Introduce High-fin heat exchange tube

2024-03-22Leave a message

Introduce High-fin heat exchange tube

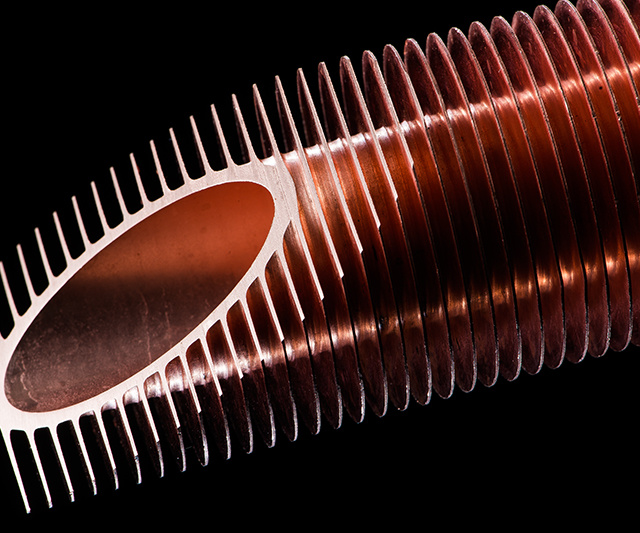

High finned heat exchange tube is a tubular heat exchange element that increases the surface area and improves heat transfer efficiency by processing or welding additional fins on the outer surface of the light tube. Its basic structure is a series of high fins evenly distributed on the outer wall of the tube, which greatly increases the heat exchange area between the fluid flowing through the surface of the fins and the fluid inside the tube, thereby improving the heat transfer effect. High finned heat exchange tubes are commonly used in process environments that require efficient heat transfer, especially in gas and liquid heat exchange processes, and have significant energy-saving effects.

A high-fin heat exchange tube comprises a tube body and helical fins. The feature is: spiral fins are formed with first and second fold-out wings, both having the same fold-out direction and connected by arc transition fins. The cavities between adjacent first fold-out wings of each pair of spiral fins form the airflow chamber of the first fold-out wing, while the cavities between adjacent second fold-out wings of each pair of spiral fins form the airflow chamber of the second fold-out wing. The airflow chamber of the first fold-out wing communicates with the spiral fin groove and the arc transition fin groove, and the airflow chamber of the second fold-out wing also communicates with the spiral fin groove and the arc transition fin groove. The chord length of the first fold-out wing is equal to the chord length of the second fold-out wing, and the sum of the chord lengths of the first and second fold-out wings and the arc length of the arc transition fin accounts for two-thirds to one-half of the circumference of the spiral fin. There is no contact thermal resistance between the tube body and the root of the helical fins, which enhances heat exchange efficiency and saves energy.

The new high-fin heat exchange tube provides a structure that integrates the fins with the tube body to eliminate contact thermal resistance between the tube body and the root of the helical fins, conducive to inducing airflow direction changes and creating good disturbance effects to improve heat exchange efficiency and demonstrate energy saving.

The effects of the new high-fin heat exchange tube are as follows:

Firstly, because the helical fins extend radially from the material on the tube body and spiral around the outer surface of the tube body in the circumferential direction of the tube body, forming an integral structure with the tube body, there is no contact thermal resistance between the tube body and the root of the helical fins;

Secondly, the formation of first and second fold-out wings on the helical fins creates airflow chambers conducive to inducing airflow direction changes and producing good disturbance effects on the airflow, thereby improving heat exchange efficiency and demonstrating energy saving;

Thirdly, when this utility model is installed in a boiler or similar heating facility in the operating state, the airflow forms a plurality of S-shaped flows, thereby improving heat exchange efficiency and saving energy consumption.