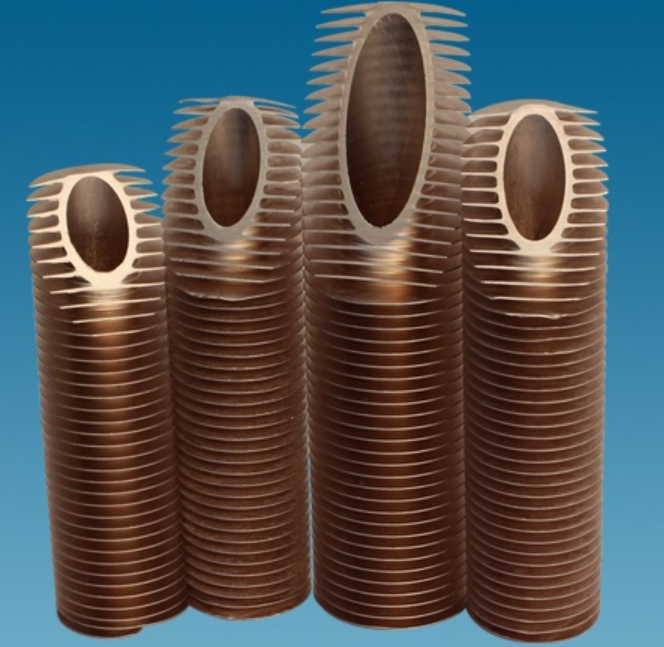

C12200 High fin heat exchange tubes

What are C12200 high fin heat exchange tubes?

C12200 is a specific type of copper alloy that is commonly used in the production of high-fin heat exchange tubes. These tubes are designed for efficient heat transfer applications, particularly in industries such as HVAC (heating, ventilation, and air conditioning), refrigeration, and power generation.

Here are some key features and characteristics of C12200 high-fin heat exchange tubes:

1. C12200 High fin heat exchange tubes Material Composition:

C12200 is a copper alloy with a high copper content of approximately 99.9%. It also contains a small amount of phosphorus, which helps improve the alloys mechanical properties.

2. C12200 High fin heat exchange tubes thermal Conductivity:

Copper is known for its excellent thermal conductivity, and C12200 is no exception. It enables efficient heat transfer between the fluid inside the tube and the surrounding environment.

3. C12200 High fin heat exchange tubes corrosion resistance:

Copper alloys, including C12200, possess good corrosion resistance. They are resistant to various forms of corrosion, such as general corrosion and pitting corrosion, making them suitable for prolonged use in different environments.

4. C12200 High fin heat exchange tubes high-fin design:

High-fin heat exchange tubes refer to tubes with extended surfaces or fins along the outer surface. These fins increase the surface area available for heat transfer, thereby enhancing the overall heat exchange efficiency.

5. C12200 High fin heat exchange tubes applications:

C12200 high-fin heat exchange tubes are widely used in heat exchangers, air coolers, condensers, and evaporators. They are commonly employed in HVAC systems, refrigeration units, power plants, and industrial processes where efficient heat transfer is crucial.

6. C12200 High fin heat exchange tubes manufacturing:

The production of C12200 high-fin heat exchange tubes involves processes such as extrusion, forming the tube shape, and then applying fins to the outer surface. The fins can be either integral (formed from the same material as the tube) or externally applied.

Its worth noting that while C12200 is a popular choice for high-fin heat exchange tubes, there are other copper alloys and materials available for similar applications. The specific alloy selection depends on factors such as operating conditions, required corrosion resistance, thermal conductivity, and manufacturing considerations.