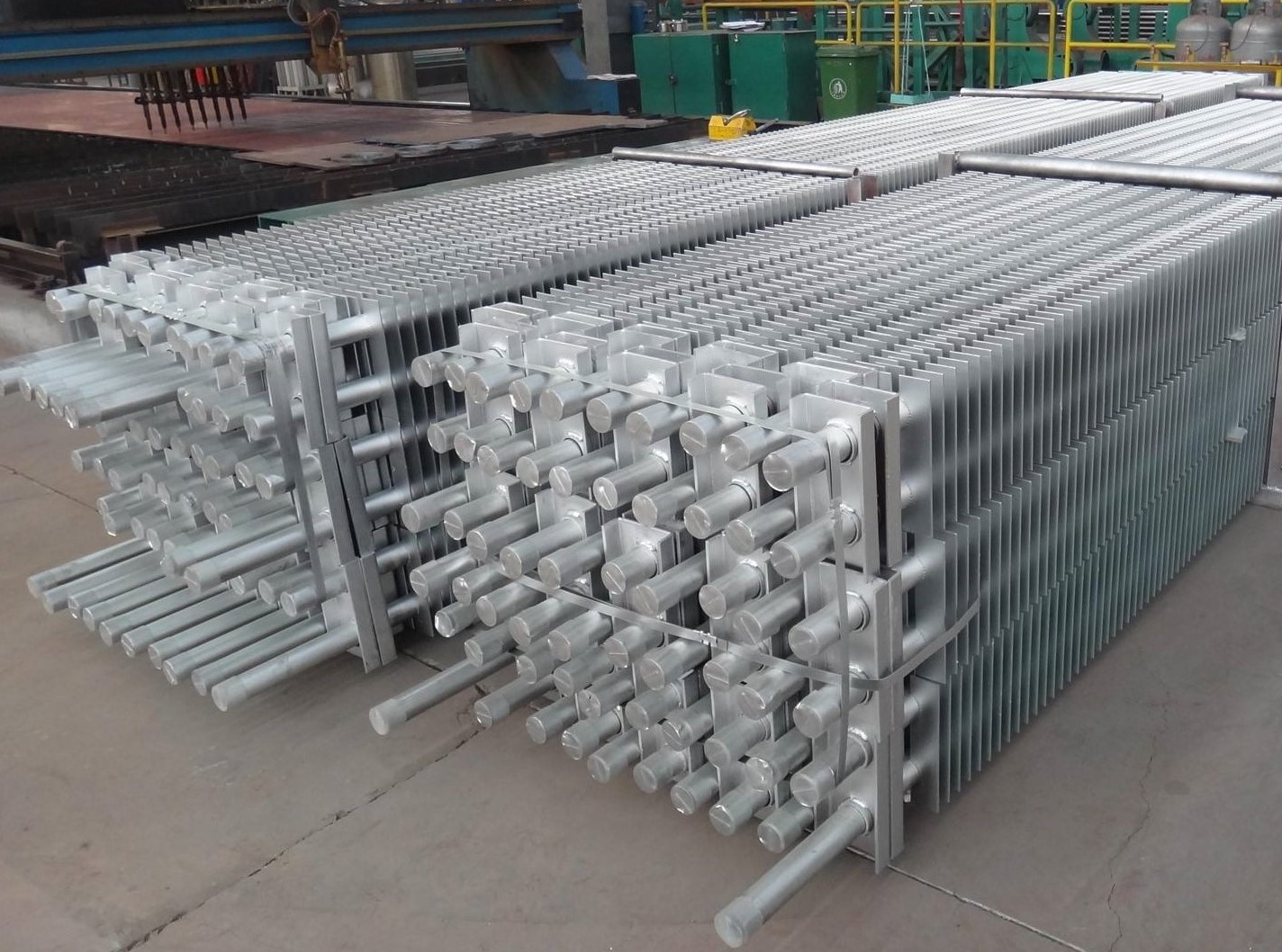

H-finned tube economizer, also known as an economizer, utilizes H-finned tubes (also referred to as H-fin tubes, double finned tubes, or butterfly tubes) assembled into a highly efficient heat exchanger economizer. The structure primarily consists of "H" type and double "H" type configurations in an in-line arrangement.

H-Type Finned Tubes Performance Characteristics:

1) Enhanced Heat Transfer: H-finned tube economizers offer a larger heat transfer area compared to traditional economizer tubes, reducing the required number of tubes and enabling an increase in flue gas flow cross-section. This lowers the flue gas velocity, minimizing wear and tear. The wear rate and flue gas pipe power have a proportional relationship of 3.33. By reducing the flue gas velocity from 9m/s to 7m/s, the wear rate can be reduced by 43%. Additionally, experiments have shown that the finned tube design helps centralize fly ash deposition, further reducing structural wear.

2) Double "H" Type Configuration: H-type finned tubes can be produced in a "double H" type design, which enhances structural rigidity and is suitable for longer tube row applications.

3) Optimized Airflow: The line layout of H-type finned tube economizers divides the H-fin space into several smaller areas, promoting better airflow distribution and greatly reducing wear.

4) Improved Sootblower Effectiveness: The straight channel formed by the H-type fins on both sides of the tubes enables the best performance of sootblowers, facilitating efficient cleaning.

5) Compact and Cost-effective: The compact design of H-finned tube economizers significantly reduces overall weight and lowers costs.

6) Energy Efficiency and Low Power Consumption: H-finned tube economizers contribute to energy savings by reducing heat losses. For economizer generator sets, they can lower heat losses by at least two-thirds, resulting in a consumption of only 2-4 kW per ton of steam.

7) Simplified Operation and Maintenance: H-finned tube economizers are easy to operate and maintain, requiring minimal labor. The factory assembly and simple structure make installation straightforward. The high level of automation further reduces the need for operating personnel.

Parameters of H-finned Tube Economizers:

- Steam Pressure: 0.5 ~ 4.0 MPa

- Steam Forms: Saturated Steam / Superheated Steam

Cycle Modes of H-finned Tube Economizers:

- Natural Circulation / Forced Circulation

Adaptation Range of H-finned Tube Economizers:

- Suitable for power ranges of 600 kW ~ 15,000 kW in various types of generating units and for waste heat resources with temperatures above 300 ℃.

By presenting this comprehensive overview of H-type finned tube economizers, the article aims to highlight their benefits and wide-ranging applications in the field of boiler economizers and waste heat recovery equipment.